Temperature control method for magnesium alloy pressure casing die

A temperature control method and die-casting mold technology, which is applied in the field of temperature control of die-casting molds, can solve problems such as ineffective control of mold temperature and uncontrollability, and achieve the effects of reducing deformation, flexible control, and ensuring casting quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

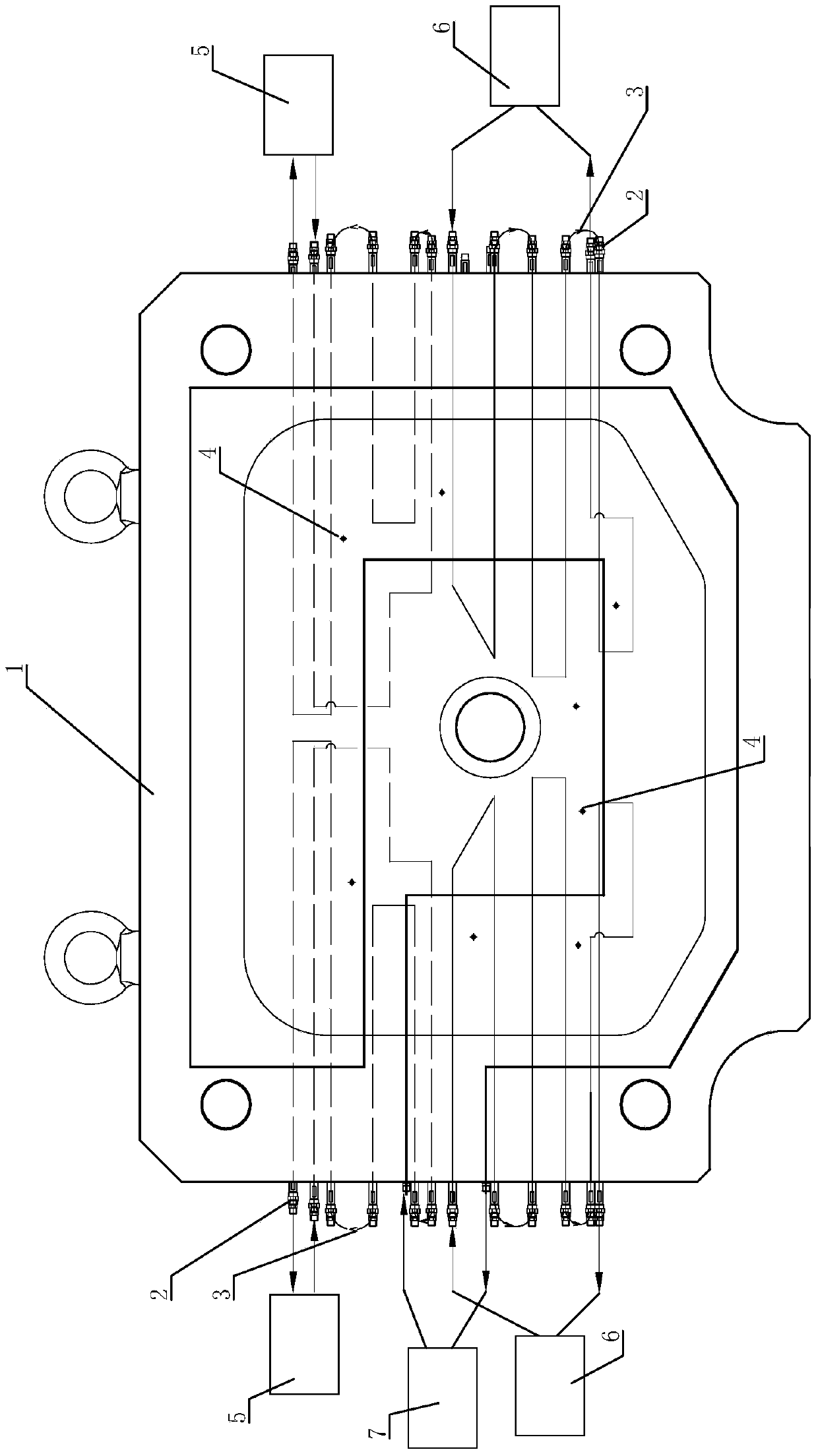

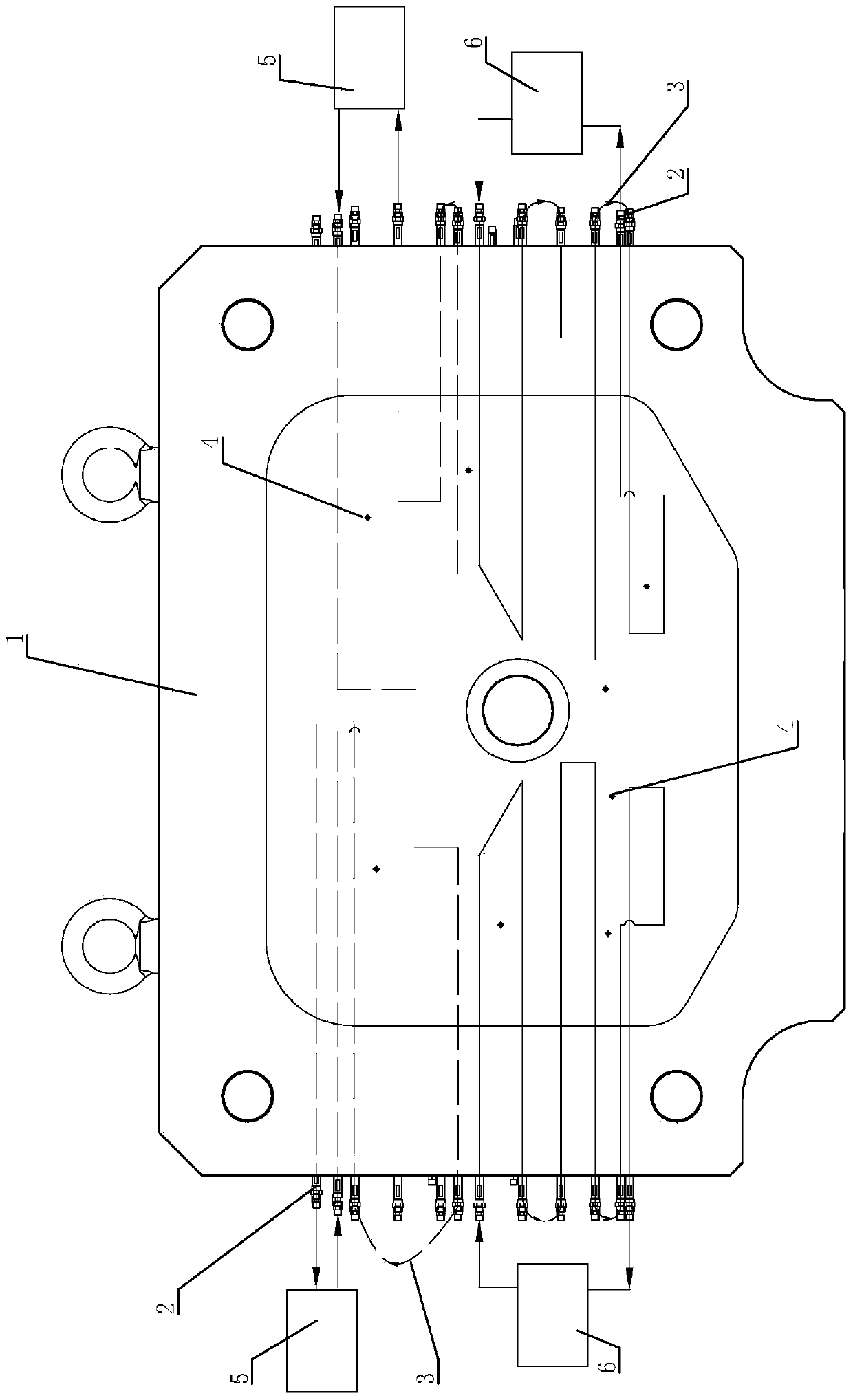

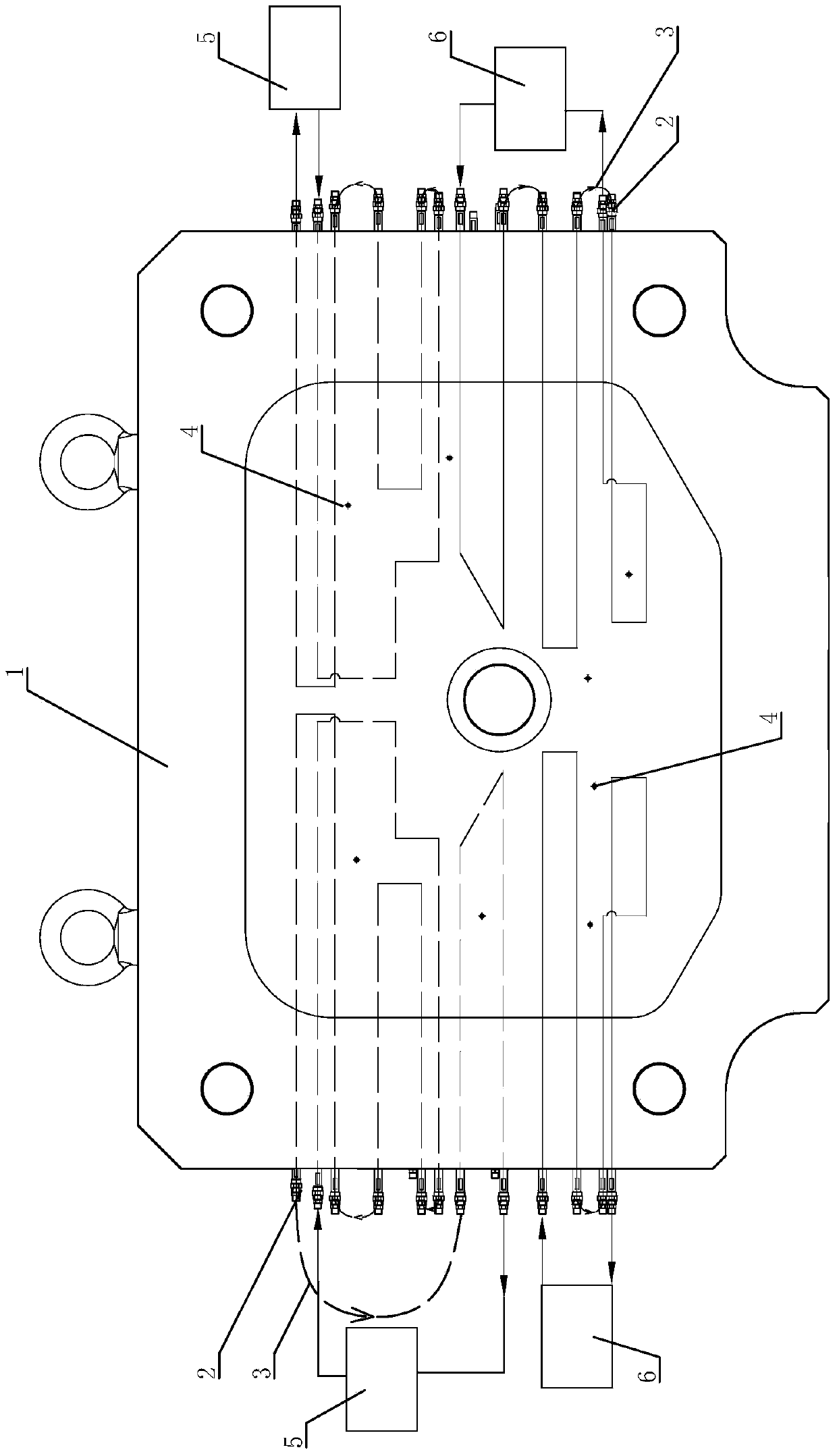

[0017] Such as Figure 1-Figure 4 As shown, including the mold 1, there are several oil ports 2 on the left and right sides of the mold 1, and two of the oil ports on each side communicate through the pipeline embedded in the mold 1 and form a set of oil guide passages , one of the oil ports is used as the inlet, and the corresponding other oil port is used as the outlet.

[0018] Such as figure 1 As shown, in the first embodiment, every three sets of oil guide passages are connected in series through the oil pipes 3 installed externally on the corresponding oil ports and connected to a mold temperature controller to form an oil circuit cycle. According to the key points in casting molding The area is divided into several temperature control zones at the corresponding positions of the mold 1, and each temperature control zone is formed by the covering part of each oil circuit circulation in the mold body. According to the shape characteristics of the casting, the mold 1 in E...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com