Heating method and device before corrugated paperboard adhesion

A heating device and corrugated cardboard technology, which is applied in the direction of machining/deformation, can solve the problems of poor bonding effect and insufficient heating temperature, and achieve the effect of good bonding, high quality, and fast glue gelatinization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be described in detail below in conjunction with the accompanying drawings.

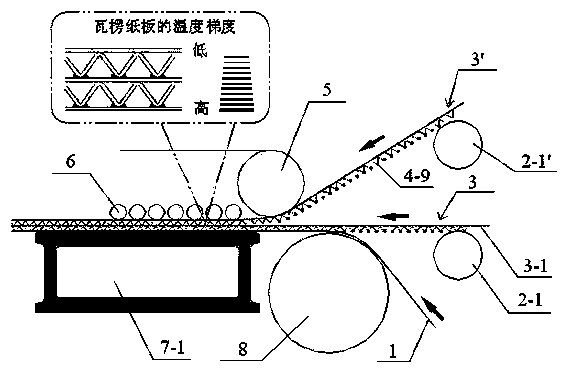

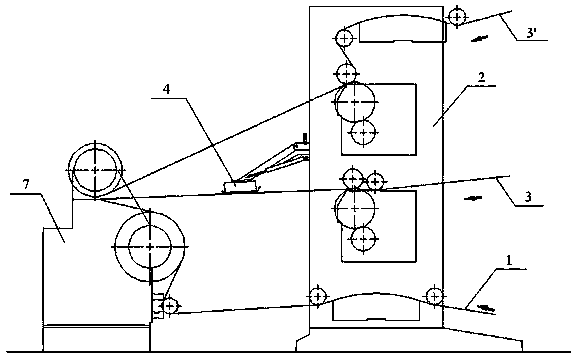

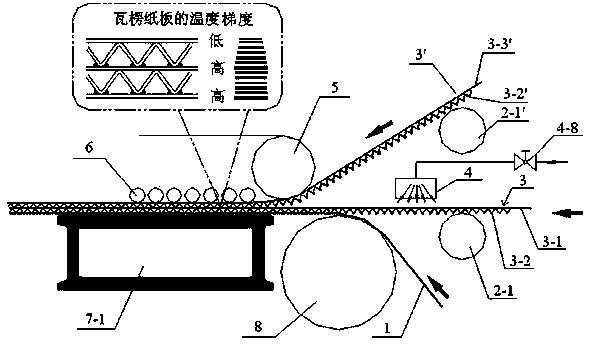

[0037] see figure 2 In order to overcome the existing problems of heat transfer layer by layer in the existing heating method, the method of the present invention is to provide a heating device 4 at the position before entering the double-sided machine 7 after the gluing machine 2, and the heating device 4 only heats the single side. The middle paper in the corrugated paper is directly heated. In this way, before entering the double-facer, the middle paper is heated to make it preheated, and then enters the double-facer and is heated by the hot plate of the double-facer, so that the overall temperature of the corrugated cardboard is balanced and the bonding effect is guaranteed. It overcomes the problem in the prior art that the bonding effect of the part far away from the hot plate of the double-sided machine is not good.

[0038] As far as the specific technica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com