Activated carbon column purification method

An activated carbon column and purification method technology, applied in chemical instruments and methods, separation methods, organic chemistry, etc., can solve the problems of easy clogging of activated carbon columns, prone to channeling, column pressure, etc., and achieve safe operation and high purification efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] In the stainless steel column, add powdered activated carbon with a size of 400 meshes, control the temperature in the column at 50°C, and the pressure at 0.05Mpa, prepare a 30% weight concentration of the compound to be purified isoacetic acid ester solution, and control the material feed rate 0.5cm / min, feed from the bottom of the column, after the feed liquid comes out from the top of the column, collect the qualified feed liquid.

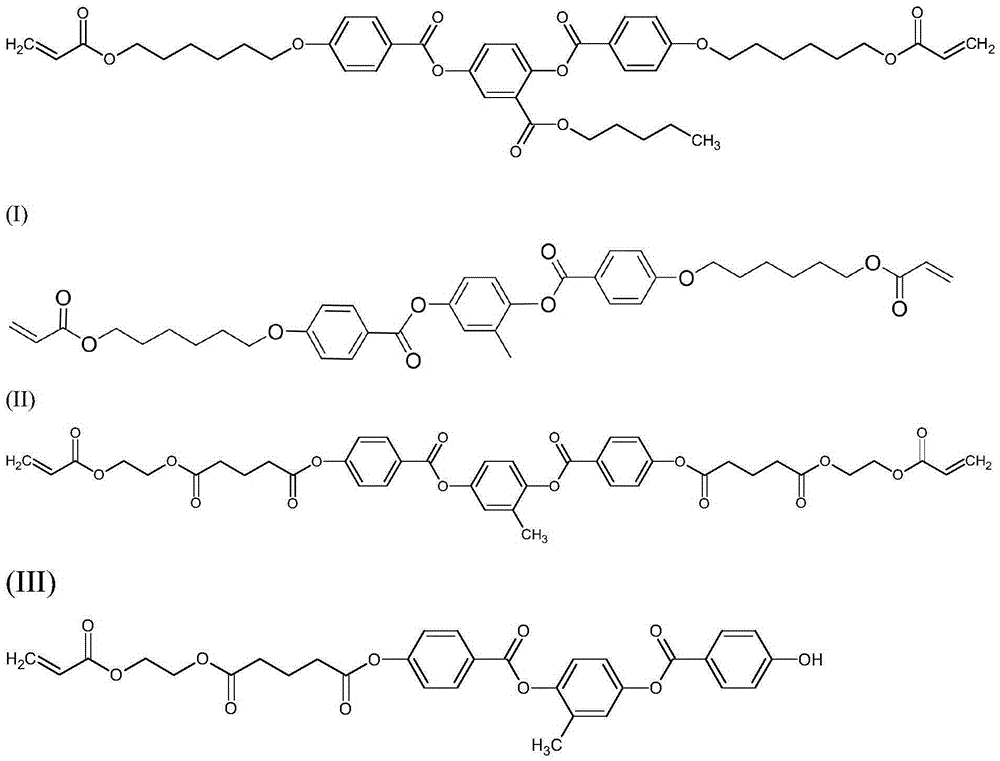

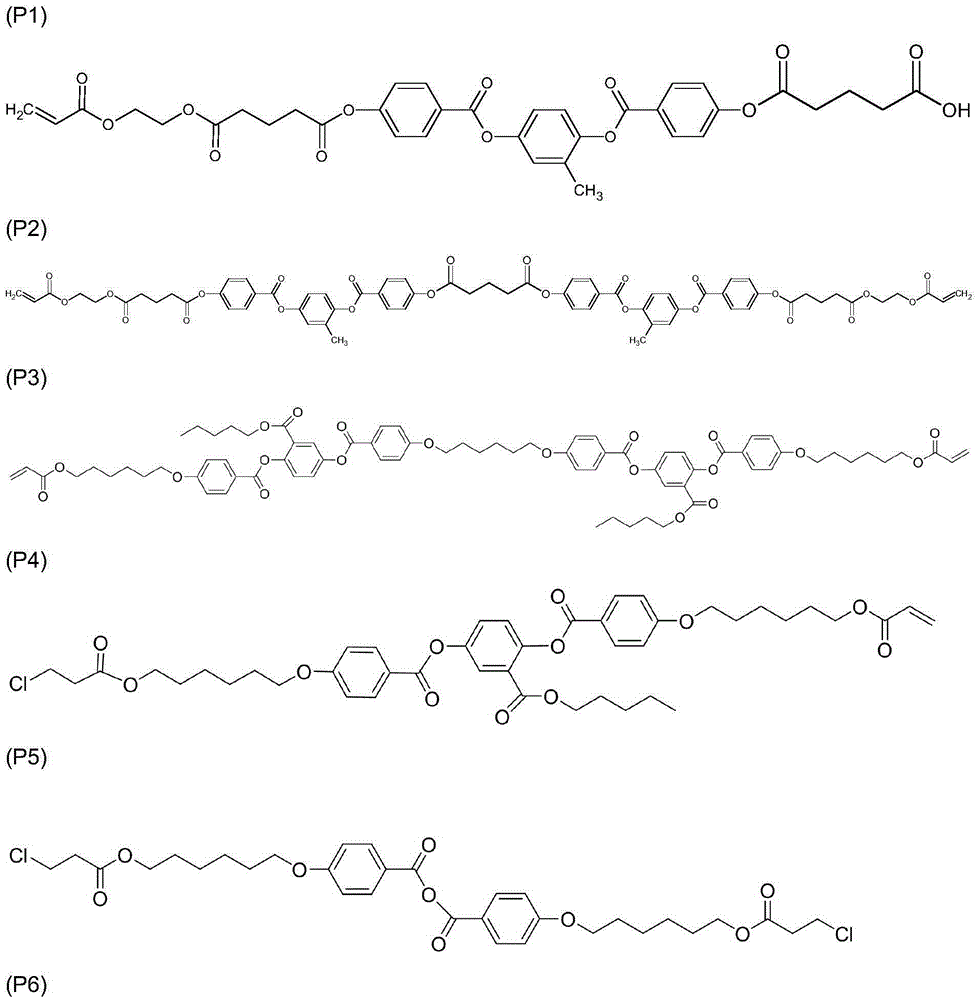

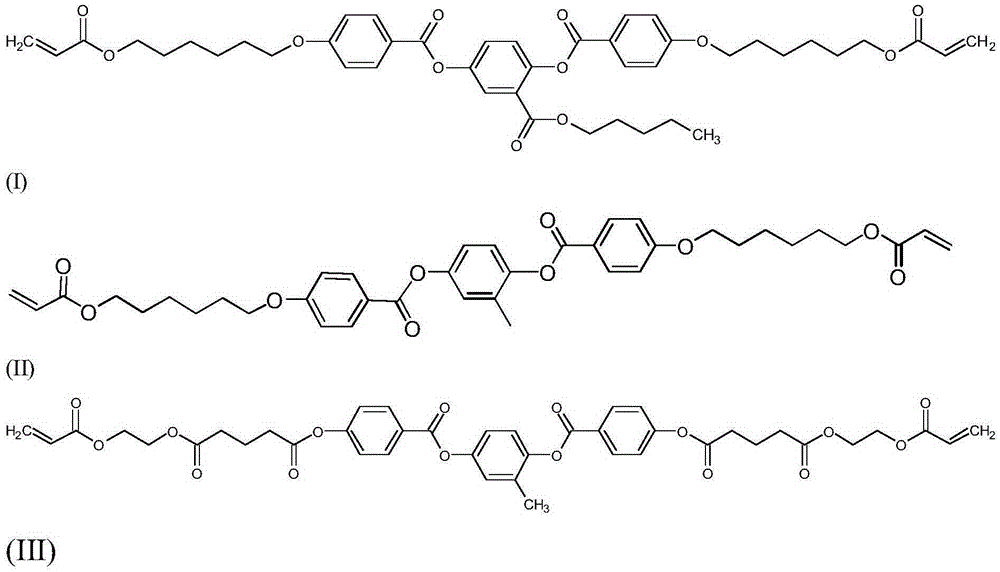

[0028] The iso-acetate solution to be purified with a weight concentration of 30% is a solution containing compound (I), and the impurities therein are P1, P2, and P3.

Embodiment 2

[0030] In the stainless steel column, add powdered activated carbon with a size of 400 mesh, control the temperature inside the column at 50°C, and the pressure at 0Mpa (gauge pressure), prepare a solution of the compound to be purified with a weight concentration of 60%, and control the feed rate of the material 0.2cm / min, feed from the bottom of the column, after the feed liquid comes out from the top of the column, collect the qualified feed liquid.

[0031] The iso-acetate solution to be purified with a weight concentration of 60% is a solution containing the compound (II), and the impurities therein are P3, P4, and P5.

Embodiment 3

[0033] In the stainless steel column, add powdered activated carbon with a size of 200 mesh, control the temperature in the column at 80°C, and the pressure at 2Mpa (gauge pressure), prepare a solution of the compound to be purified with a concentration of 30%, and control the feed rate of the material to be 0.4cm / min, feeding from the bottom of the column, after the feed liquid comes out from the top of the column, collect the qualified feed liquid.

[0034] The isoacetic acid ester solution to be purified with a weight concentration of 30% is a solution containing the compound (III), and the impurities therein are P1 and P6.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com