Monitoring and operating three-chamber vacuum furnace

A vacuum furnace and vacuum pumping technology, which is applied in the field of monitoring and operating a three-chamber vacuum furnace, can solve the problems of serious heat dissipation, oil splashing, uneven heating of the oil surface, etc., and achieve the effects of reducing heat energy loss, heat energy loss isolation, and improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

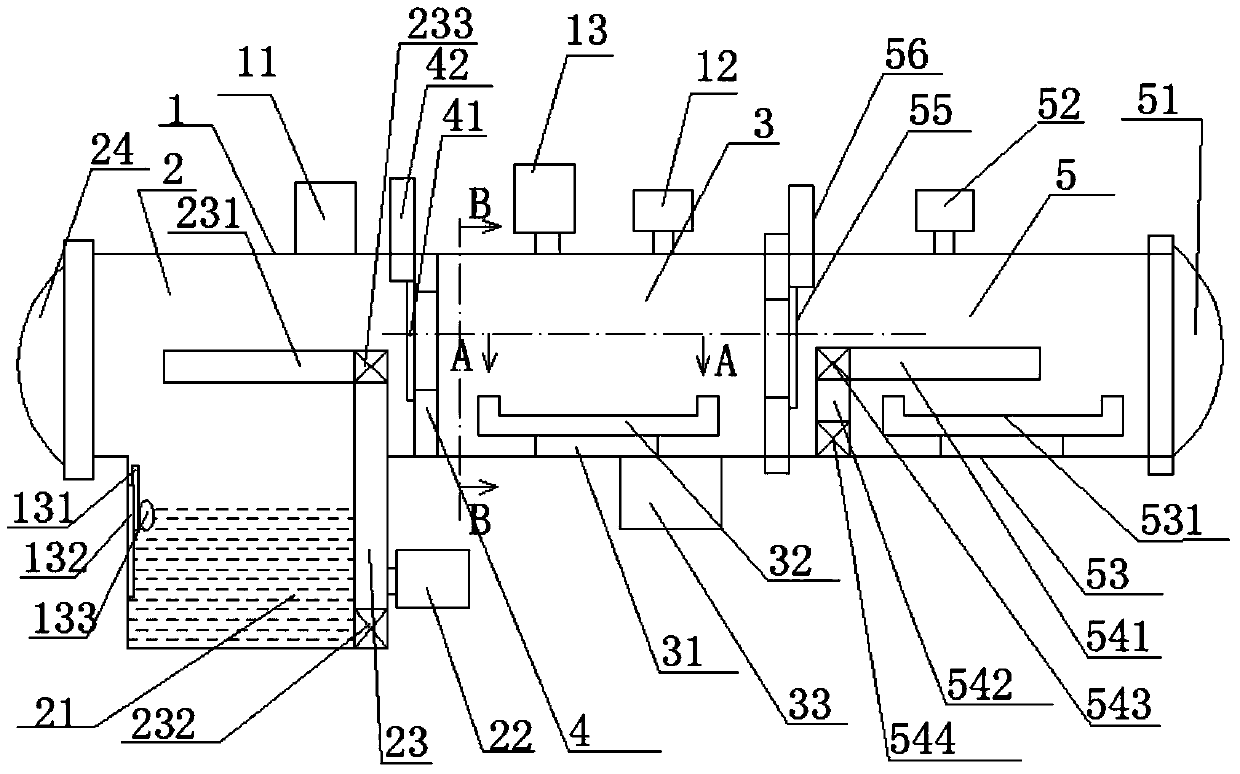

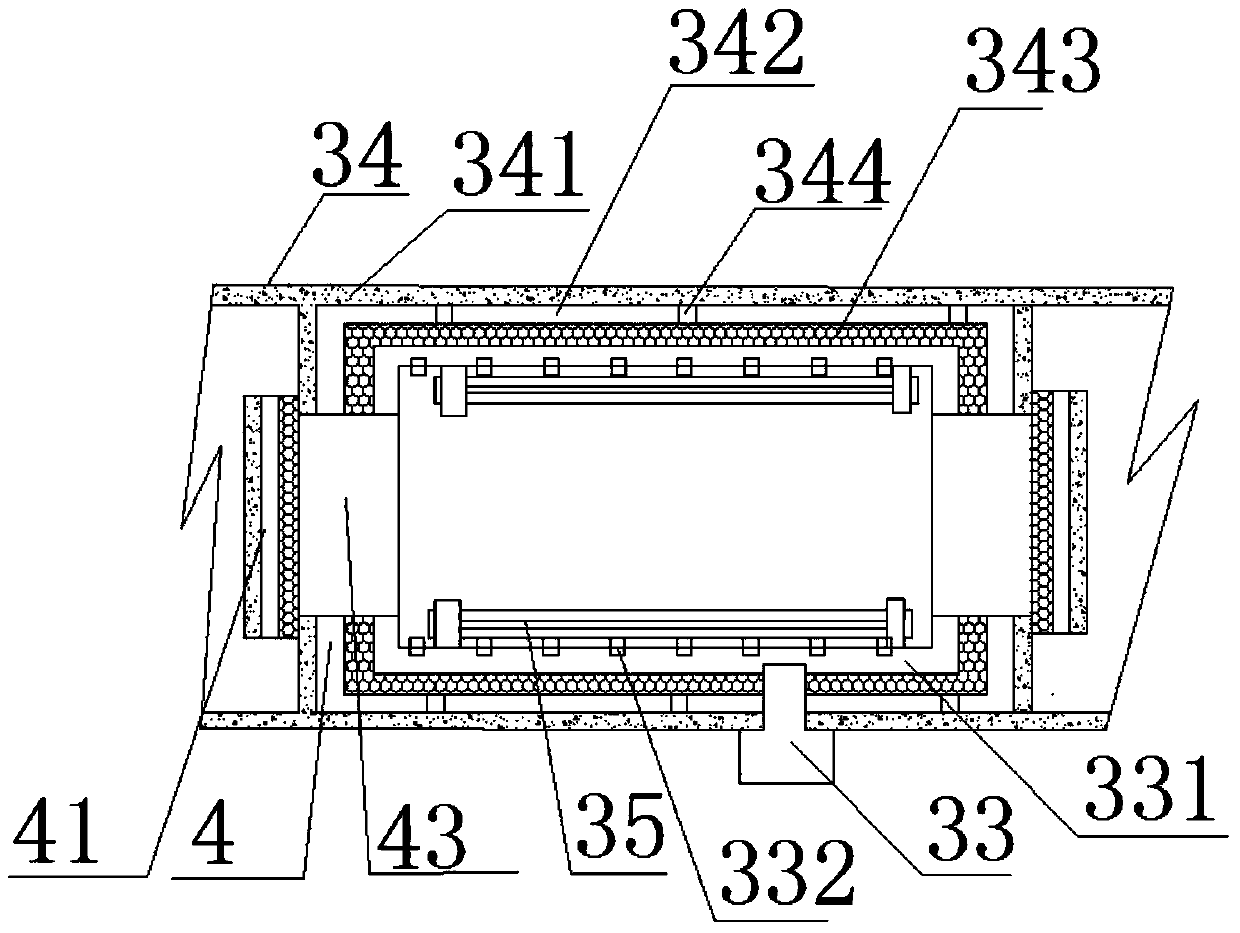

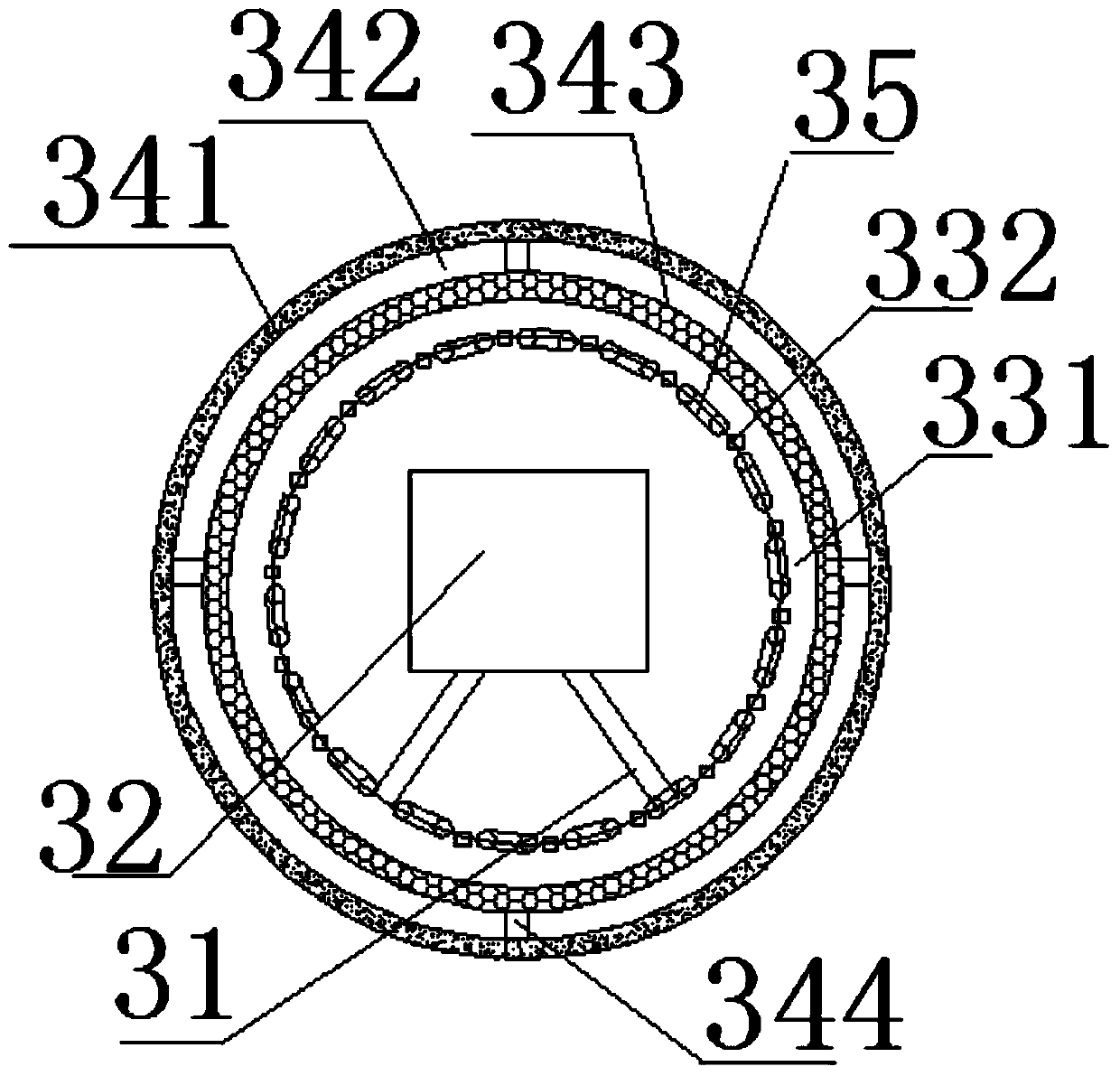

[0032] A kind of monitoring operation three-chamber vacuum furnace of this embodiment, such as Figure 1-3 As shown, it includes a furnace body shell, and the furnace body shell is provided with a cooling chamber and a heating chamber, and also includes a preparation room, and the preparation room, heating chamber, and cooling chamber are sequentially arranged in the furnace body shell according to the flow direction of material processing, and The preparation chamber, the heating chamber and the cooling chamber are respectively connected with a vacuum pumping mechanism, and at the same time, both sides of the heating chamber are respectively connected with the preparation chamber and the cooling chamber through the partition wall; the partition wall is provided with a partition wall inlet and outlet , the inlet and outlet of the compartment wall are equipped with insulating doors, and the insulating doors are located on the side of the compartment wall away from the heating ch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com