Drawing frame

A drawing frame and sliver technology, applied in spinning machines, textiles and papermaking, drafting equipment, etc., can solve the problem of inability to output whiskers, and achieve the effects of simple structure, convenient use and strong industrial applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

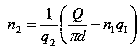

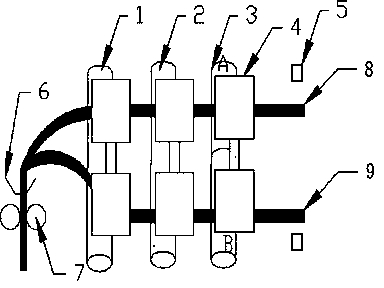

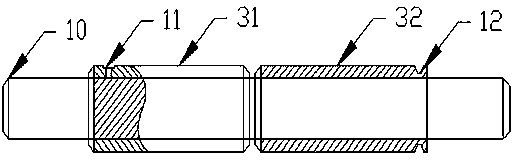

[0022] Use drawing frame of the present invention, and merge polyester, cotton sliver according to the method of the present invention. The main process parameters are: 8 polyester and cotton slivers, the initial feeding mass ratio is 50 / 50; the polyester sliver is fed from the rear roller A area, the cotton sliver is fed from the rear roller B area, and the left stepping motor M 1 The number of pulses N 1 Change according to the law of sinusoidal curve; right stepping motor M 2 The number of pulses N 2 according to changes in the law. On the control panel, set the total draft multiple of the draw frame, and the left stepping motor M 1 , right stepping motor M 2 The starting speed is n 0 , and then start the draw frame, when the left stepper motor M 1 with the right stepper motor M 2 The speed reaches n 0 When, the left stepper motor M 1 The speed changes according to the sinusoidal law from n 0 →2n 0 →n 0 →0, right stepping motor M 2 at the speed of The regul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com