Rapid rectangular full-face tunnel boring machine for mining

A roadheader, full-section technology, used in cutting machinery, earthwork drilling, etc., can solve the problems of requiring many workers, slow driving speed, poor roadway quality, etc., to increase the scope of application, improve stability, and improve driving. effect of efficacy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The preferred embodiments of the present invention are given below in conjunction with the accompanying drawings to describe the technical solution of the present invention in detail.

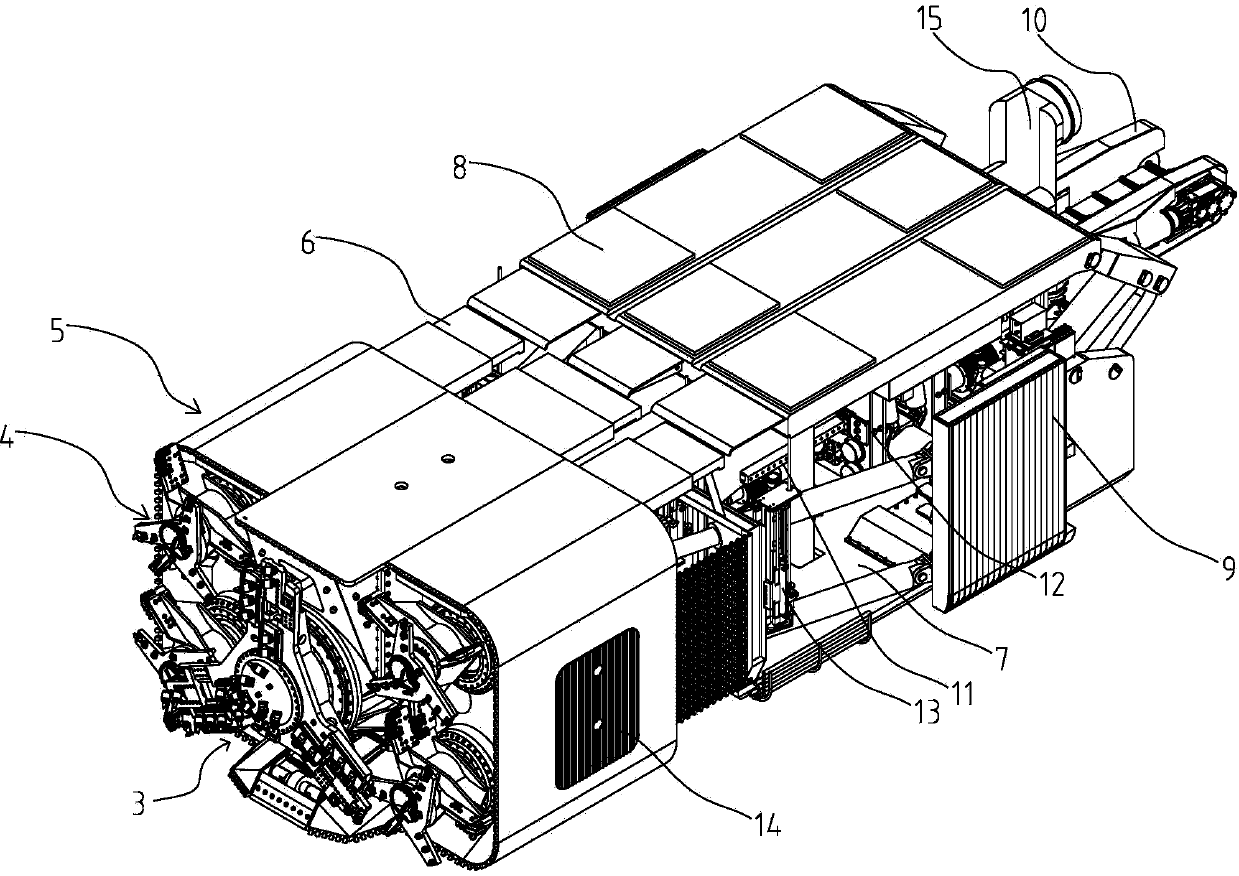

[0037] figure 1 It is a schematic diagram of the overall structure of the present invention. The entire mining full-section rectangular rapid roadheader includes the following mechanisms: roadheader head 5, rear telescopic cover beam 6, support propulsion mechanism 8, support propulsion mechanism 9, scraper conveyor 10, guiding main beam 11, saddle frame adjustment mechanism 12. Advance support bolt unit 13, front support shoe 14 and dust removal system 15, etc.

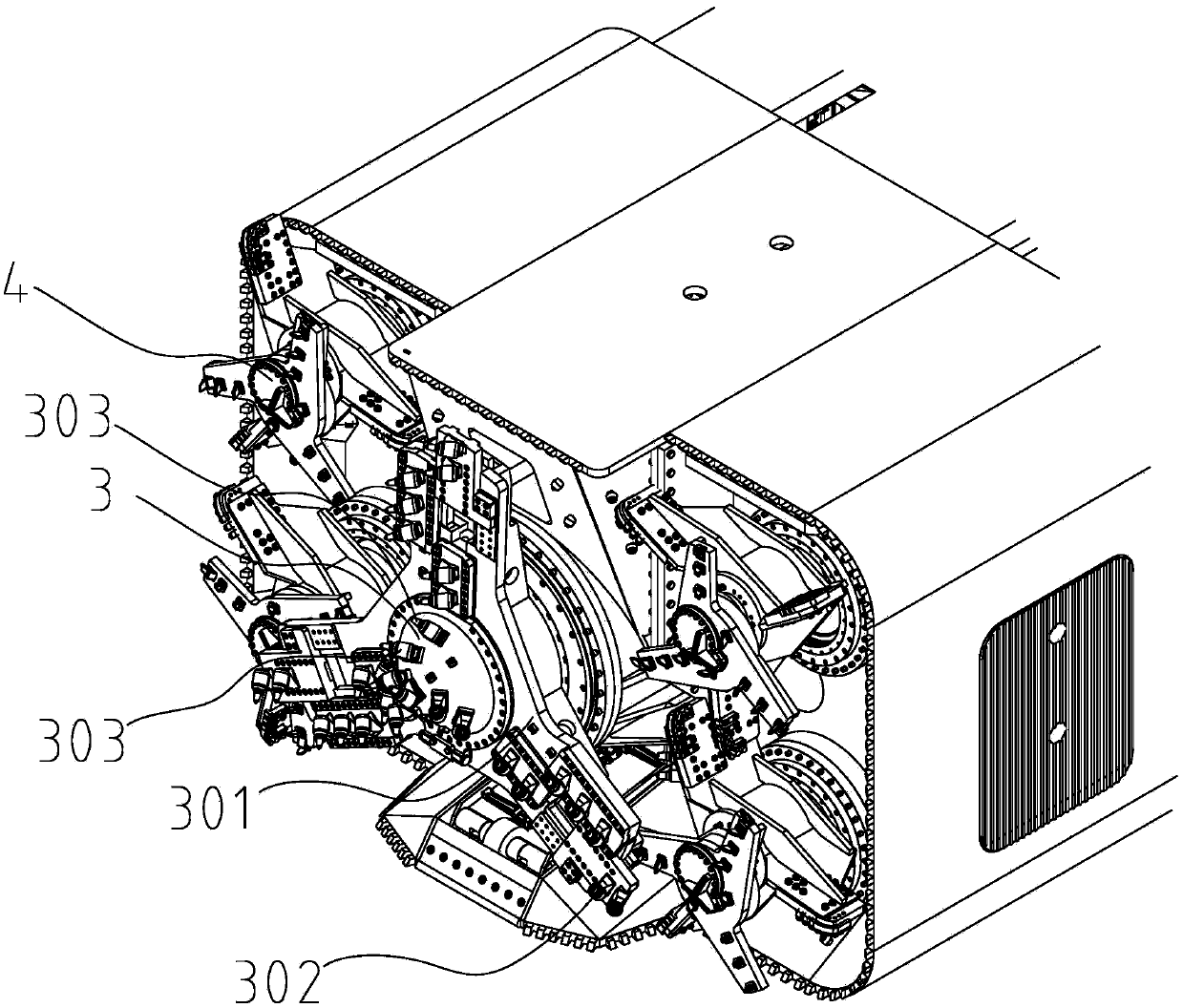

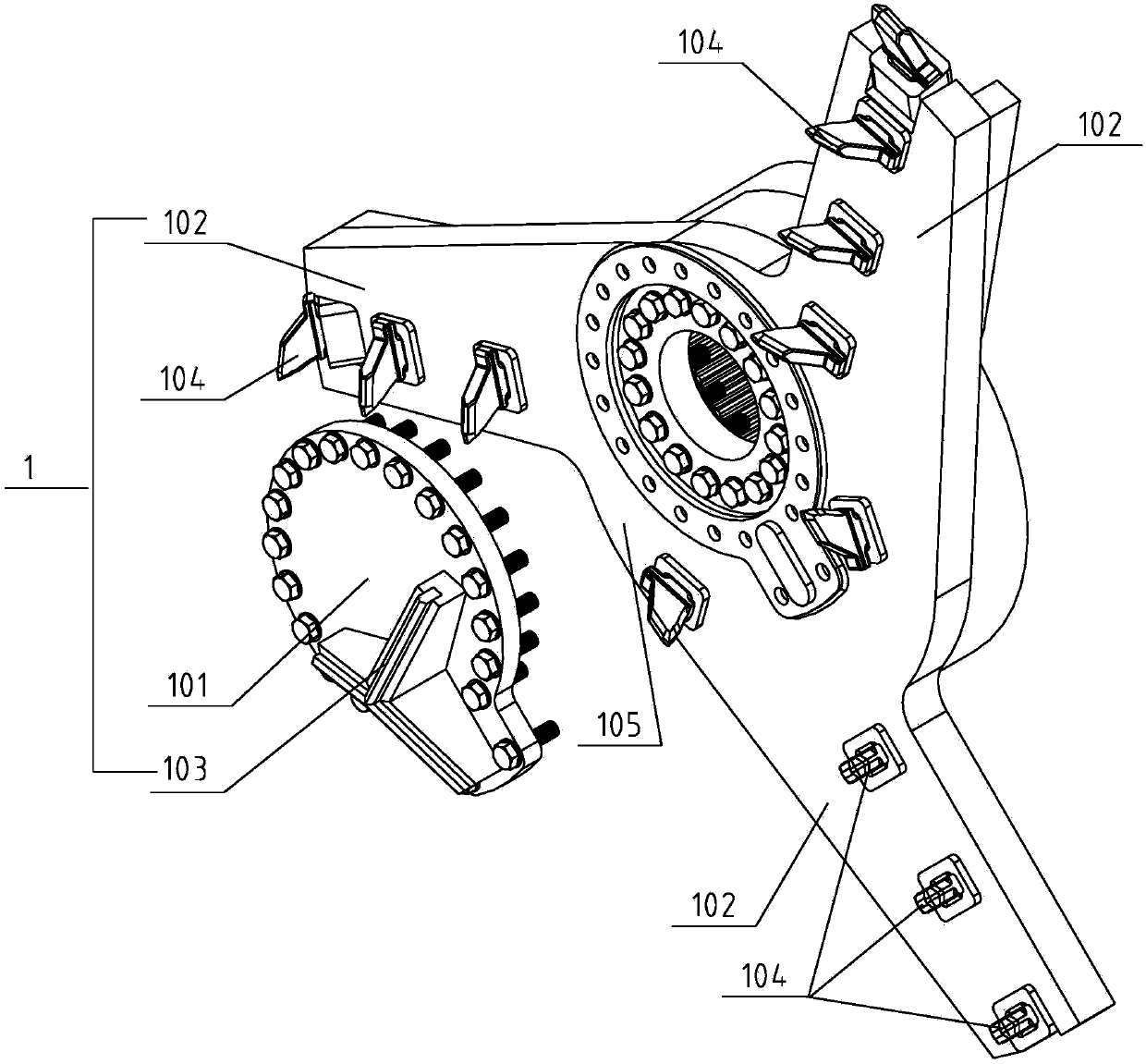

[0038] The head 5 of the roadheader is located at the front end of the full-section rectangular fast roadheader for mining. The head of the roadheader adopts a composite layer combined cutterhead, which includes a central large cutterhead 3 and four surrounding small cutterheads 4 , a large central cutterhead 3 protrudes forw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com