Pressuring riveting and rising riveting integrated nut and combination and riveting technology thereof

A nut and riveting technology, applied in the direction of nuts, connecting members, threaded fasteners, etc., can solve problems such as falling off and rotation, and achieve the effects of low cost, simple structure and process, and improved riveting torque and riveting strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

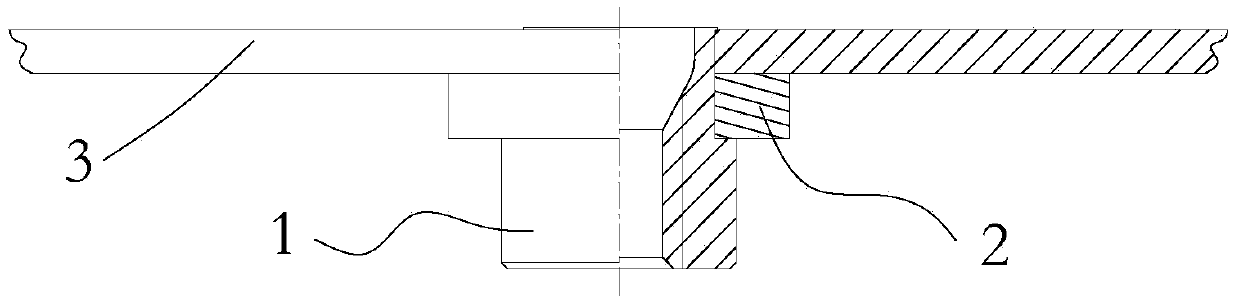

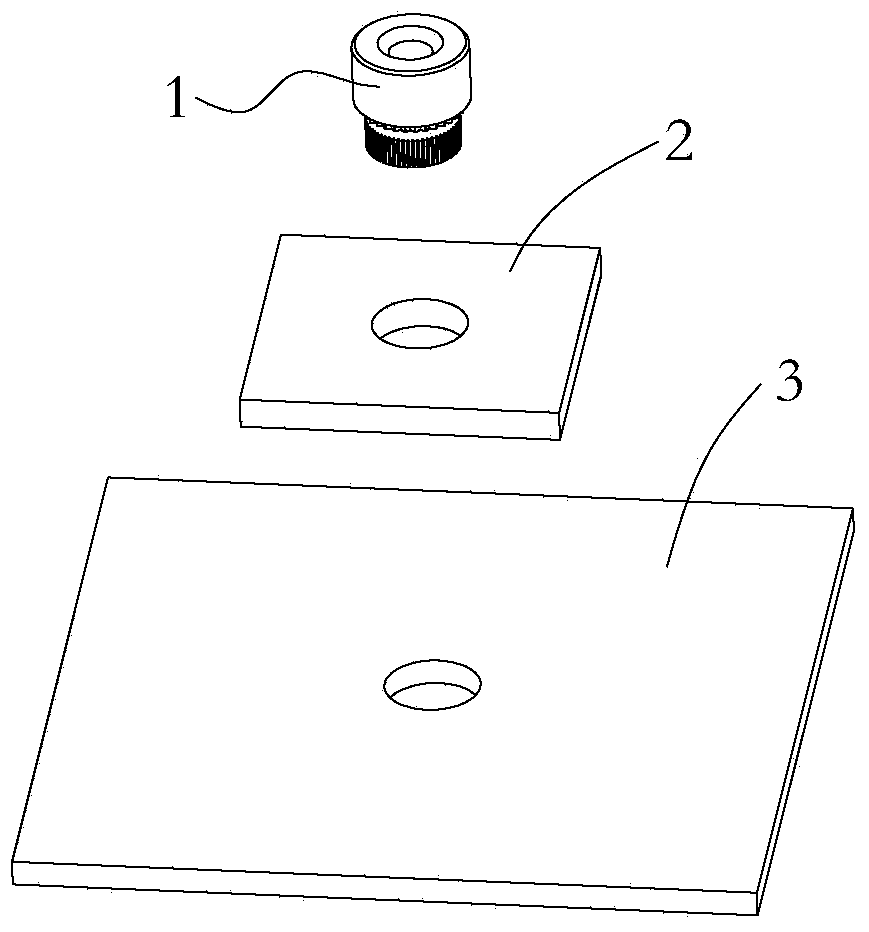

[0020] The present invention will be further described below with reference to the accompanying drawings and exemplary embodiments, wherein the same reference numerals in the accompanying drawings all refer to the same components. Also, detailed descriptions of known arts will be omitted if they are unnecessary to illustrate the features of the present invention.

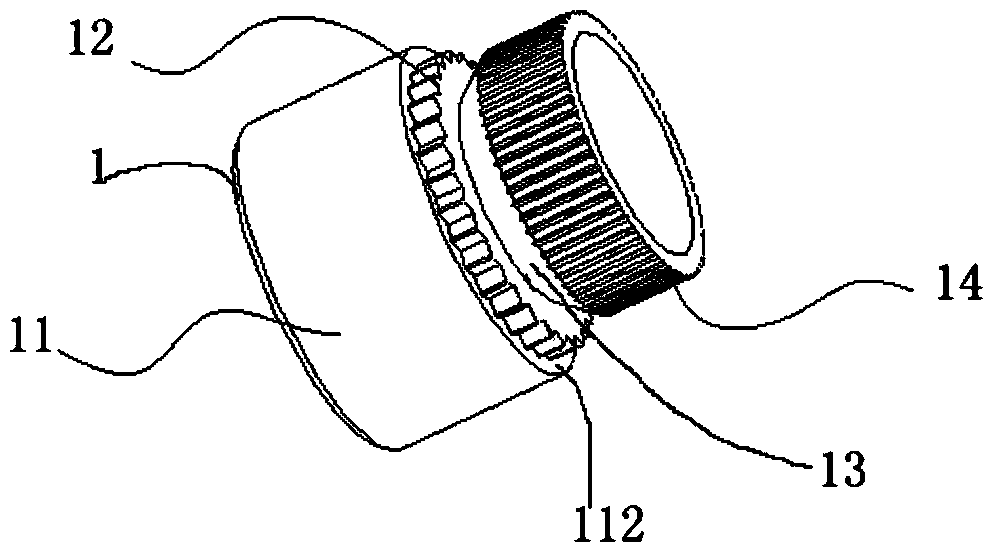

[0021] Such as figure 1 As stated above, the present invention relates to a compression riveting integrated nut 1, which is made of stainless steel and specifically includes:

[0022] A nut section 11 with a lower end surface 112, used for fastening with bolts (not shown); the first knurled section 12 provided on the lower end surface 112 of the nut section 11; provided on the first knurled section the second knurled segment 14 on 12; and the groove segment 13 formed between the first knurled segment 12 and the second knurled segment 14.

[0023] The first knurling section 12 and the second knurling section 14 are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com