Leveling device for suspension equipment

A technology for leveling devices and suspension equipment, which is applied in the direction of mechanical equipment, supporting machines, machine platforms/supports, etc., which can solve problems such as the inability to accurately meet the installation accuracy of mechanism boxes, easy damage to equipment components, and waste of manpower and material resources, so as to improve installation The effect of process quality, saving operating cost and reducing work intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

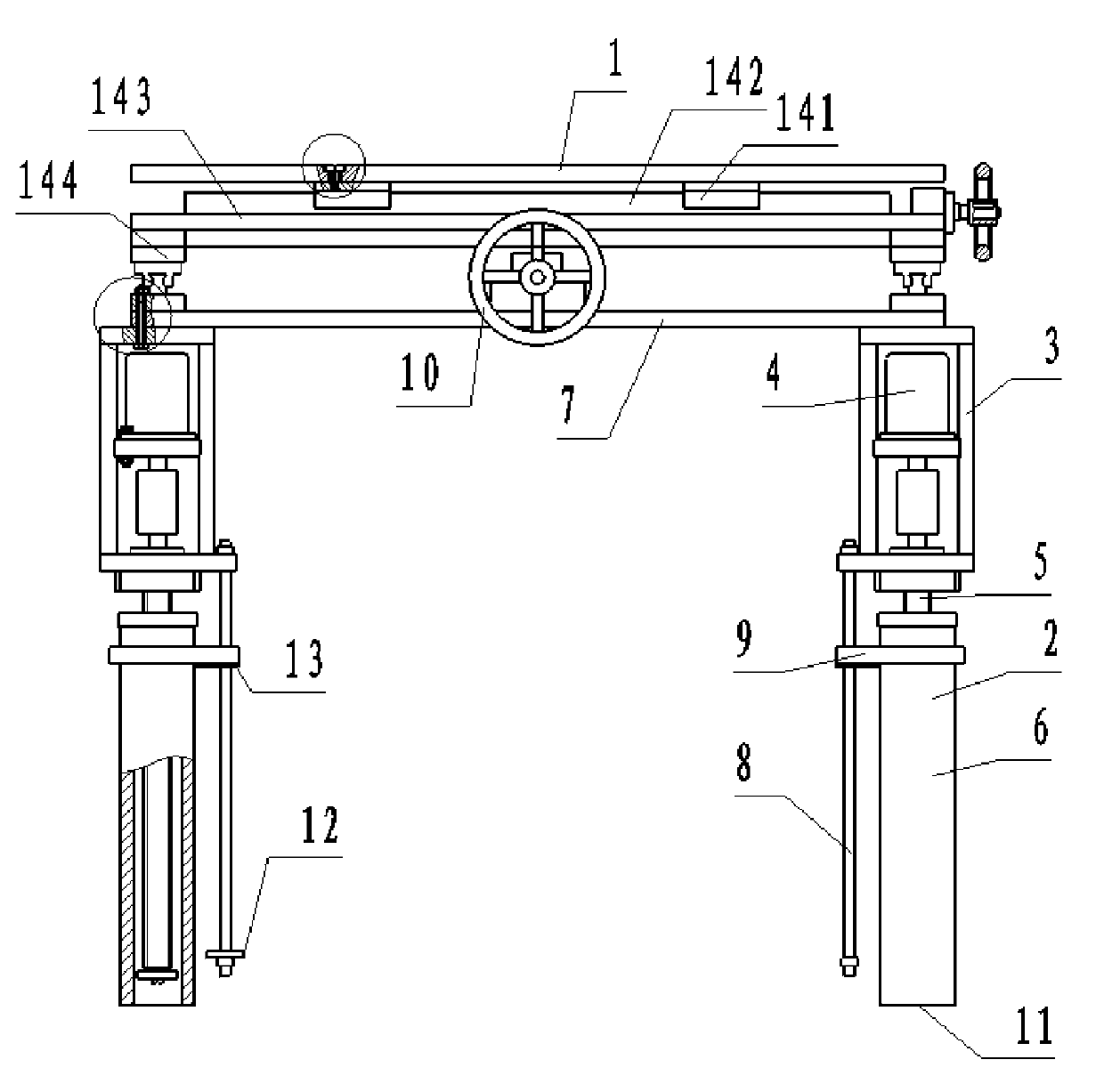

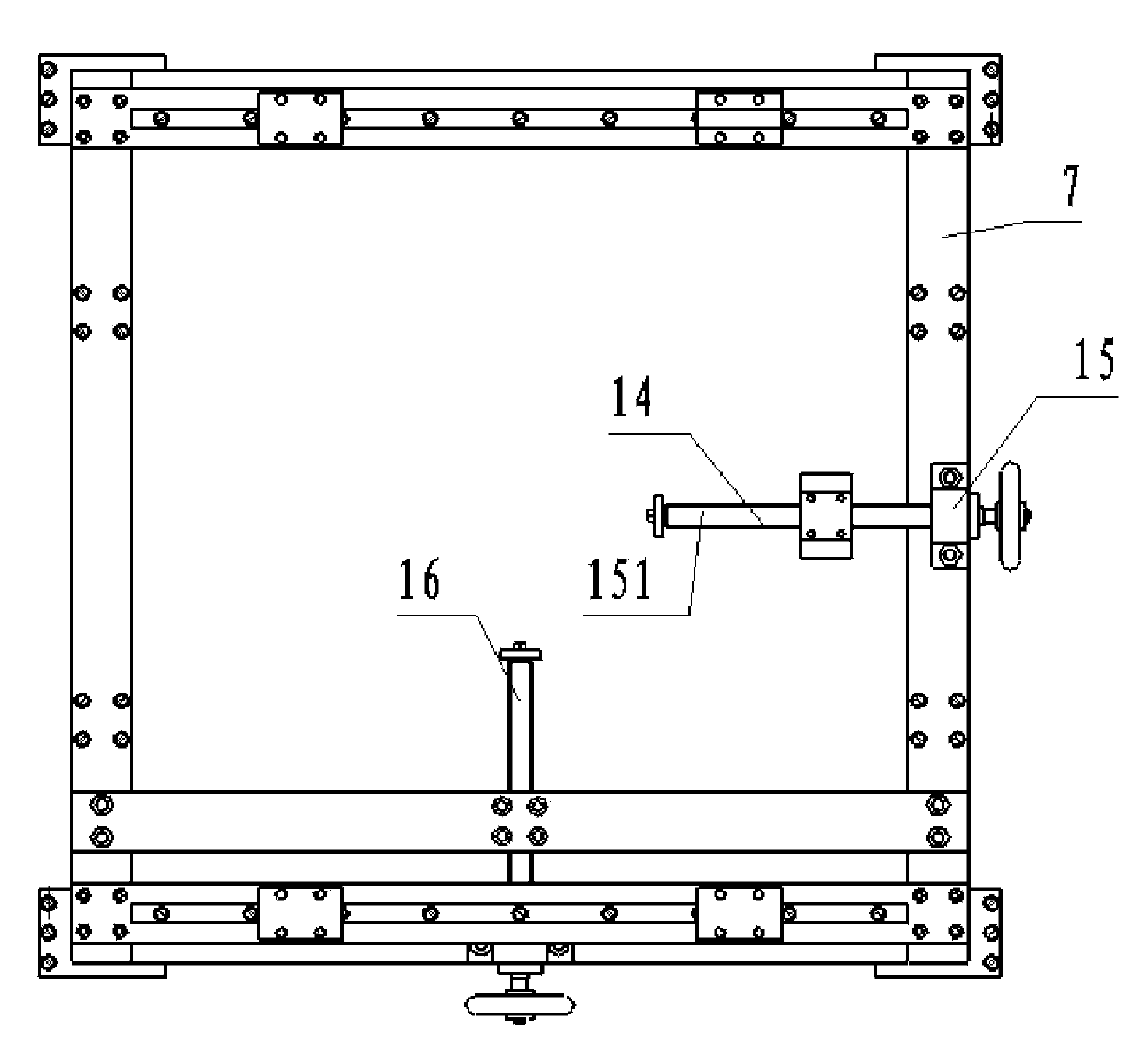

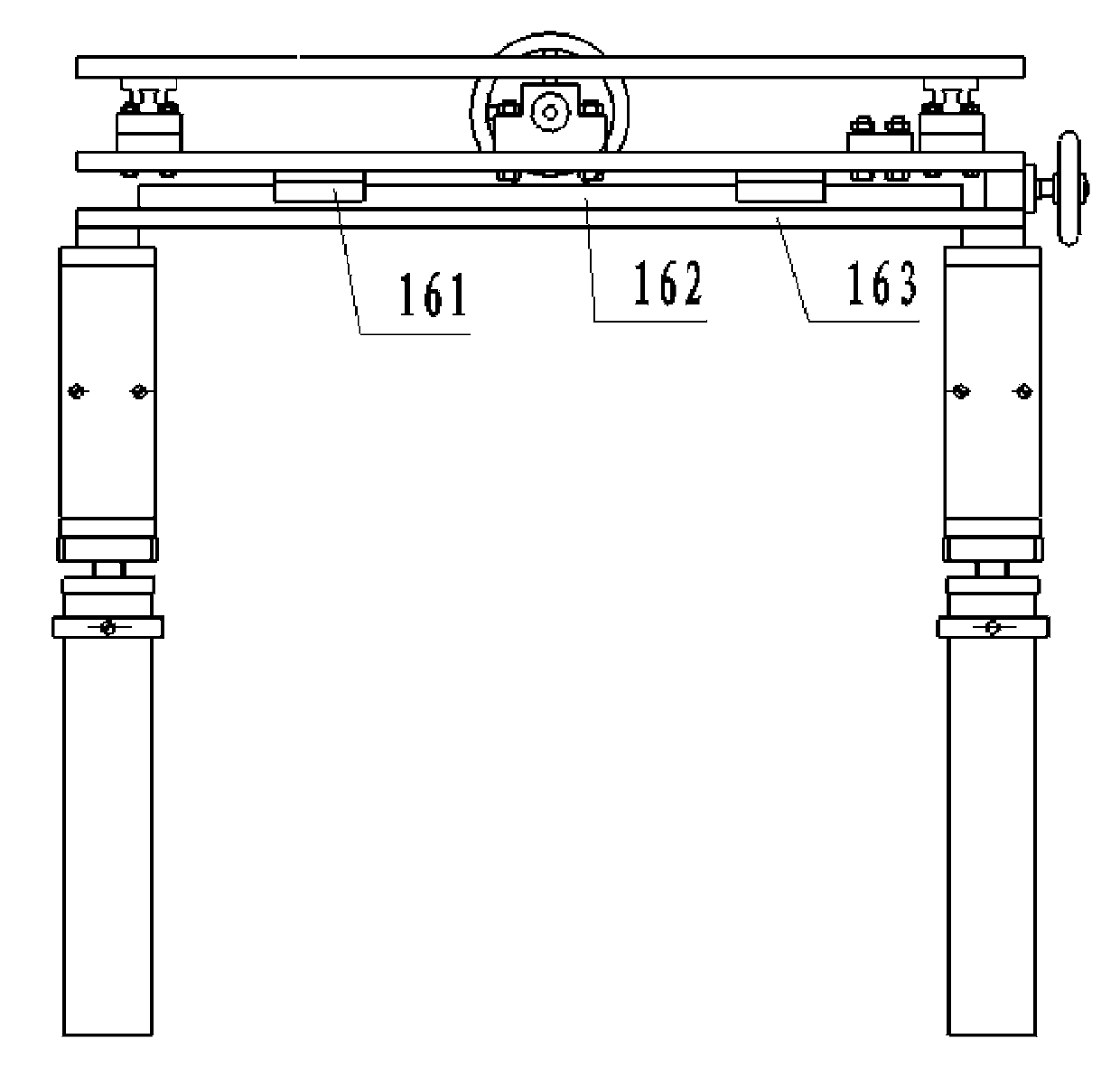

[0042] A leveling device for suspension equipment, including a panel 1 and four legs 2, the panel is supported on the four legs, and each leg includes a motor fixing box 3, a stepping motor 4, and a ball screw pair 5 , cylindrical support legs 6, the motor fixing box is fixed on the end of the bottom surface of the sliding screw seat fixing plate 7, the motor is arranged in the motor fixing box through the motor fixing bracket installed in the motor fixing box, and the ball screw pair The screw in the ball screw is connected with the main shaft of the motor through a coupling, and a screw pair is set in the inner cavity of the cylindrical leg. The screw in the ball screw pair goes out of the motor box and extends into the screw pair in the cylindrical leg. Among them, the support leg also includes a guide rod 8, the guide rod is parallel to the cylindrical support leg, and the upper end of the guide rod is connected to the motor box through the fixed frame fixed to the motor bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com