Automatic leveling device for suspension equipment

An automatic leveling and suspension technology, which is applied in the direction of mechanical equipment, engine frame, supporting machine, etc., can solve the problems of inability to accurately meet the installation accuracy of the mechanism box, easily damaged equipment components, and cumbersome installation procedures, etc., to improve the installation process Quality, save operating costs, save manpower and material resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

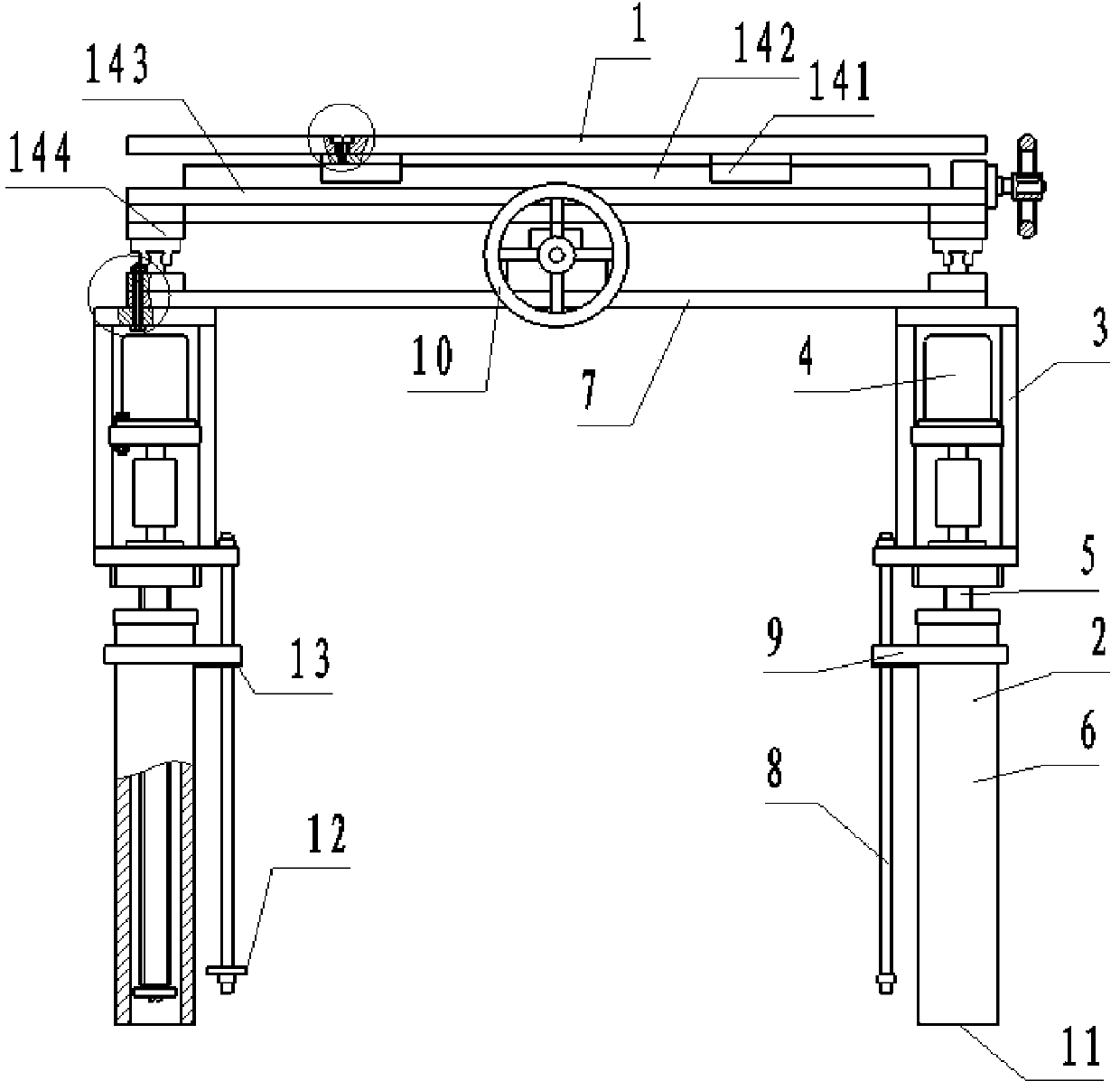

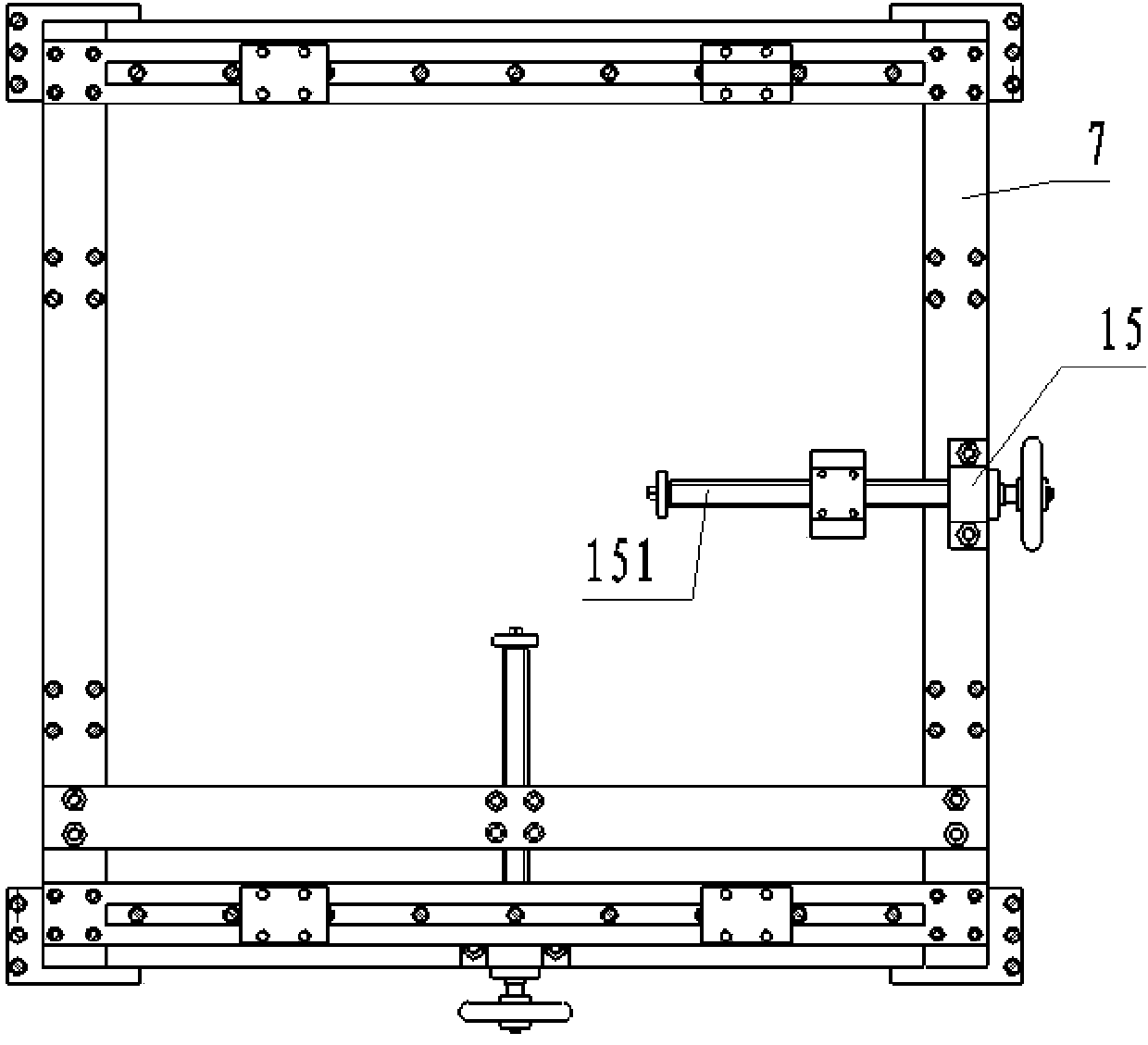

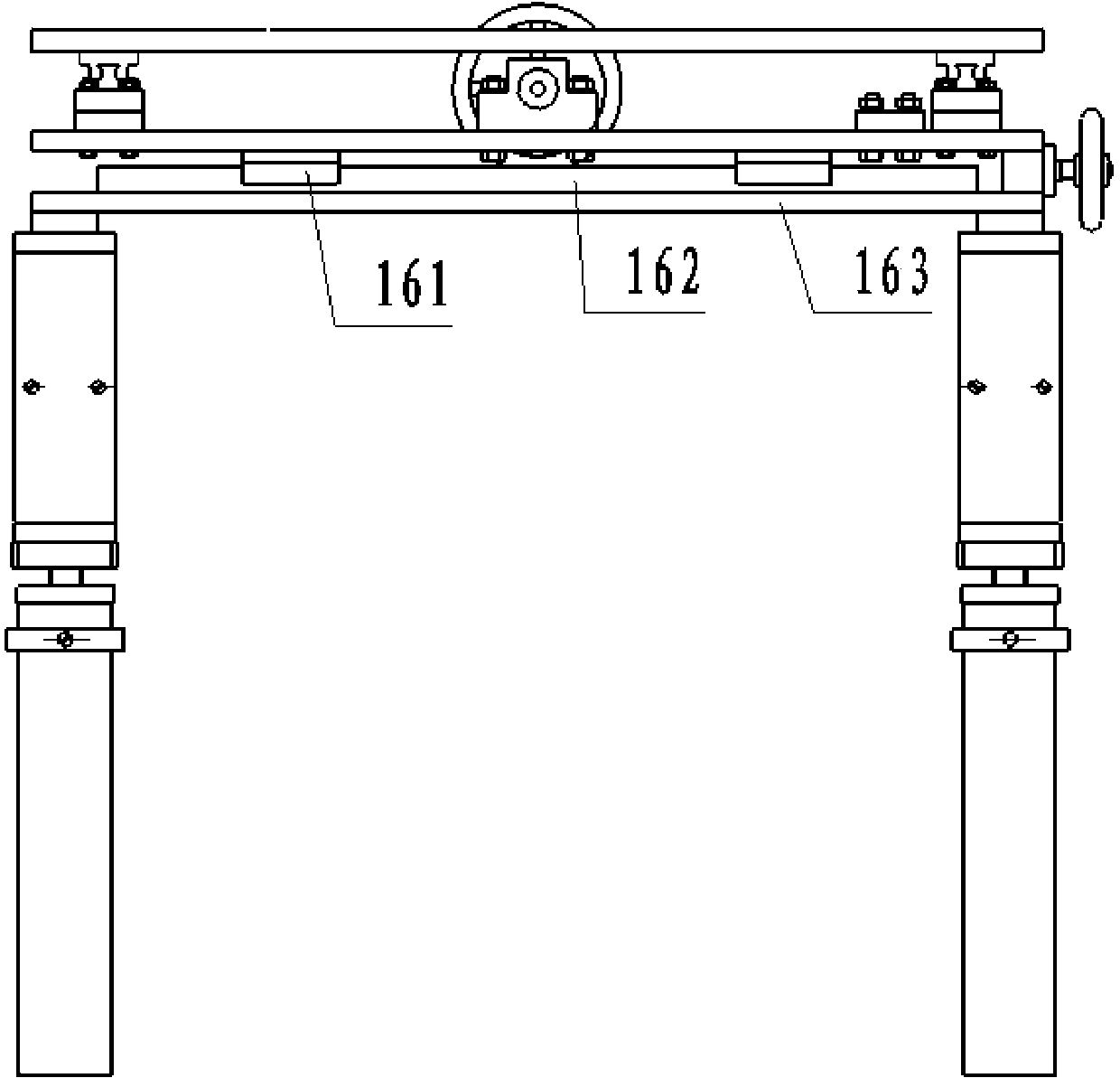

[0039]An automatic leveling device for suspended equipment, including a panel 1, and more than two first sliders 141 are arranged on the opposite sides of the bottom surface of the panel in the length direction, and the first sliders are arranged on two symmetrically arranged first sliders Moving on the block guide rail 142, the first slide block guide rail is installed on the first guide rail fixing frame 143, and two ends of the lower surface of the first guiding rail fixing frame are provided with two slides perpendicular to the first guiding rail fixing frame. The block holder 144 is provided with more than two second sliders 161 on the lower surface of the slider holder, and the second slider moves on the second slider guide rail 162, and the second slider guide rail Installed on the second guide rail fixing frame 163, the second rail fixing frame is installed on two sliding screw seat fixing plates perpendicular to it, and the middle position of the upper surface of the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com