Total oxygen kiln combustion control system

A control system and kiln technology, applied in the field of machinery, can solve problems such as inconvenient leak detection, large space occupation, and untimely closing speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

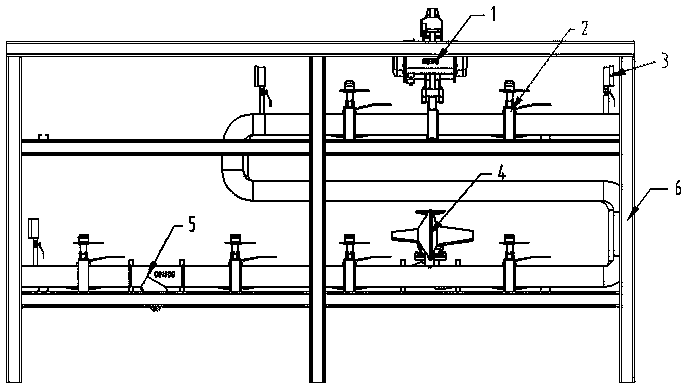

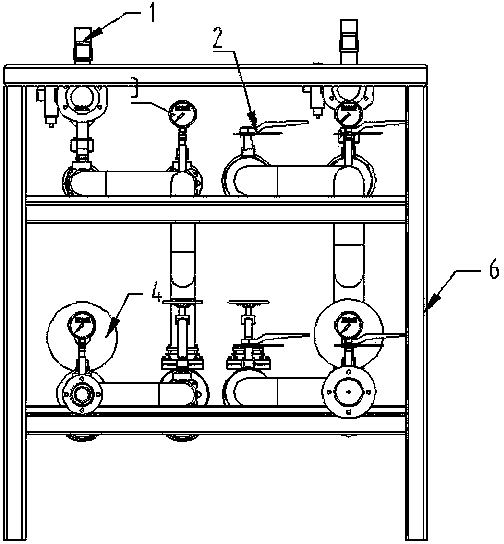

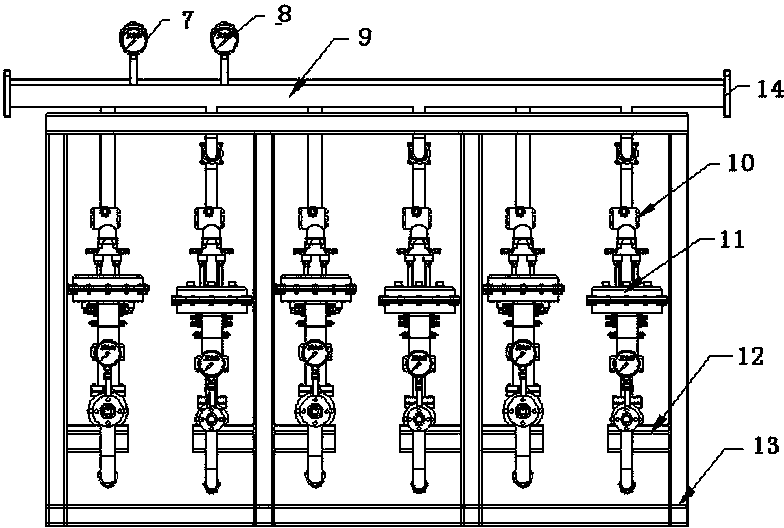

[0019] Such as figure 1 As shown, this integrated valve group includes a main valve group and a branch valve group, and the branch valve group includes an oxygen valve group and a natural gas valve group.

[0020] Main valve group: It is the valve group connected to the factory pipeline. The main valve group should be disconnected, and all branch valve groups should be disconnected. The main valve group integration of this system is to put two valve groups together in a fixed frame, and the outlet and inlet of the valve group have interfaces to facilitate the connection and connection of pipelines. Set safety shut-off valve 1 on the main valve group, safety shut-off valve 1 is set with bypass, bypass is equipped with manual butterfly valve 2, and safety shut-off valve 1 is stopped due to failure, and the gas supply can be restored immediately by opening the bypass. A pressure gauge 3 is set on the oxygen valve group and the natural gas valve group of the main valve group to f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com