Two-section high-temperature fluidized bed roasting furnace for waste casting sand

A high-temperature fluidized bed, two-stage technology, applied in the field of roasting furnaces, can solve the problems of not being able to adapt to the regeneration of mixed waste (core) sand thermal methods, and achieve the convenience of single-process layout, improve thermal efficiency, and occupy an area of equipment small area effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described below in conjunction with specific drawings.

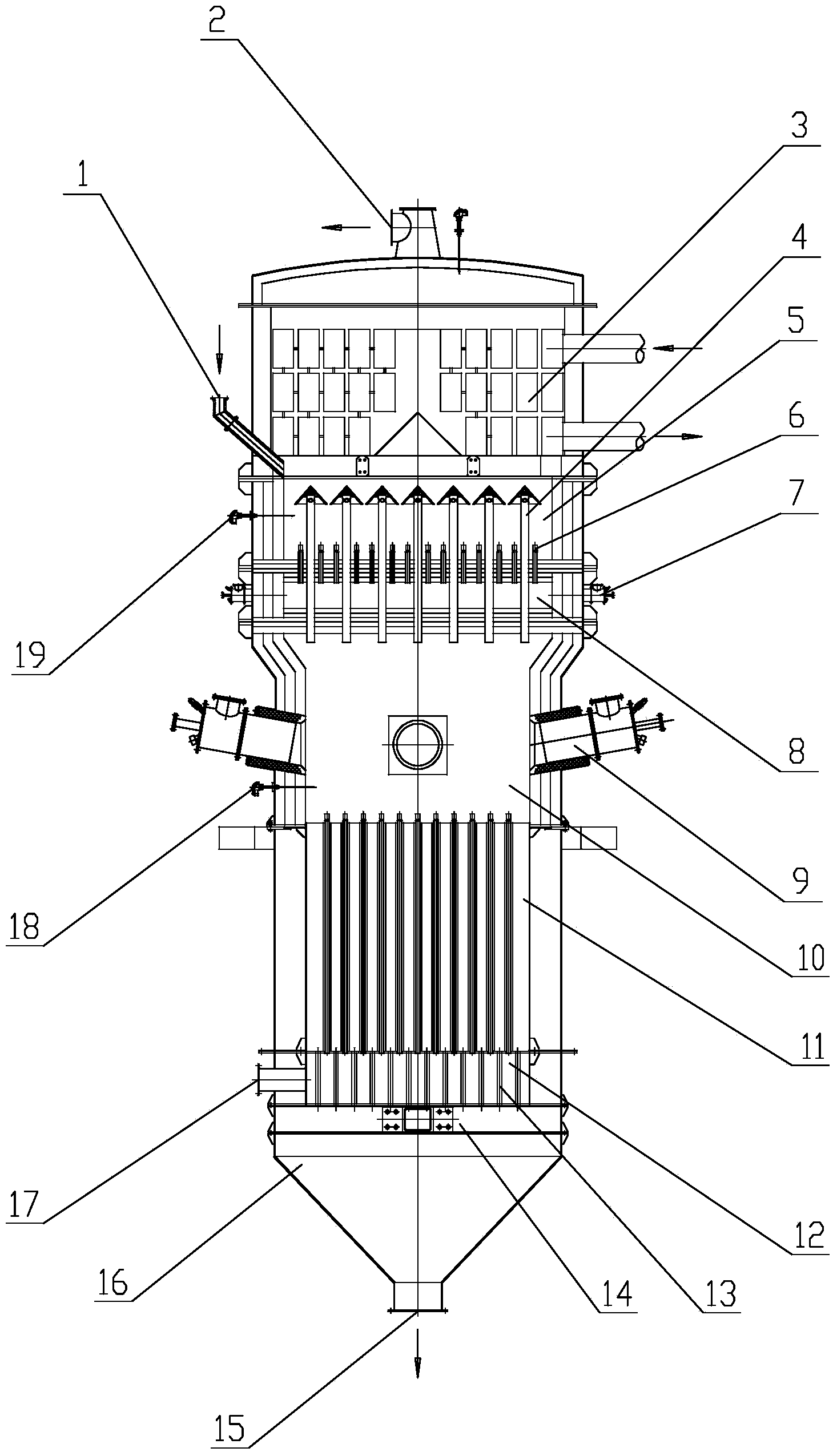

[0011] like figure 1 As shown: the waste sand two-stage high-temperature fluidized bed roasting furnace includes a sand inlet channel 1, a smoke exhaust channel 2, an air heat exchanger 3, a section of sand lower pipe 4, a section of fluidization chamber 5, a section of fluidization nozzle 6, One-stage high-pressure burner 7, one-stage high-pressure combustion chamber 8, second-stage burner 9, second-stage fluidization chamber 10, second-stage air preheating chamber 11, second-stage gas collection chamber 12, second-stage sand outlet pipe 13, sand outlet valve 14. Sand outlet 15, sand collecting bucket 16, fluidizing air inlet 17, second-stage temperature detector 18, first-stage temperature detector 19, etc.

[0012] like figure 1 As shown, the present invention includes a first-stage fluidization chamber 5, a first-stage high-pressure combustion chamber 8, a second-stage f...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap