Nut internal screw thread detection machine

A technology of nut internal thread and detection machine, which is applied in the direction of measuring devices, mechanical devices, mechanical measuring devices, etc., can solve the problems of increased production and purchase costs, increased volume of detection machines, increased labor intensity, etc., and achieve production and purchase costs. Low, simple structure, small size effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific preferred embodiments.

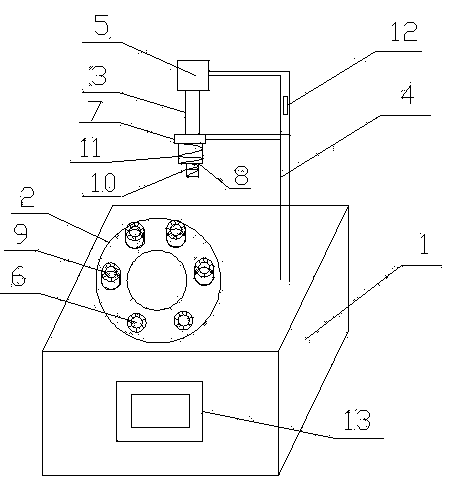

[0013] Such as figure 1 As shown, a nut internal thread detection machine includes a frame 1, a rotatable nut placement plate 2 arranged in the frame 1 and a retractable thread detection manipulator 4 above the frame 1, the thread detection manipulator 4 It includes a stepper motor 5 placed on the top, a torque sensor 3, a thread gauge fixture 7 connected with a thread gauge 8, and a displacement sensor 12 for detecting the displacement of the thread gauge 8; To place the through step hole 6 of the nut 9 to be measured; the thread gauge 8 includes a lower limit thread gauge 10 placed below and an upper limit thread gauge 11 placed above, wherein the lower limit thread gauge 10 can pass through the stepped hole 6 .

[0014] The height of the lower limit thread gauge 10 is preferably equal to the height of the nut 9 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com