Drug-loaded silica embolism microsphere and preparation method thereof

A technology of silica and embolization microspheres, applied in the fields of polymer materials and biomedical engineering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

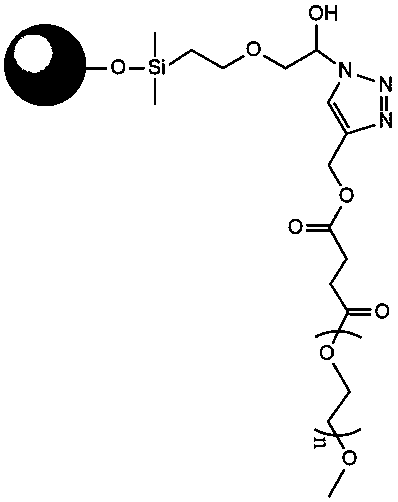

Image

Examples

Embodiment 1

[0027] (2) Add 10 grams of silica microspheres into 100 mL of toluene, ultrasonically disperse for 10 minutes, then add 4 grams of silane coupling agent KH-560, in a reactor equipped with a reflux condensation device, raise the temperature to 80°C, Stir and react for 12 hours, after centrifugation, wash with acetone and centrifuge three times, and vacuum dry at room temperature to obtain a white powder; add the white powder to 100mL solvent N,N-dimethylformamide, ultrasonically disperse evenly, add 2 g Sodium azide and 1.6 g of ammonium chloride were vigorously stirred at 50° C. for 40 hours; washed with a large amount of water and filtered to remove inorganic salts, and then vacuum-dried to obtain 9.8 g of azide-modified silica microspheres.

[0028] (3) Take 2 grams of polyethylene glycol containing alkyne terminal prepared in step (1) and dissolve it in 80 mL of water / n-butanol mixed solvent, add the azide-modified silica prepared in step (2) 9.8 grams of microspheres, disp...

Embodiment 2

[0033] (2) Add 8 grams of silica microspheres into 80 mL of toluene, ultrasonically disperse for 10 minutes, then add 3 grams of silane coupling agent KH-560, in a reactor equipped with a reflux condensing device, raise the temperature to 110 ° C at a constant speed Stir and react for 9 hours, after centrifugation, wash with acetone and centrifuge 3 times, dry under vacuum at room temperature to obtain a white powder; add the white powder to 80mL solvent N,N-dimethylformamide, ultrasonically disperse evenly, add 1.6g Sodium azide and 1.4 g of ammonium chloride were vigorously stirred at 50° C. for 35 hours; washed with a large amount of water and filtered to remove inorganic salts, and dried in vacuum after filtration to obtain 7.8 g of azide-modified silica microspheres.

[0034](3) Take 5 grams of polyethylene glycol containing alkyne terminal prepared in step (1) and dissolve it in 100 mL of water / n-butanol mixed solvent, add the azide-modified silica prepared in step (2) 7...

Embodiment 3

[0039] (2) Add 30 grams of silica microspheres to 250 mL of toluene, ultrasonically disperse for 10 minutes, then add 8 grams of silane coupling agent KH-560, in a reactor equipped with a reflux condensation device, raise the temperature to 100 ° C, uniform Stir the reaction for 10 hours, after centrifugation, wash with acetone and centrifuge three times, and vacuum dry at room temperature to obtain a white powder; add the white powder to 250mL solvent N,N-dimethylformamide, ultrasonically disperse evenly, add 4 g Sodium azide and 3.2 grams of ammonium chloride were vigorously stirred at 50° C. for 48 hours; washed with a large amount of water and filtered to remove inorganic salts, and dried in vacuum after filtration to obtain 28.2 grams of azide-modified silica microspheres.

[0040] (3) Take 5 grams of polyethylene glycol containing alkyne terminal prepared in step (1) and dissolve it in 300 mL of water / n-butanol mixed solvent, add the azide-modified silica prepared in step...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| number average molecular weight | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com