Novel piezoelectric valveless micromixer

A micro-mixer and piezoelectric technology, applied in the field of micro-mechanics, can solve the problems of high energy consumption, low liquid flow rate and Reynolds number, large ratio of fluid surface area to volume, etc., achieving low power consumption, simple structure, The effect of simple flow resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

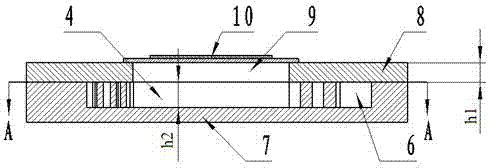

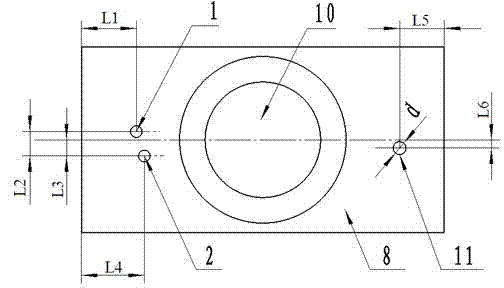

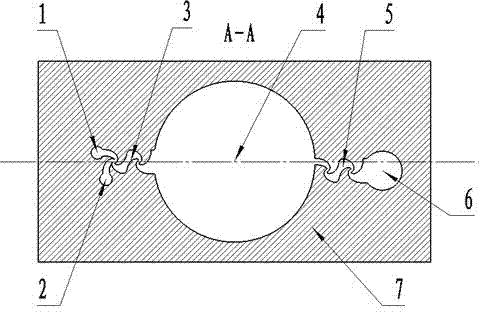

[0014] Such as Figure 1~3 As shown, the present invention includes pump inlet one 1, pump inlet two 2, inlet mixing unit 3, pump body pump chamber 4, outlet mixing unit 5, outlet buffer chamber 6, pump body 7, upper base body 8, base body pump chamber 9, The piezoelectric vibrator 10 and the pump outlet 11. The pump body 7 and the upper base body 8 are bonded together up and down. The upper base body 8 is provided with a pump inlet 1, a pump inlet 2, a pump outlet 11 and a base pump chamber 9. The pump body 7 is provided with a pump inlet mixing unit 3 , pump body pump chamber 4, outlet mixing unit 5, outlet buffer chamber 6. The piezoelectric vibrator 10 is made by bonding piezoelectric ceramics to an elastic substrate, and is fixed directly above the pump cavity 9 of the substrate by an adhesive. On the upper substrate 8, the pump inlet 1 and the pump inlet 2 communicate with the inlet mixing unit 3, the inlet mixing unit 3 communicates with the pump cavity 4, the pump ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com