Self-driven digital micro-chute based on friction generator

A technology of triboelectric generator and digital microflow, which is applied in laboratory containers, laboratory utensils, chemical instruments and methods, etc., can solve the problems of high cost, unsuitable for large-scale production, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

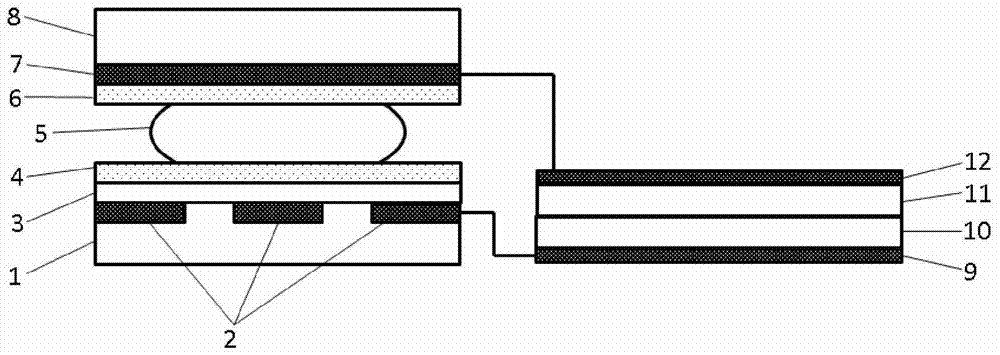

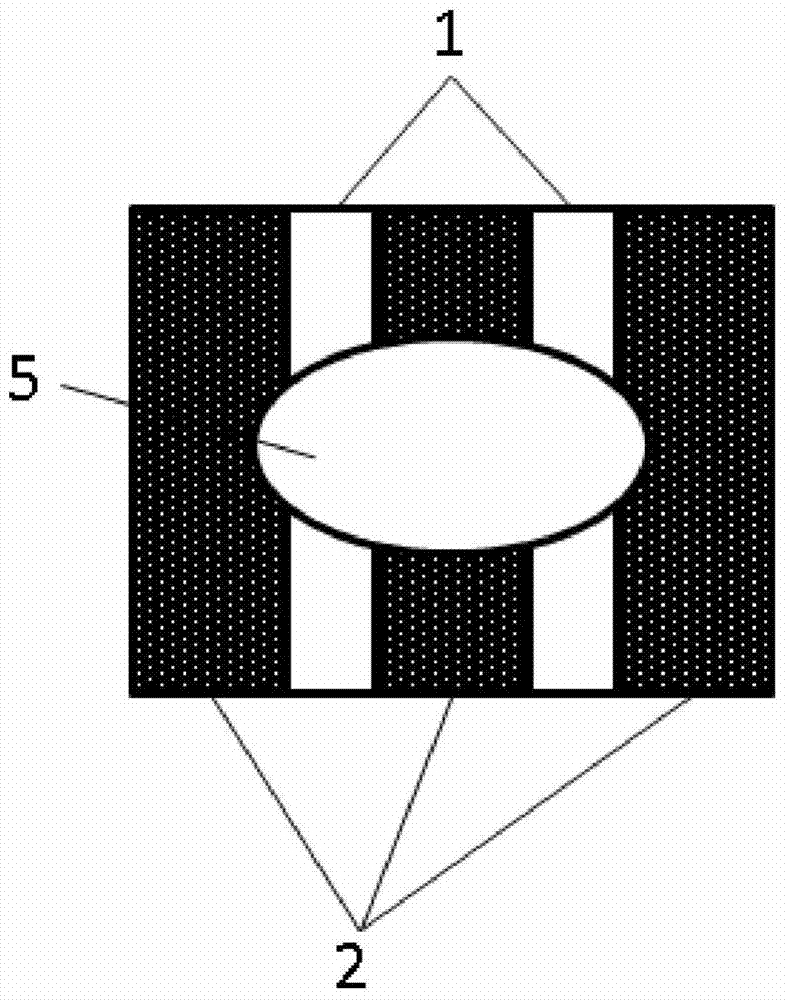

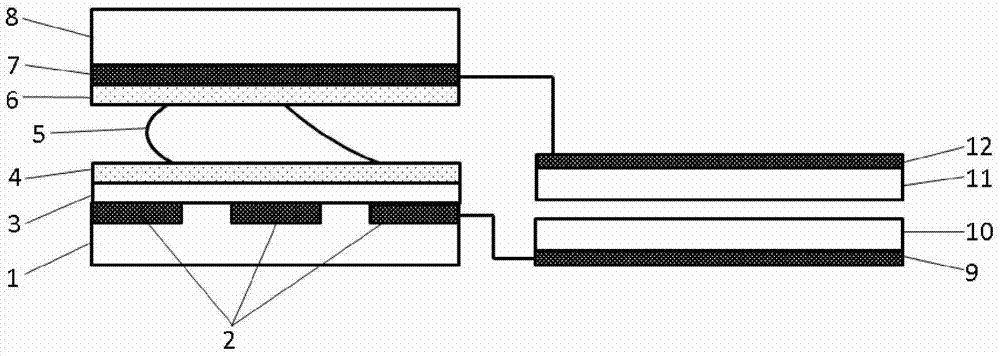

[0025] like Figure 1 to Figure 2 As shown, the self-driven digital microchannel based on the friction generator of the present invention is composed of a digital microchannel and a friction generator, wherein the digital microchannel part is composed of a lower support material 1, a lower driving electrode 2, a dielectric layer 3, The lower hydrophobic layer 4, the droplet 5, the upper hydrophobic layer 6, the upper driving electrode 7, and the upper support material 8; the friction generator part is composed of the lower friction electrode 9, the lower friction material 10, the upper friction material 11, and the upper friction electrode 12 . Among them, the droplet 5 is located between the upper hydrophobic layer 6 and the lower hydrophobic layer 4, the dielectric layer 3, the lower driving electrode 2 and the lower support material 1 are located below the lower hydrophobic layer 4, and the upper driving electrode 7 is sequentially above the upper hydrophobic layer 6. And ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com