Processing system and method for compatible processing of natural material gravel and artificial hard rock and gravel

A processing system, sand and gravel technology, applied in the direction of grain processing, etc., can solve the problems of high cost and achieve the effect of saving floor space, reducing land occupation, and reducing the amount of construction and installation works

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

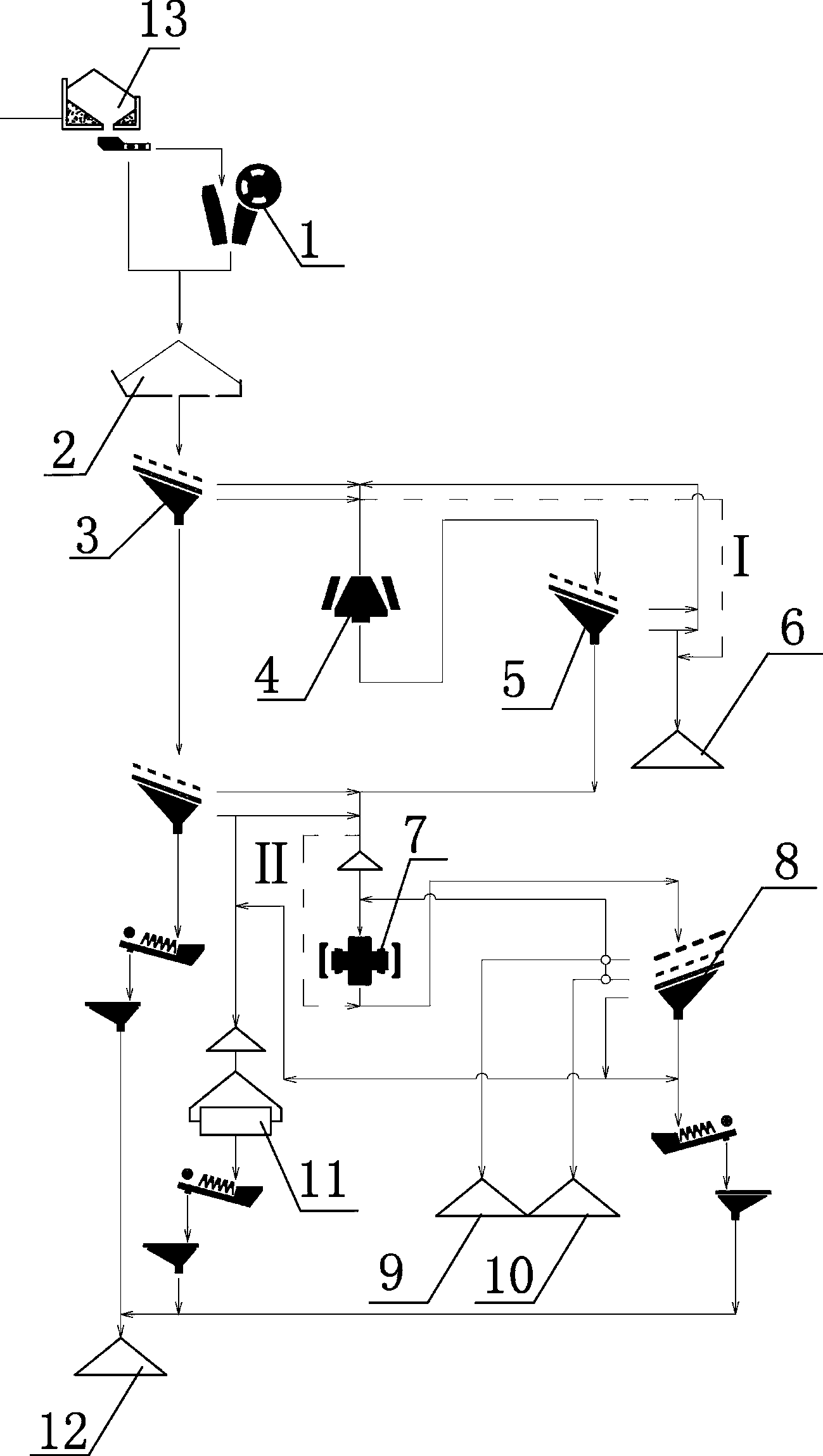

[0021] The hard rock sand and gravel system of the present invention is also suitable for natural material processing systems, and integrates two independent single-source sand and gravel systems, the onshore natural material sand and gravel system and the artificial hard rock sand and gravel system. To achieve a unified process flow, a unified selection of crushing equipment and screening equipment, and a unified sand making process. Taking the production of the three-stage sand and gravel system as an example, it illustrates different production periods and aggregate processing suitable for different sources.

[0022] The device structure of the present invention is as figure 1 Shown: a processing system compatible with natural sandstone and artificial hard rock sandstone, including a silo 13, a coarse crushing device 1 is arranged below the silo 13, and the coarse crushing device 1 cooperates with the first screening device 3 After the first screening device 3, a medium fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com