Preparation process of ram-type spectacle case

A preparation process and technology for glasses cases, applied in accessories, clothing, applications, etc., can solve the problems of short service life, insufficient strength, easy damage, etc., and achieve the effect of long service life, short process and good structural strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

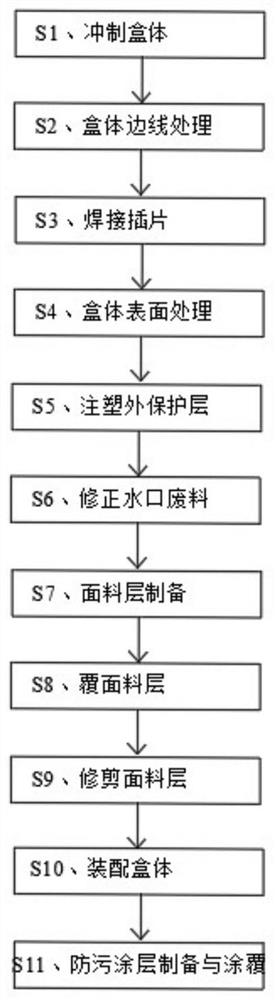

[0032] refer to figure 1 , a kind of preparation technology of stamping type spectacle case, comprises the following steps:

[0033] S1. Punching the box body: Stamping and stretching the box body with a drawing die, the box body includes an upper part and a lower part, and punching holes on one side of the lower part with a side punching die;

[0034] S2. Box edge processing: deburring the punching edge of the box;

[0035] S3. Welding insert: Weld an elastic card that matches the punching hole in the lower part on one side of the upper part:

[0036] S4, surface treatment of the box body: surface treatment is performed on the surface of the box body;

[0037] S5. Injection molding outer protective layer: place the box body in an injection mold, and coat and inject a layer of resin material on the surface of the box body;

[0038] S6. Correcting nozzle waste: remove the waste at the injection nozzle;

[0039] S7, fabric layer preparation: prepare the fabric layer for cove...

Embodiment 2

[0054] refer to figure 1 , a kind of preparation technology of stamping type spectacle case, comprises the following steps:

[0055] S1. Punching the box body: Stamping and stretching the box body with a drawing die, the box body includes an upper part and a lower part, and punching holes on one side of the lower part with a side punching die;

[0056] S2. Box edge processing: deburring the punching edge of the box;

[0057] S3. Welding insert: Weld an elastic card that matches the punching hole in the lower part on one side of the upper part:

[0058] S4, surface treatment of the box body: surface treatment is performed on the surface of the box body;

[0059] S5. Injection molding outer protective layer: place the box body in an injection mold, and coat and inject a layer of resin material on the surface of the box body;

[0060] S6. Correcting nozzle waste: remove the waste at the injection nozzle;

[0061] S7, fabric layer preparation: prepare the fabric layer for cove...

Embodiment 3

[0075] refer to figure 1 , a kind of preparation technology of stamping type spectacle case, comprises the following steps:

[0076] S1. Punching the box body: Stamping and stretching the box body with a drawing die, the box body includes an upper part and a lower part, and punching holes on one side of the lower part with a side punching die;

[0077] S2. Box edge processing: deburring the punching edge of the box;

[0078] S3. Welding insert: Weld an elastic card that matches the punching hole in the lower part on one side of the upper part:

[0079] S4, surface treatment of the box body: surface treatment is performed on the surface of the box body;

[0080] S5. Injection molding outer protective layer: place the box body in an injection mold, and coat and inject a layer of resin material on the surface of the box body;

[0081] S6. Correcting nozzle waste: remove the waste at the injection nozzle;

[0082] S7, fabric layer preparation: prepare the fabric layer for cove...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com