Patents

Literature

35results about How to "Process layout is reasonable" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

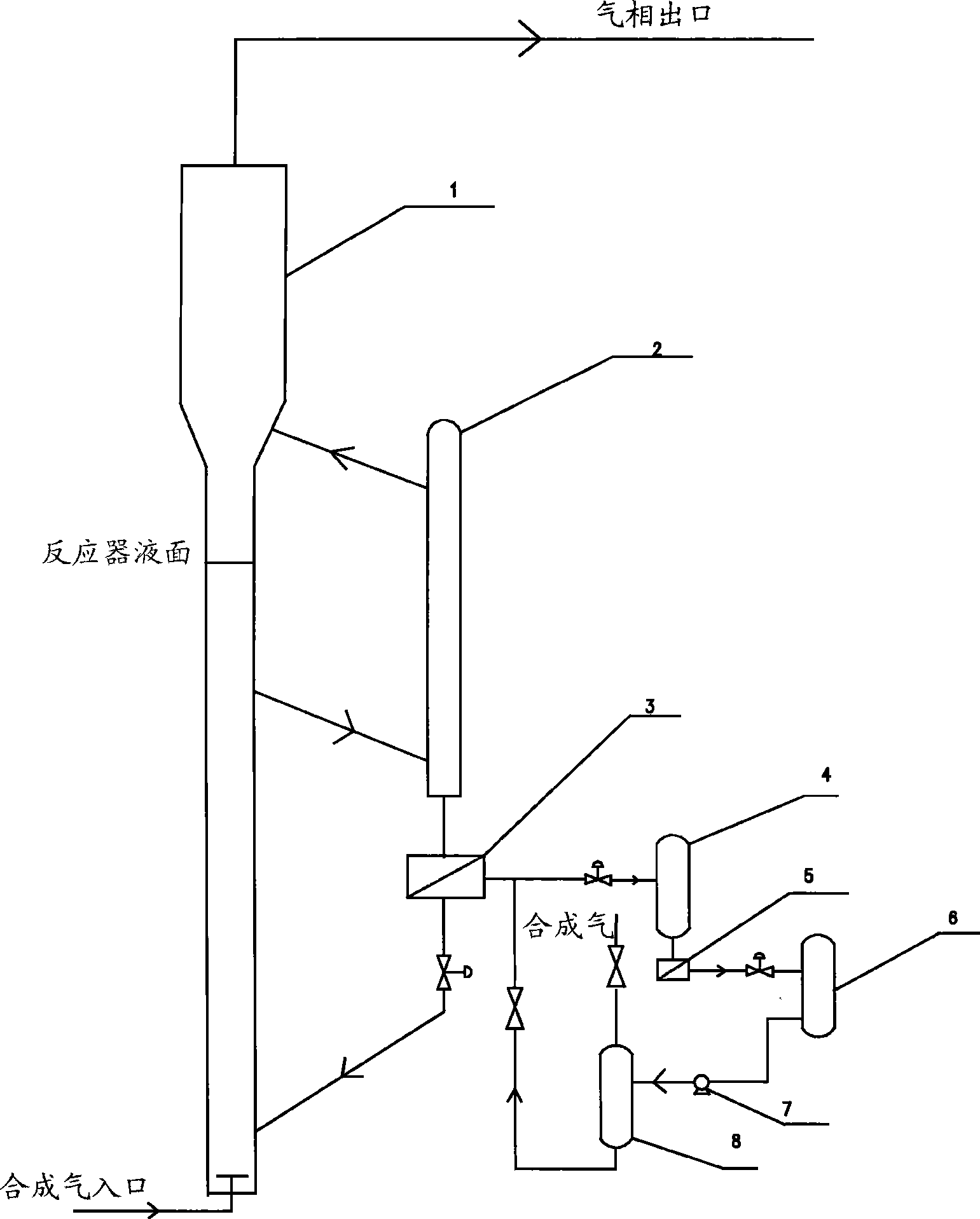

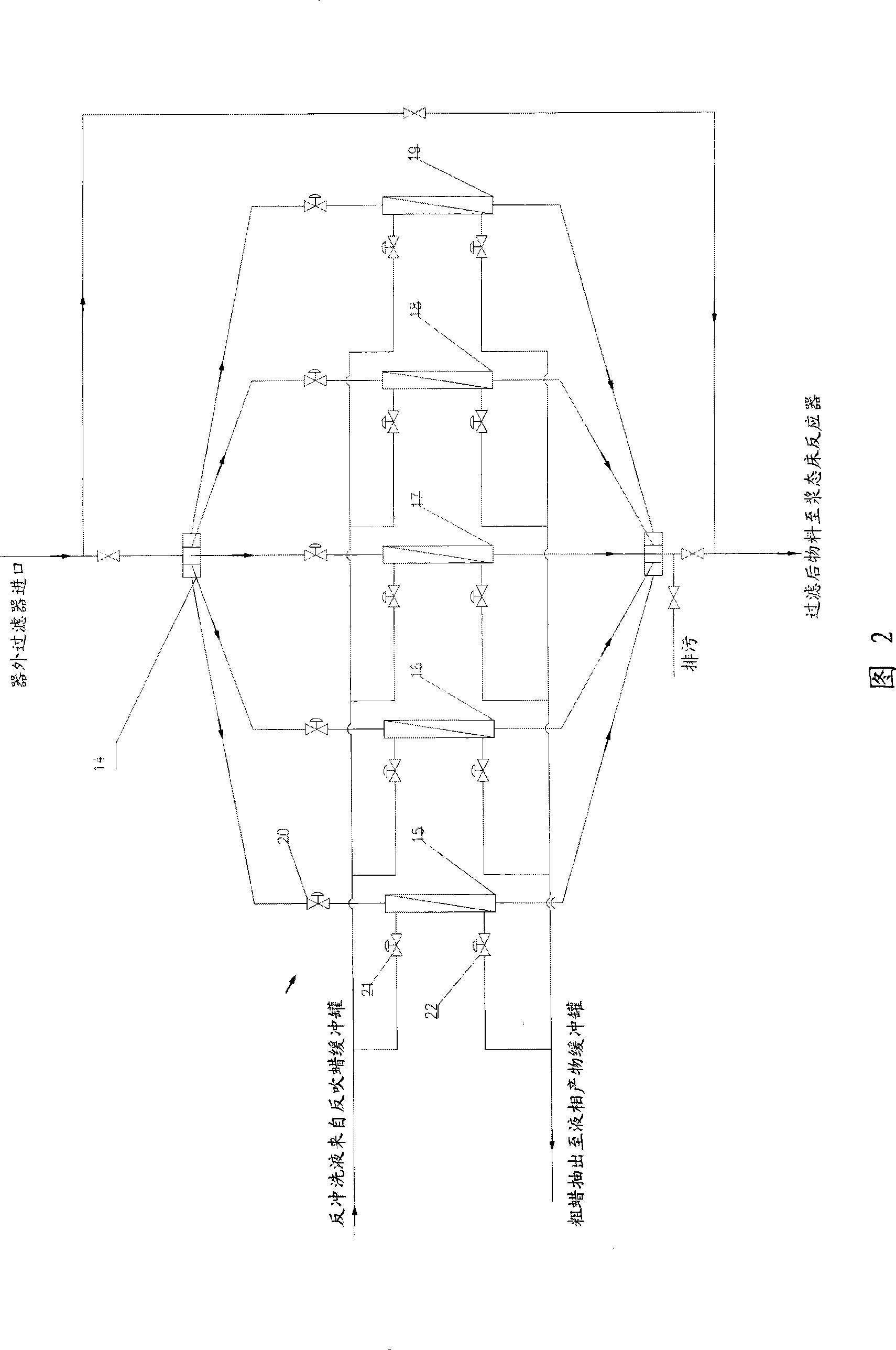

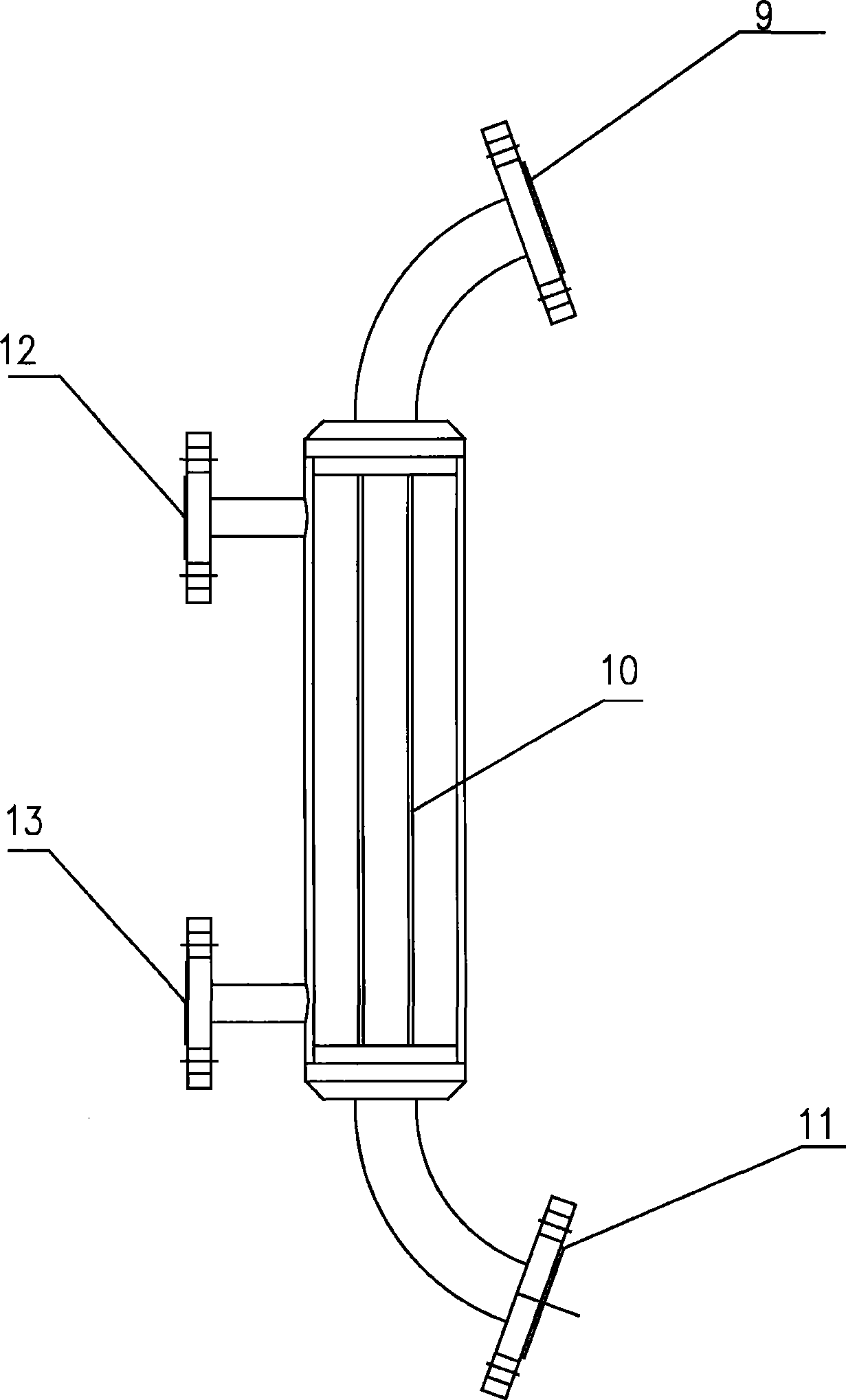

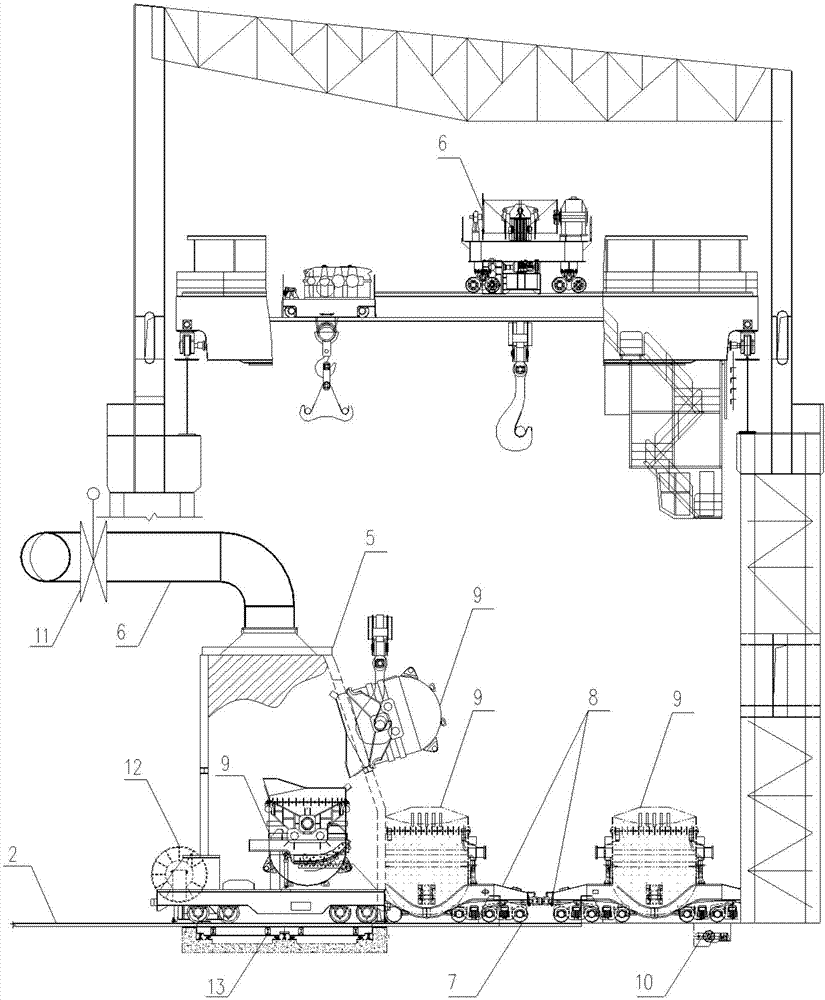

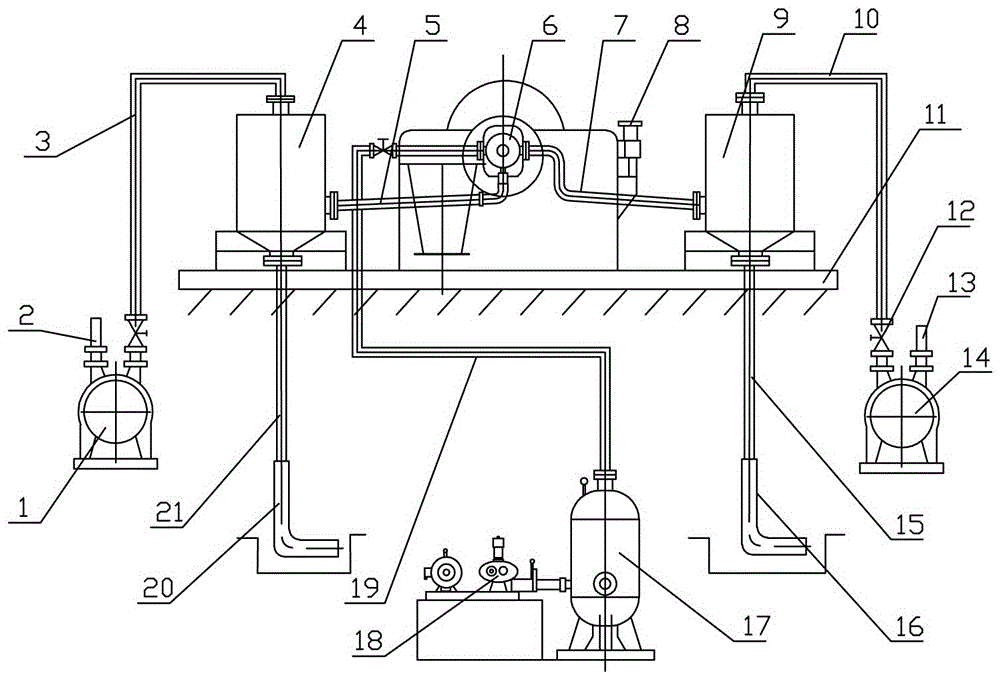

Wax extraction automatic filter, backwashing system of Ft synthetic pulp bed reactor

ActiveCN101417219AAvoid damageReduce the pressure on fine filtrationHydrocarbon from carbon oxidesLiquid hydrocarbon mixture productionWaxSlurry reactor

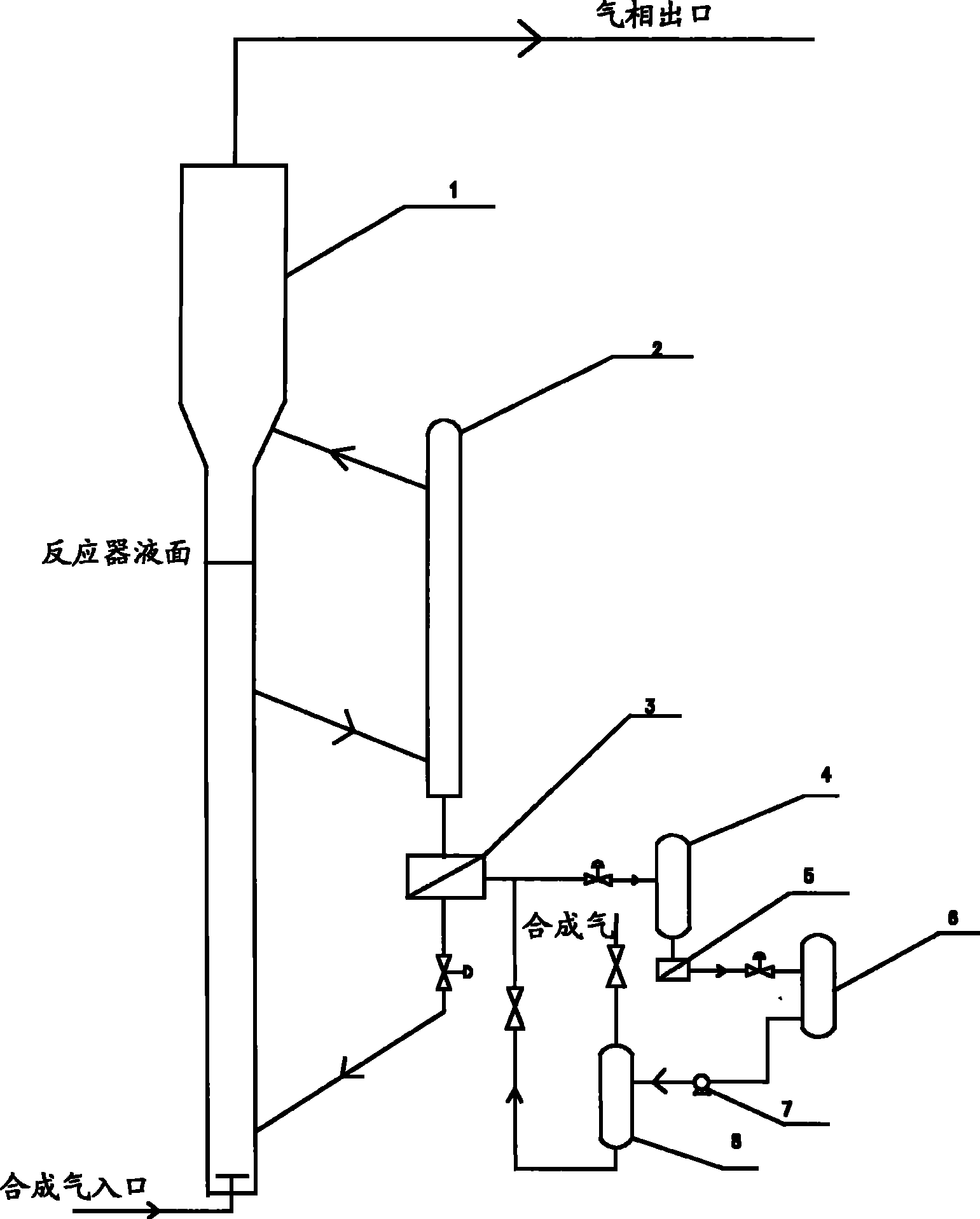

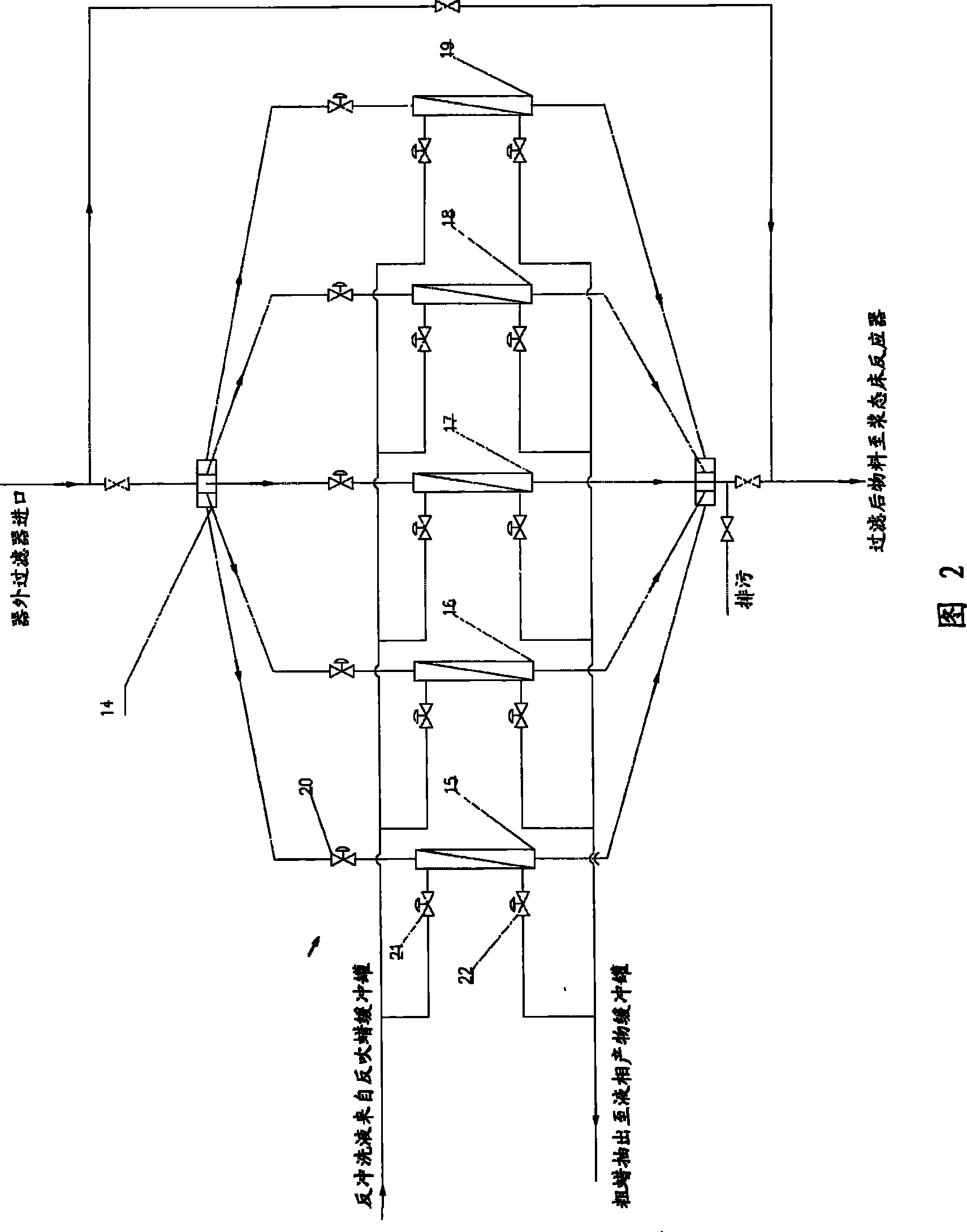

The invention discloses a wax extraction automatic filtration and backwashing system used for Fischer-Tropsch synthesis slurry reactor, comprising a filter unit and a backwashing unit, wherein, the filter unit comprises a slurry buffer tank, a wax device external filter (30), a coarse wave outcome buffer tank (4), a wax fine filter (5) and a wax product buffer tank (6); and the backwashing system comprises a washing wax pump (7) and a backwashing wax buffer tank (8). The wax extraction automatic filtration and backwashing system has the advantages of reasonable structure, short flow, low energy dissipation, avoiding the blocking or reverse flowing, reducing the damage of catalyst grains, and achieving the stable and continuous running of the Fischer-Tropsch synthesis slurry reactor.

Owner:CHNA ENERGY INVESTMENT CORP LTD +1

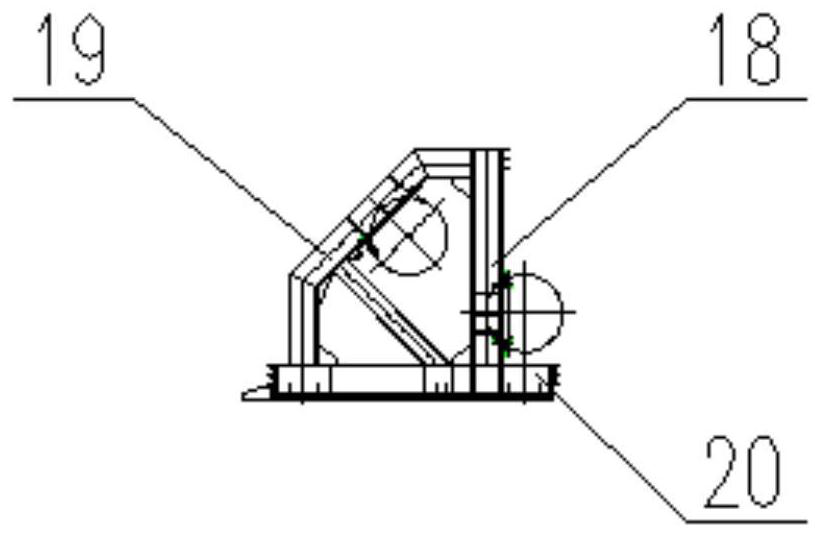

Cigarette automatic sorting process

InactiveCN1803559AFlexible configurationMeet the requirements of the orderArticle unpackingConveyor partsEngineeringTransmission equipment

The invention discloses a bar-cigarette self-picking craft, which is characterized by the following: opening the cigarette box automatically; fetching cigarette pile from box; feeding material automatically through over two picking equipments; picking different kinds of bar-cigarette on respective transmission equipment according to the need of order. The invention can improve material-supplement and picking efficiency and system disposal ability, which reduces the labor strength.

Owner:YUNNAN KUNMING SHIPBUILDING DESIGN & RESEARCH INSTITUTE

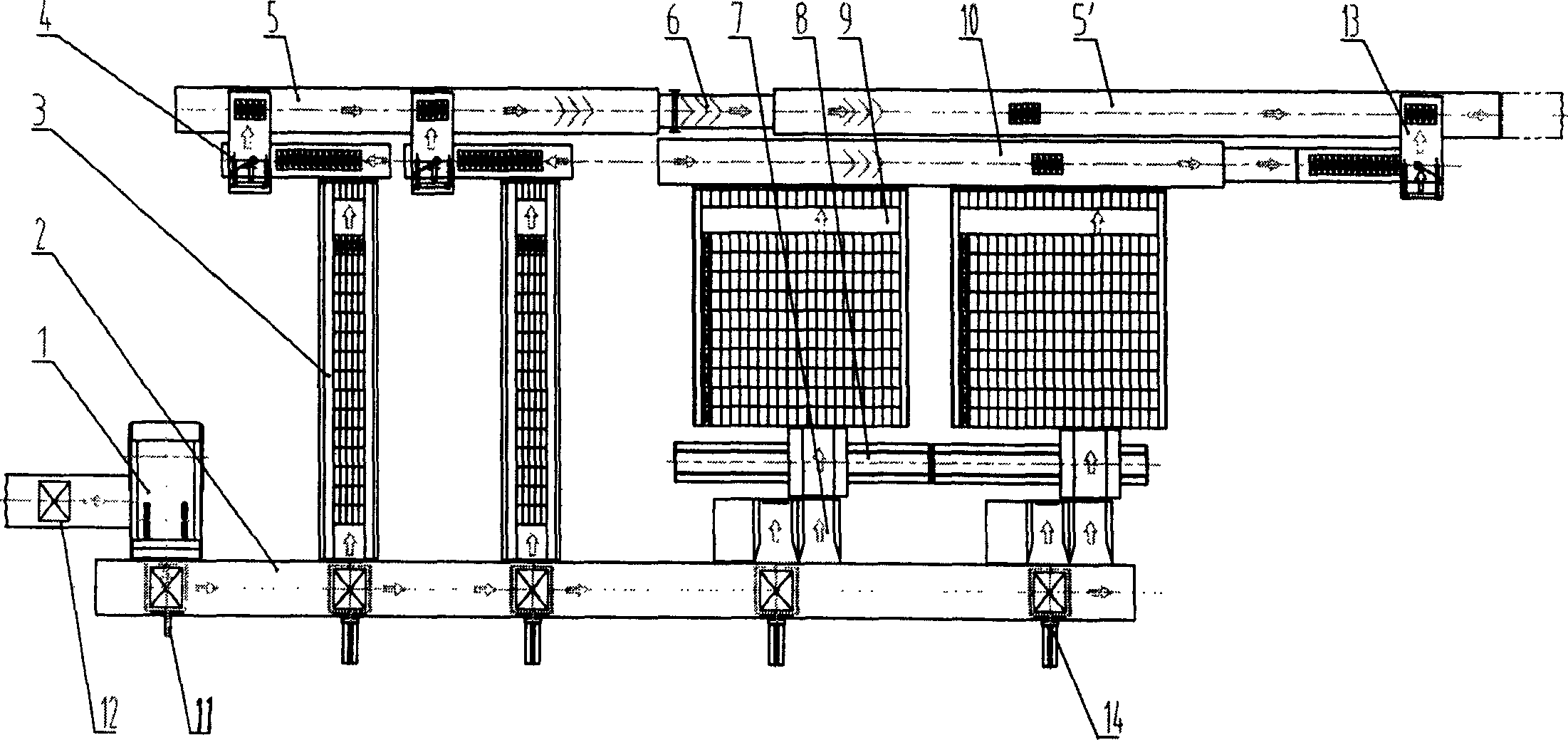

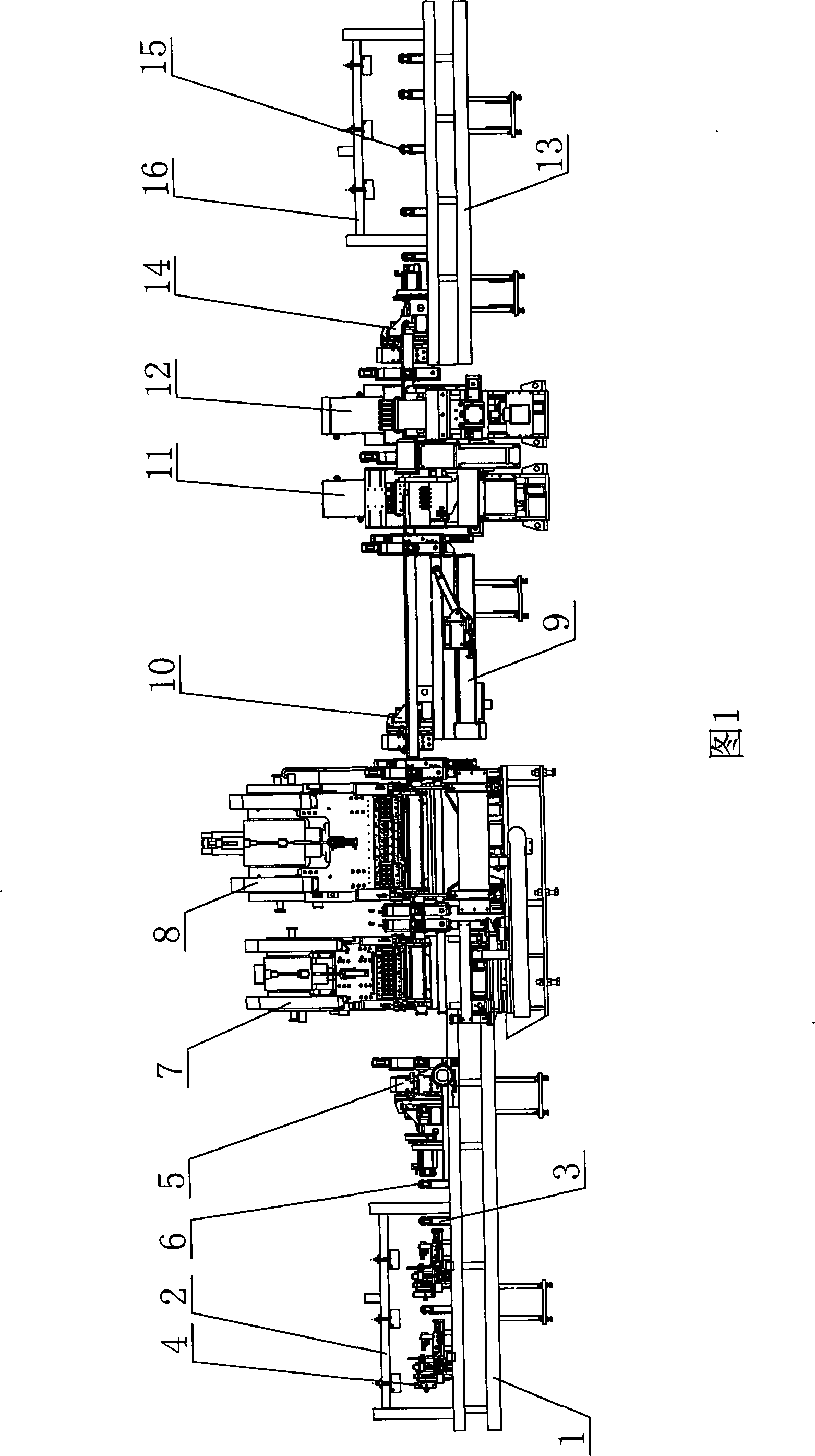

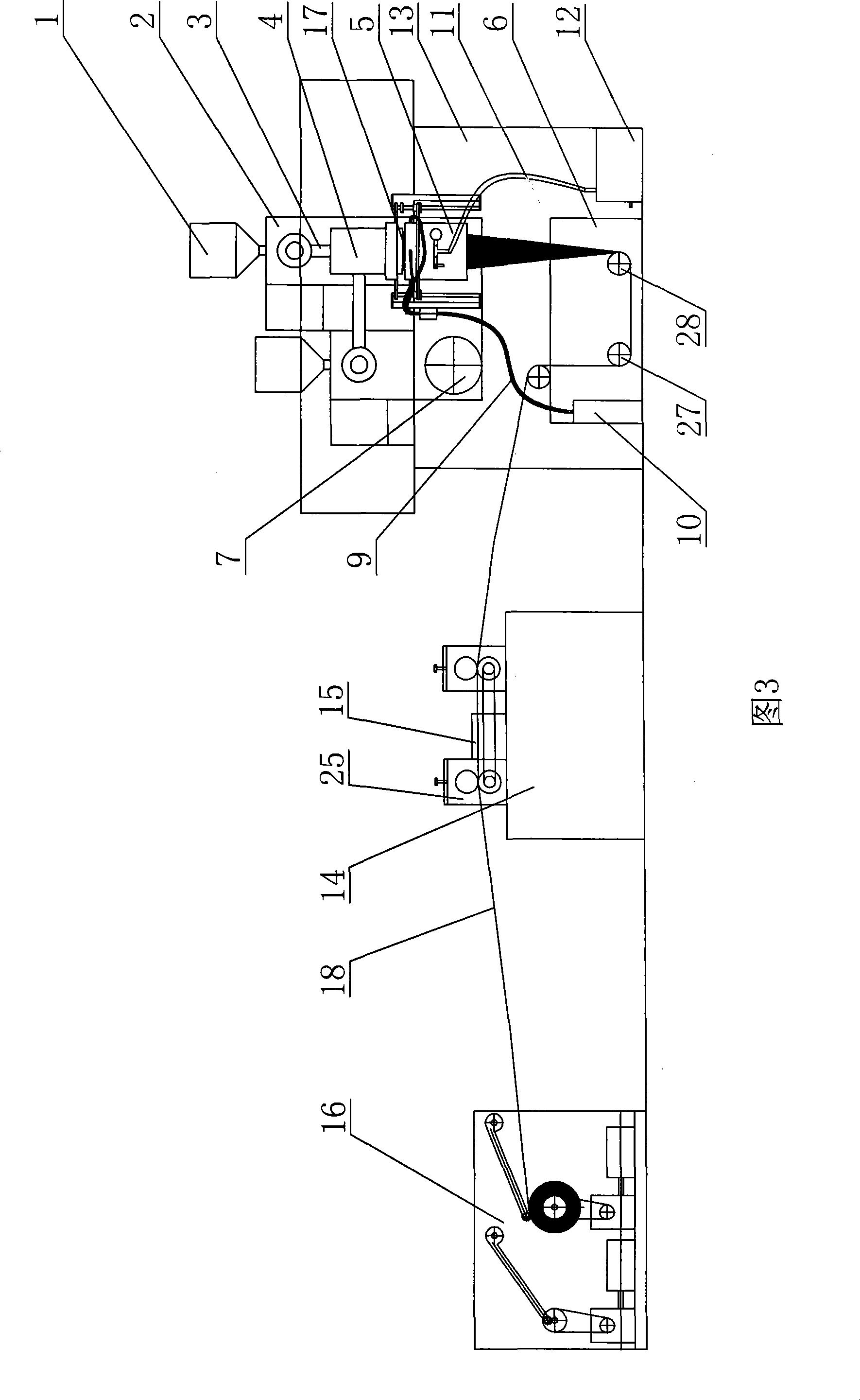

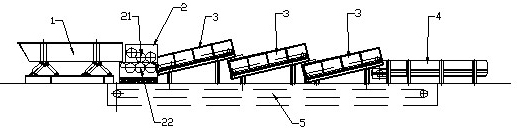

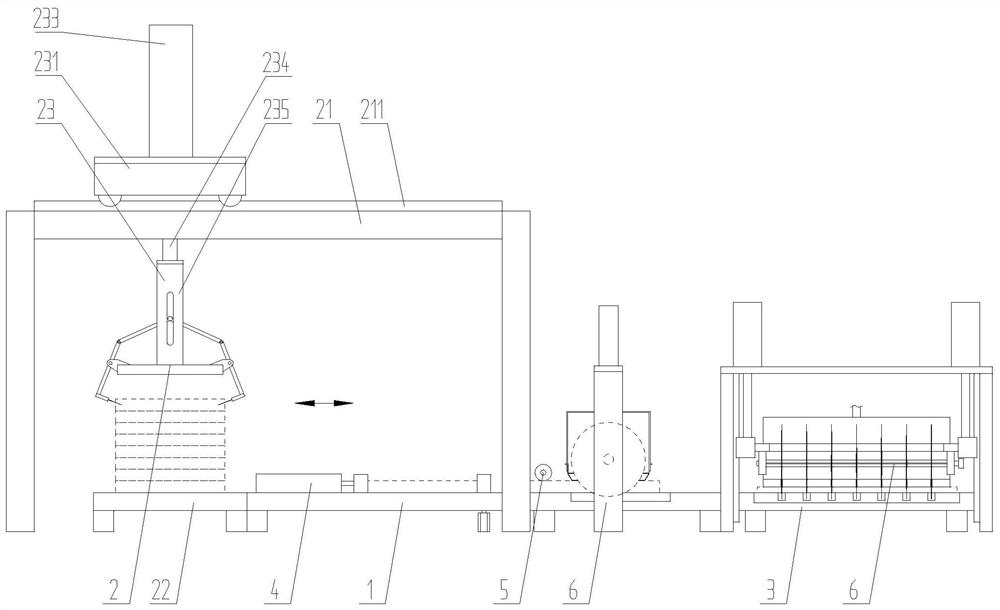

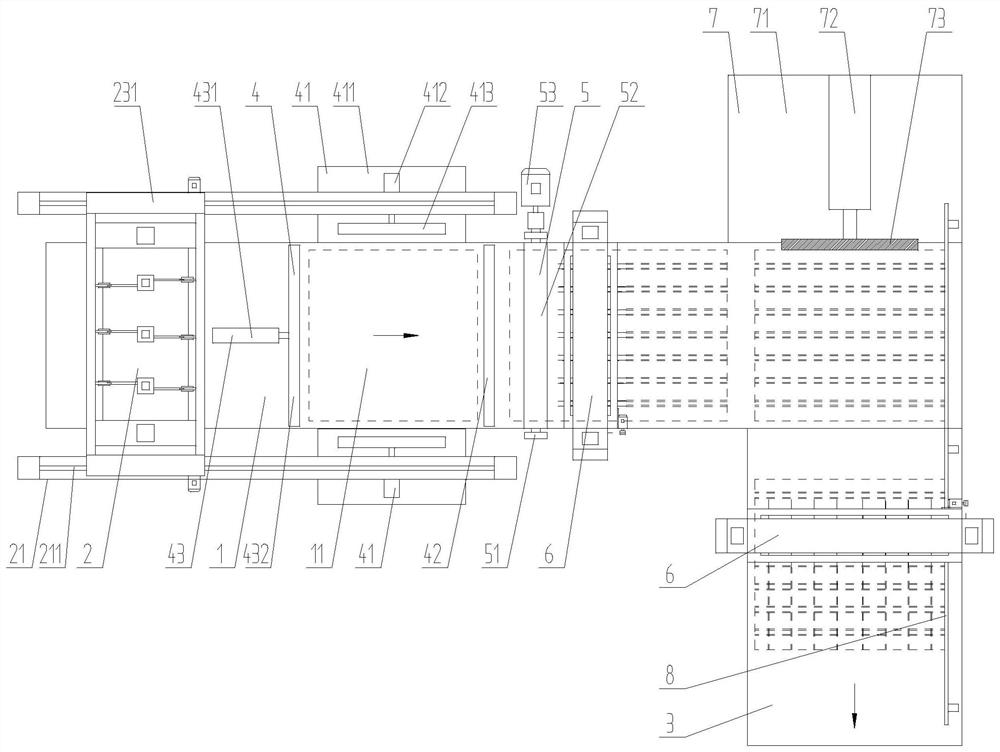

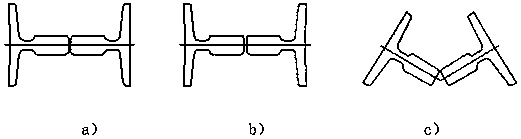

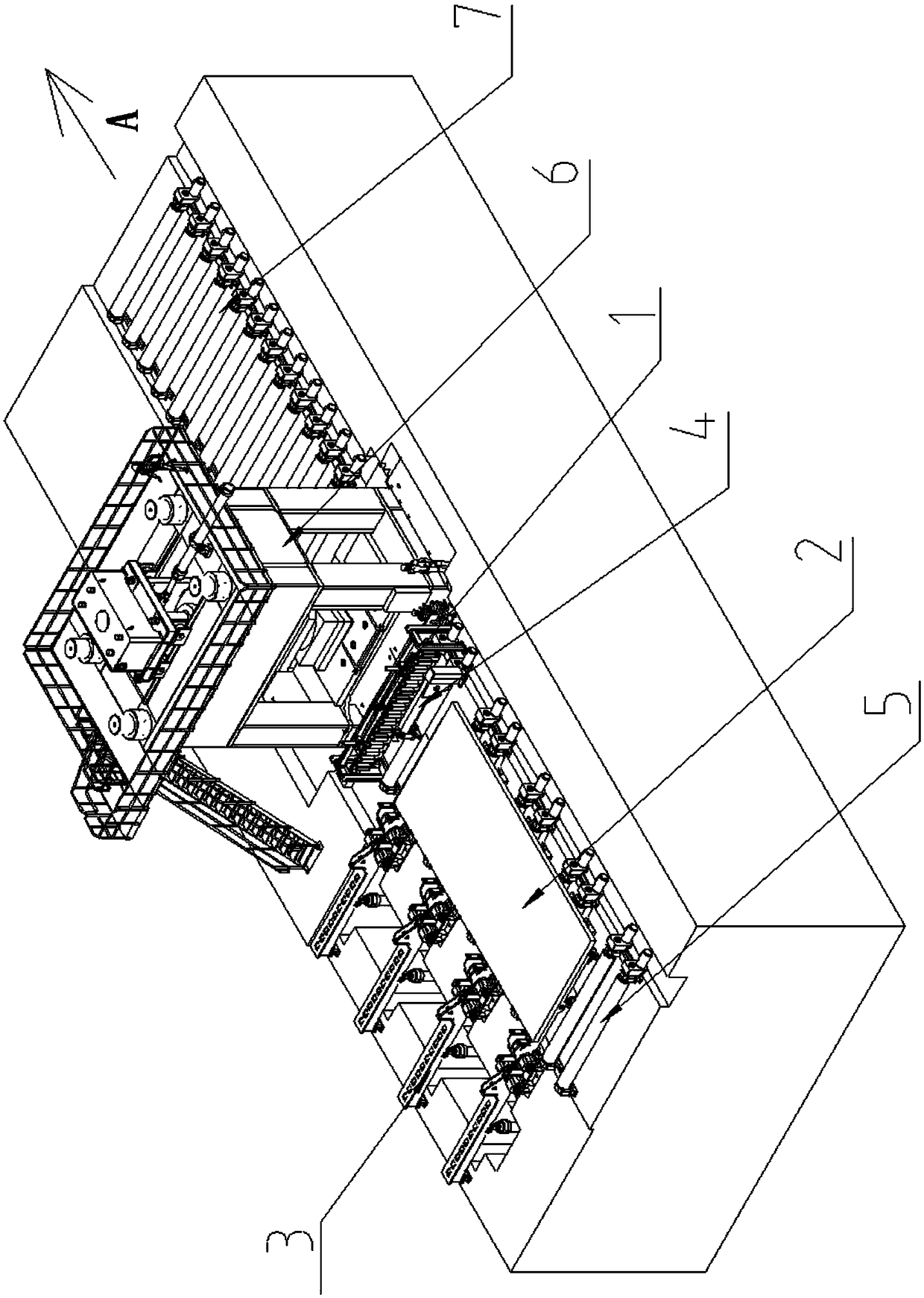

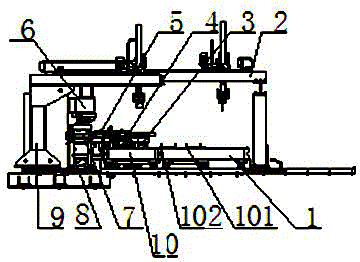

U shaped beam three-face punching technique and production device using the technique

InactiveCN101386046AThe punching position is accurateReduce manufacturing costShaping toolsPerforating toolsShaped beamPunching

The invention discloses a three-side-punch process of a U-shaped beam and a production device used in the process. The process comprises the following steps: the U-shaped beams are placed on a feeding platform, a feed picking device is adopted to successively pick up the spare U-shaped beams and hoist the beams to a support roller of the feeding end; a first feeding clamping device is adopted to clamp the U-shaped webs and feed the webs to working platforms of a ventral small punching machine which can move along the X / Y axis and a ventral large punching machine which can move along the Y axis; the ventral small punching machine which can move along the X / Y axis and the ventral large punching machine which can move along the Y axis punch the beams; a second feeding clamping device clamps the U-shaped beams and continuously feed the beams to the working platform of a left wing punching machine and a right wing punching machine; the left wing punching machine and the right wing punching machine punch the beams; the U-shaped beams are hoisted to a discharging platform after being fully punched. The invention has the advantages of simple process, high production efficiency, low cost and reasonable process arrangement; and the produced U-shaped beams have precise punching location.

Owner:JINAN CASTING FORGING MACHINERY INST

Combined production method of isopropanol and methyl isobutyl ketone

InactiveCN103420792ALow costImprove stabilityOrganic compound preparationHydroxy compound preparationChemical industryReaction temperature

The invention relates to a combined production method of isopropanol and methyl isobutyl ketone. The combined production method is shown as follows: acetone and hydrogen are used as raw materials, a non-noble metal catalyst especially a catalyst produced by Beijing research institute of chemical industry and with a brand number of BC-A-60 is used, the isopropanol and the methyl isobutyl ketone are simultaneously and combinedly produced under the reaction conditions of the reaction temperature of 170-230 DEG C, the reaction pressure of 1.0-6.0 MPa, the acetone liquid phase space velocity of 0.5-3.0 h<-1> and the hydrogen ketone molar ratio of 0.3-1. The combined production method has the following advantages that the low-cost non-noble metal catalyst is used, the technological process is simple and reasonable and low in energy consumption, two products of the isopropyl alcohol and the methyl isobutyl ketone are simultaneously and combinedly produced, wherein a gap of supply and demand of the isopropyl alcohol and the methyl isobutyl ketone is existed in markets, and by-product heavy components are few.

Owner:ZHEJIANG XINHUA CHEM +1

Method for coproduction of methyl isobutyl ketone and methyl isobutyl carbinol

ActiveCN103420786ALow costImprove stabilityOxygen-containing compound preparationOrganic compound preparationChemical industryReaction temperature

The invention relates to a method for coproduction of methyl isobutyl ketone and methyl isobutyl carbinol, and particularly to the production method for simultaneously coproducing methyl isobutyl ketone and methyl isobutyl carbinol with acetone and hydrogen as raw materials, employing a non-pure noble metal catalyst especially employing a catalyst with a brand number of BC-A-61 and produced by Beijing Research Institute of Chemical Industry, and under reaction conditions of the reaction temperature of 170-230 DEG C, the reaction pressure of 1.0-6.0 MPa, the acetone liquid phase airspeed of 0.5-3.0 h<-1> and the hydrogen and ketone molar ratio of 0.3-1. The method of the invention has the advantages of relatively low catalyst cost, reasonable and simple technological process and low energy consumption, simultaneously coproduces two kinds of products which are methyl isobutyl ketone and methyl isobutyl carbinol and have supply and demand gaps existing in markets, and has few by-product heavy components.

Owner:ZHEJIANG XINHUA CHEM +1

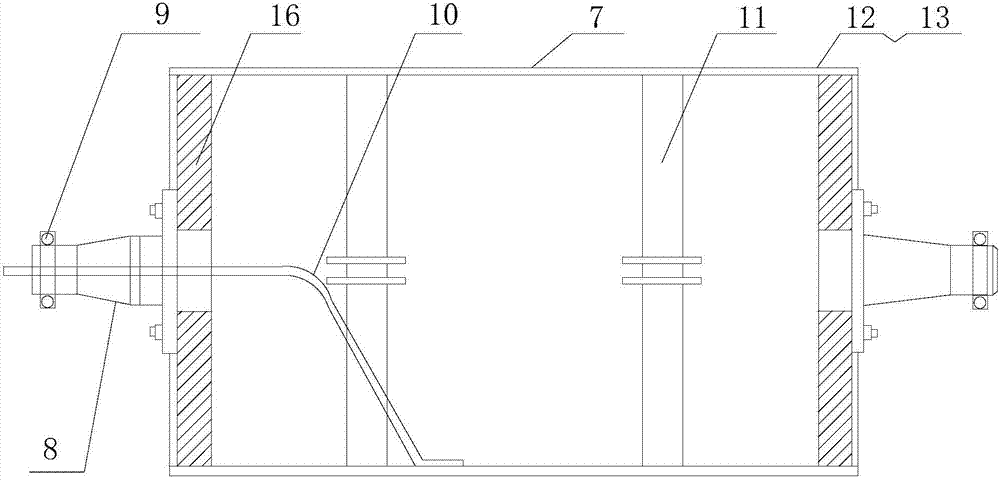

Air cooler for cooling DC converter valve and fabrication technology thereof

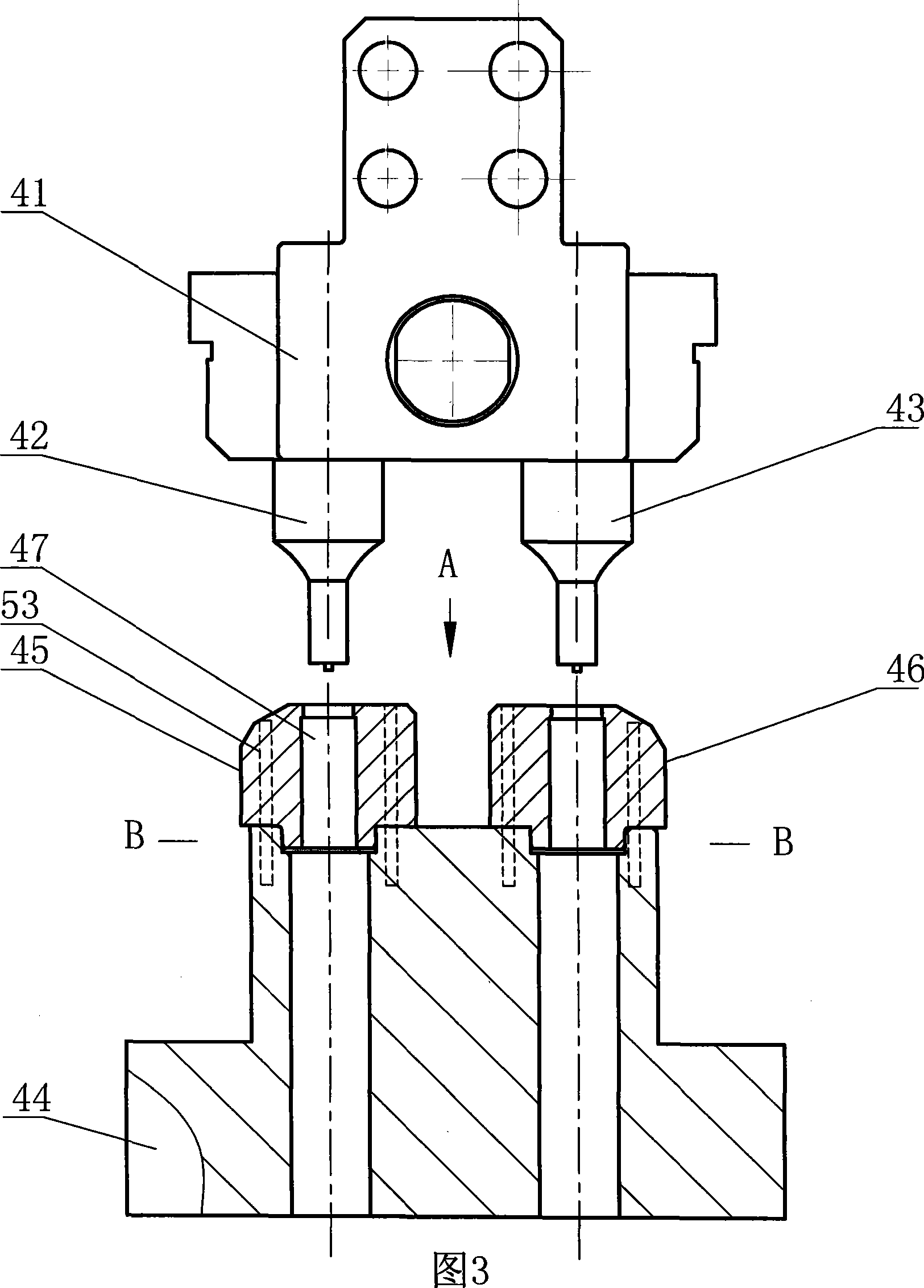

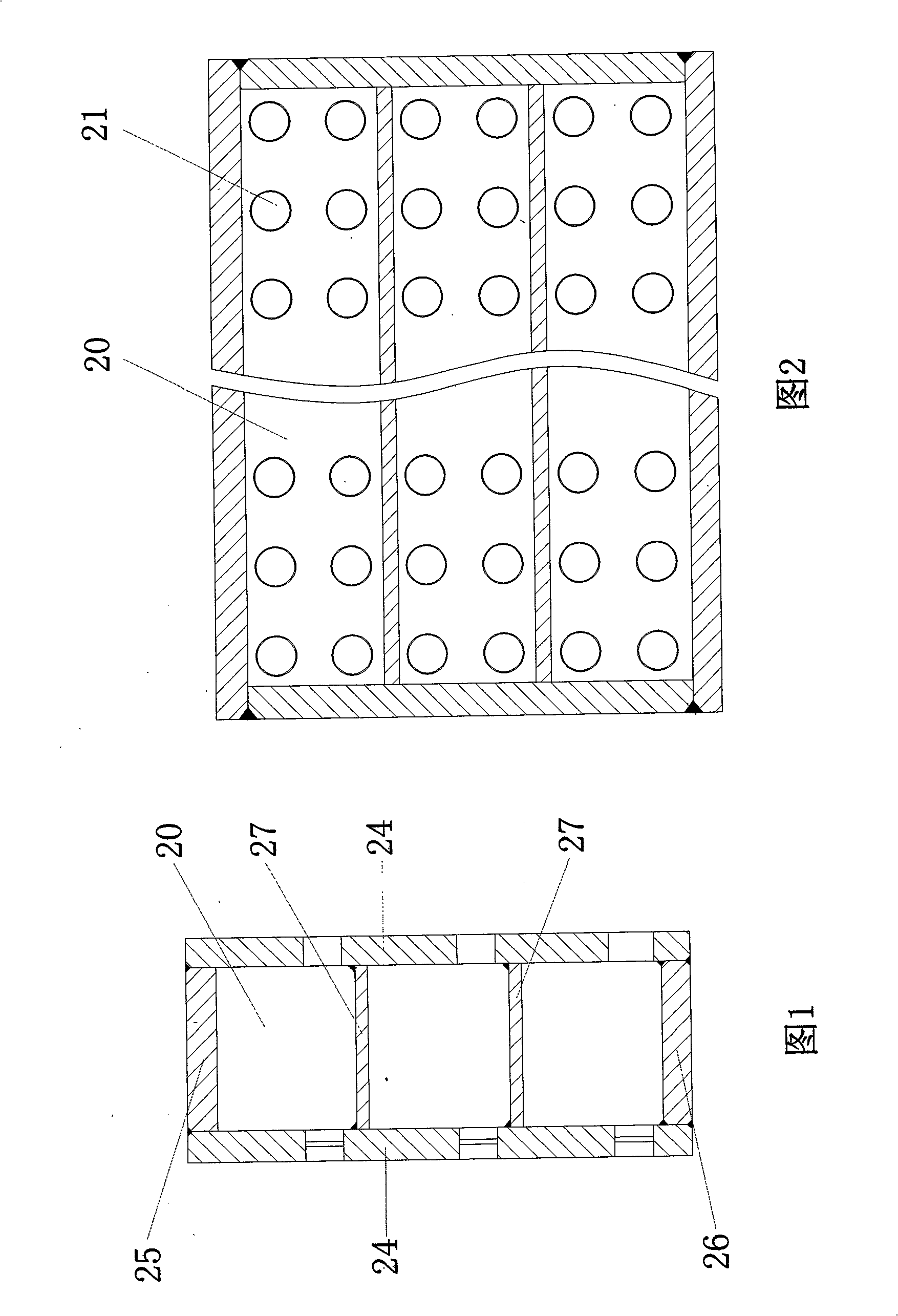

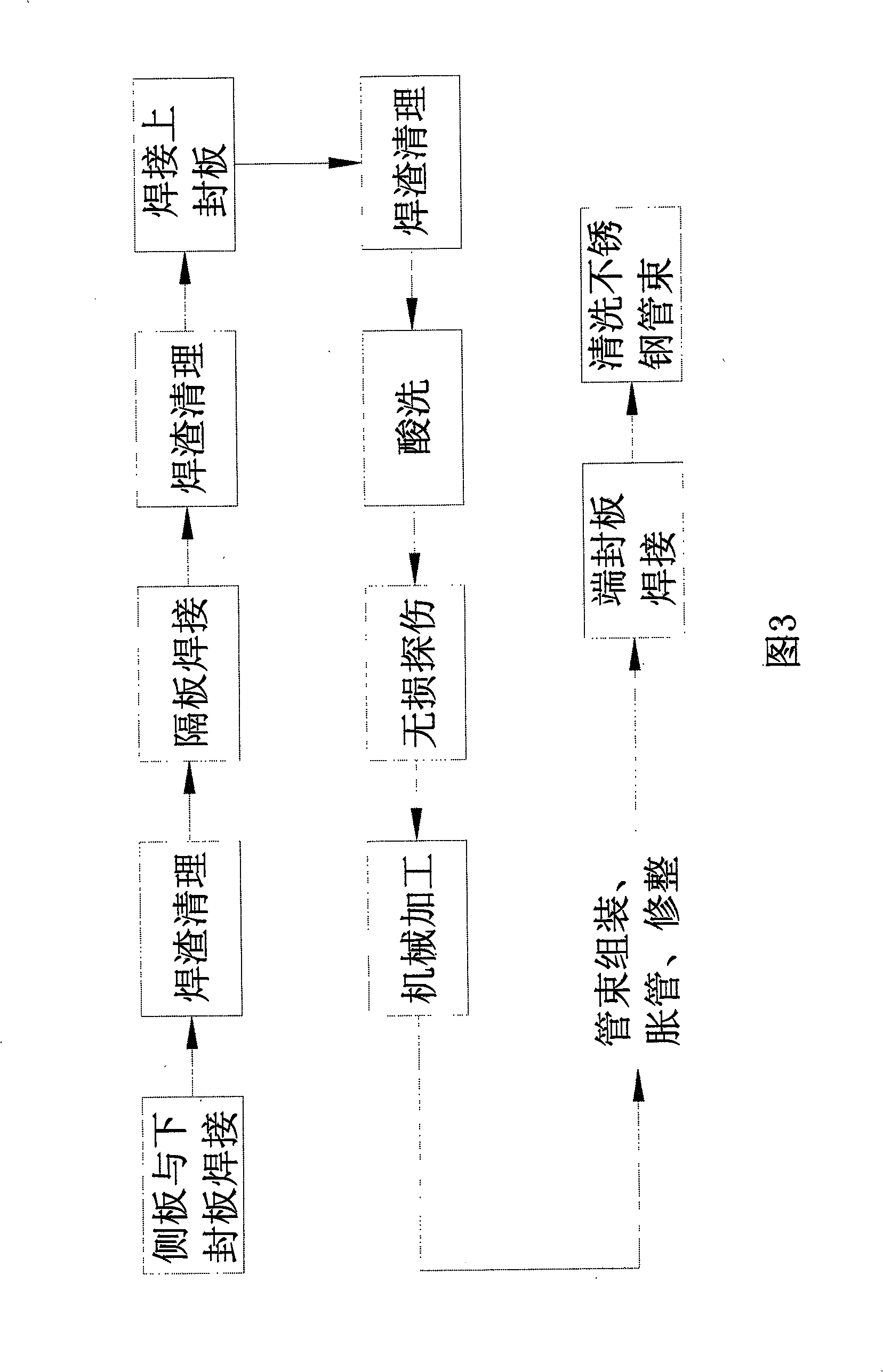

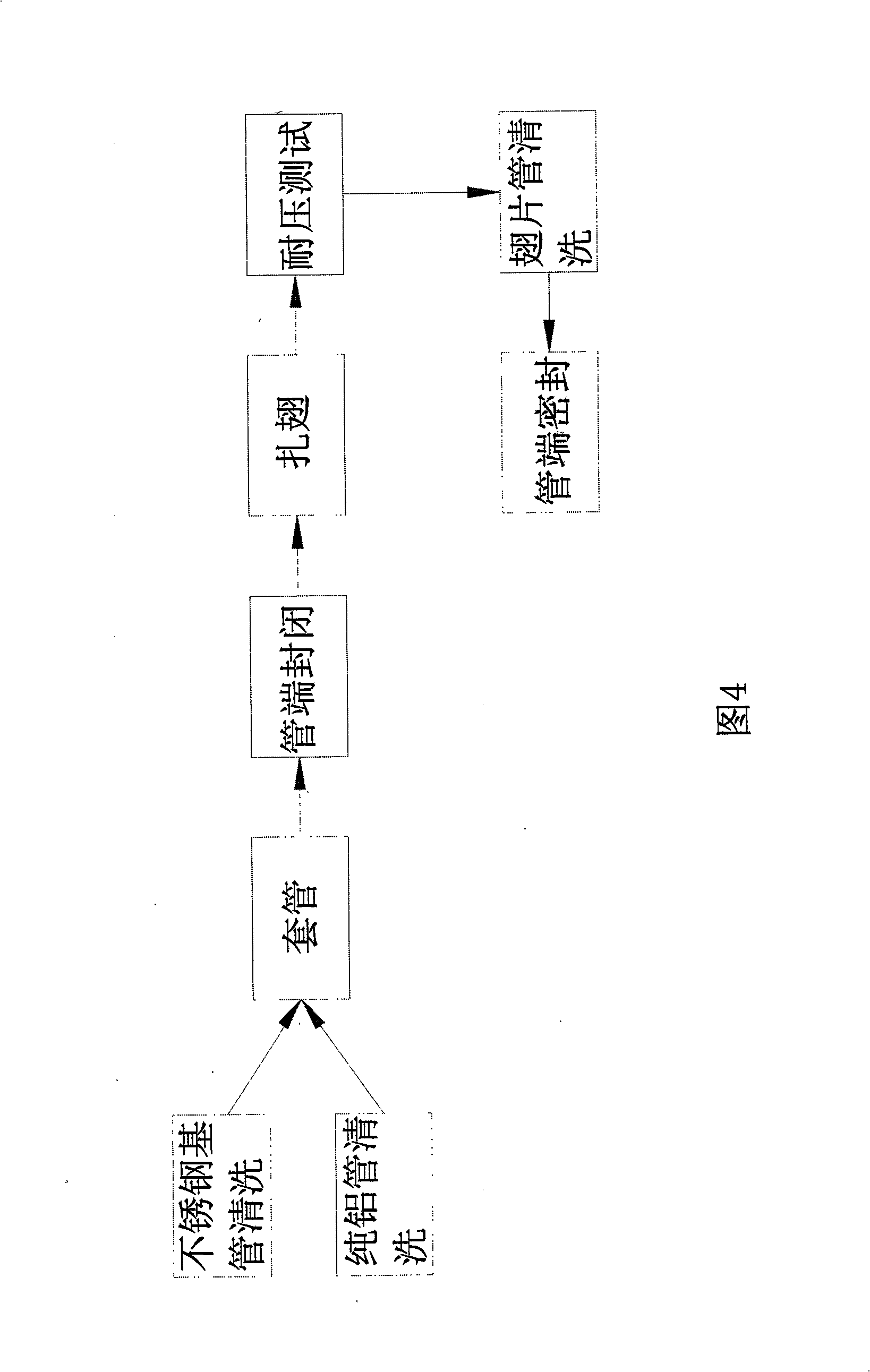

ActiveCN101493300AGuaranteed purityReduced ion extractionSemiconductor/solid-state device detailsSolid-state devicesEngineeringImpurity

The invention discloses an air cooler used for cooling a high voltage direct current transmission converter valve and a manufacturing process thereof. The air cooler comprises a channel box; clapboards are arranged in the channel box to divide the inside of the channel box to a plurality of relatively independent interlayers; a stainless steel tube bank comprising a plurality of stainless steel finned tubes is arranged in the interlayers; the stainless steel finned tube comprises an O6Cr18Ni9 or O6Cr17Ni12Mo2 material parent tube and aluminum rolled fins covering the outside of the parent tube; precipitation amount of ion is decreased to the minimum to ensure the purity of cooling water; specific pre-process treatment of rolled fins effectively decreases thermal resistance between a stainless steel tube and an aluminum tube to improve radiating efficiency; working procedures are arranged reasonably and impurity or roll scale is removed in time, so that the surface of the liquid contacting material of the air cooler is clean to ensure the high purity of fluid.

Owner:岳阳高澜节能装备制造有限公司

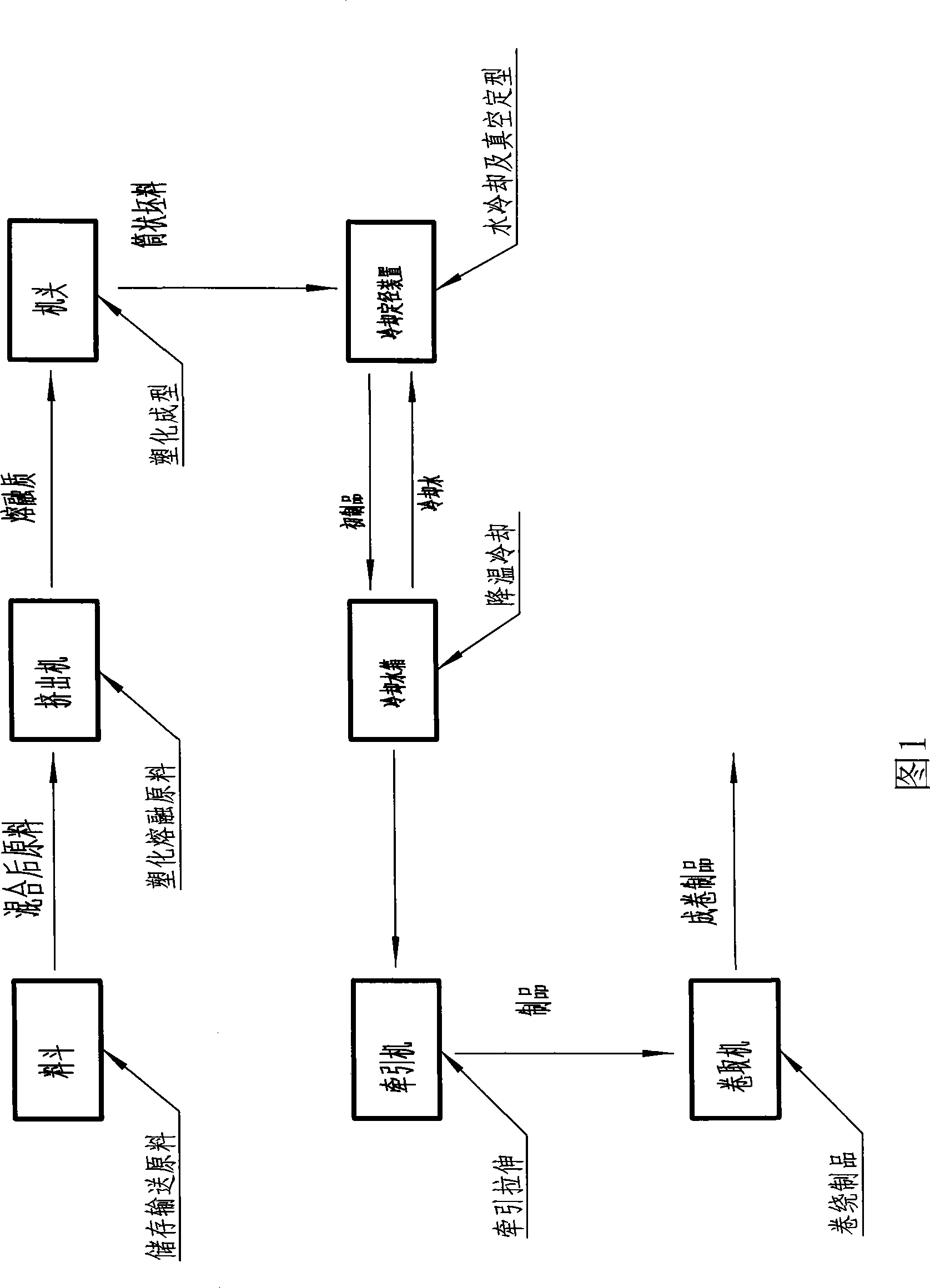

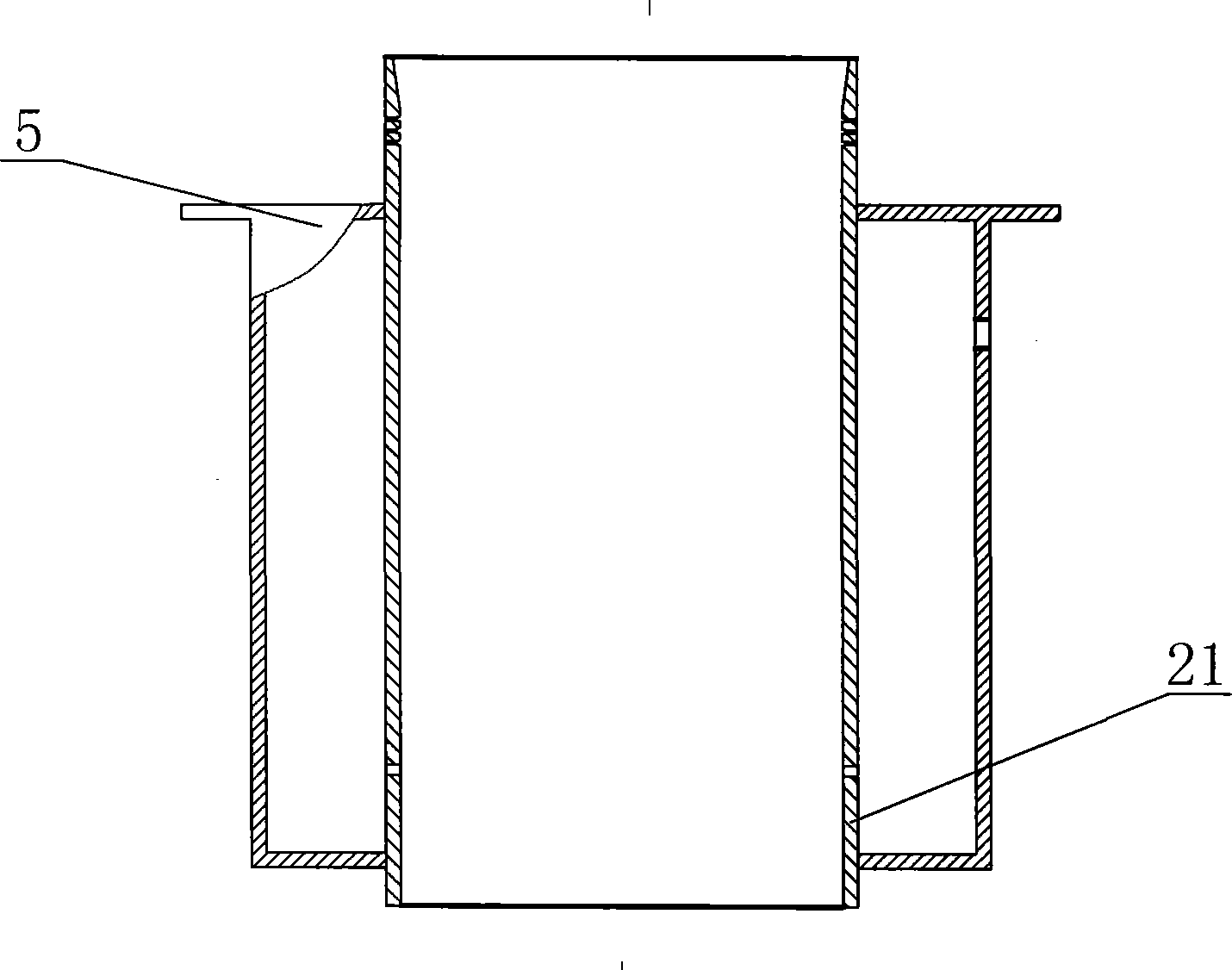

Method and equipment for manufacturing fire engine hose

InactiveCN101249717AGood molding effectImprove molding abilityHollow articlesVacuum pumpingMixed materials

The invention discloses a manufacturing method of a water hose and manufacturing equipment of the water hose. The invention comprises the following processes: firstly, selected materials, color master batches and batches are fully mixed and then put into a container; secondly, the mixed materials are arranged into an extrusion device, the plasticization and melting are performed to the mixed materials to form molten substance, and the molten substance is continuously extruded from the clearance of a shaping mould by the extrusion device, so as to form continuous cylindrical blanks; thirdly, one ends of the cylindrical blanks are hauled by a hauling machine to evenly get into a cooling sizing device, and then the cooling is performed to the walls of the cylindrical blanks through cooling water; fourthly, vacuum pumping is performed to a sizing sleeve in the cooling sizing device, and the cylindrical blanks are sized to form primary products; fifthly, the primary products are hauled into a cooling water tank, the water cooling is performed to the primary products to form finished products. The manufacturing equipment of the water hose realizes the vacuum shaping by being equipped with the devices of a sizing cooling tank and a vacuum pump, etc. The manufacturing method and the manufacturing equipment of the water hose have the advantages of good shaping effect, high cooling speed, low production cost, greatly enhanced product quality and high pressure resistance of the finished products, etc.

Owner:李建国

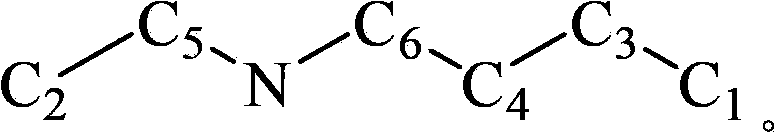

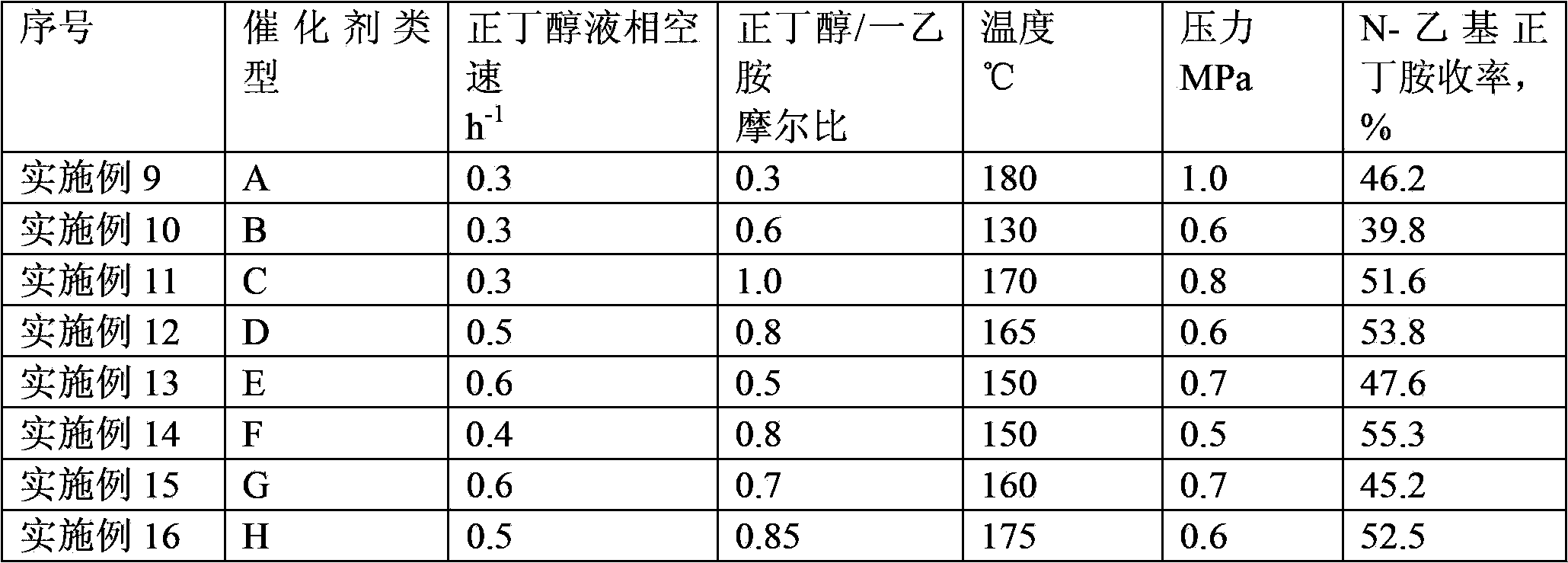

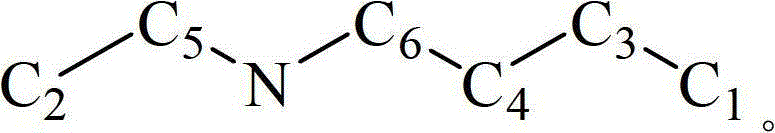

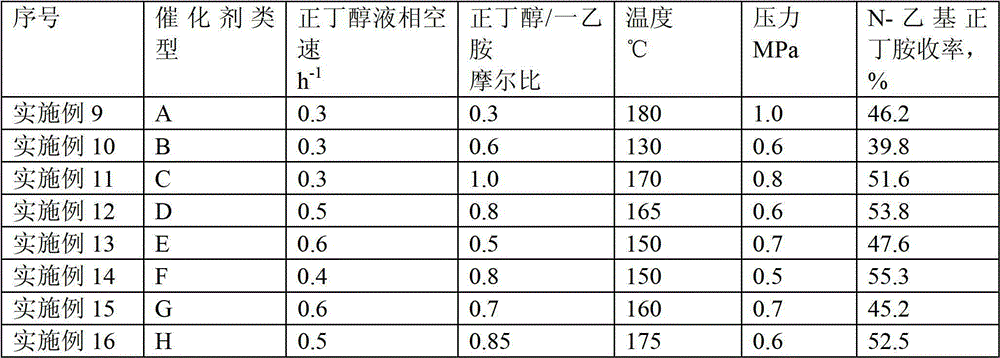

Production method of N-ethyl-n-butylamine

ActiveCN103724210ALow costImprove stabilityOrganic compound preparationAmino compound preparationCeriumReaction temperature

The invention relates to a production method of N-ethyl-n-butylamine. According to the production method, n-butanol and monoethylamine are taken as raw materials; a supported non-noble metal catalyst is used under hydrogen conditions; and amination synthesis of N-ethyl-n-butylamine is performed, wherein a reaction temperature ranges from 120 to 220 DEG C, reaction pressure ranges from 0.1 to 1.2MPa, n-butanol liquid phase airspeed ranges from 0.2 to 1.0h<-1>, and molar ratio of n-butanol to monoethylamine ranges from 0.3 to 1. The supported non-noble metal catalyst used in the production method is a metal active compound-rear earth additive / aluminum oxide supported catalyst, wherein the alumina supporter is alkaline earth metal oxide modified aluminum oxide, the metal active compound comprises at least two selected from copper, cobalt, iron, and zinc; and the additive is a mixture of lanthanum and cerium. Catalyst cost is relatively low; technological processes are reasonable and simple; energy consumption is low; heavy components of byproducts are few; and separation of byproducts is simple.

Owner:ZHEJIANG XINHUA CHEM +1

Cogeneration method of methyl isobutyl ketone and diiso butyl ketone

ActiveCN103755537ALow costImprove stabilityOrganic compound preparationCarbonyl compound separation/purificationCogenerationReaction temperature

The invention relates to a preparation method of a medical intermediate, and particularly relates to a cogeneration method of methyl isobutyl ketone and diiso butyl ketone. The method comprises the following steps: mixing and preheating acetone and isopropanol, entering a reactor containing copper-palladium-zirconium-zinc / molybdenum oxide catalysts; generating a reaction mixed solution of taking methyl isobutyl ketone and diiso butyl ketone as main ingredients from the acetone in a manner of reaction under the conditions that the reaction temperature is 130-210 DEG C, the reaction pressure is 0.1-4.0MPa, the liquid phase airspeed of isopropanol is 0.1-2.5h<-1> and the ketone alcohol mole ratio is 1-7; separating and refining, so as to obtain the methyl isobutyl ketone product and the diiso butyl ketone product. The cogeneration method has the advantages that the use cost of the catalyst is greatly reduced, and the method is low in energy consumption, simple in equipment, free of special requirements, fewer in heavy constituents, high in acetone utilization rate and high in product yield.

Owner:ZHEJIANG XINHUA CHEM

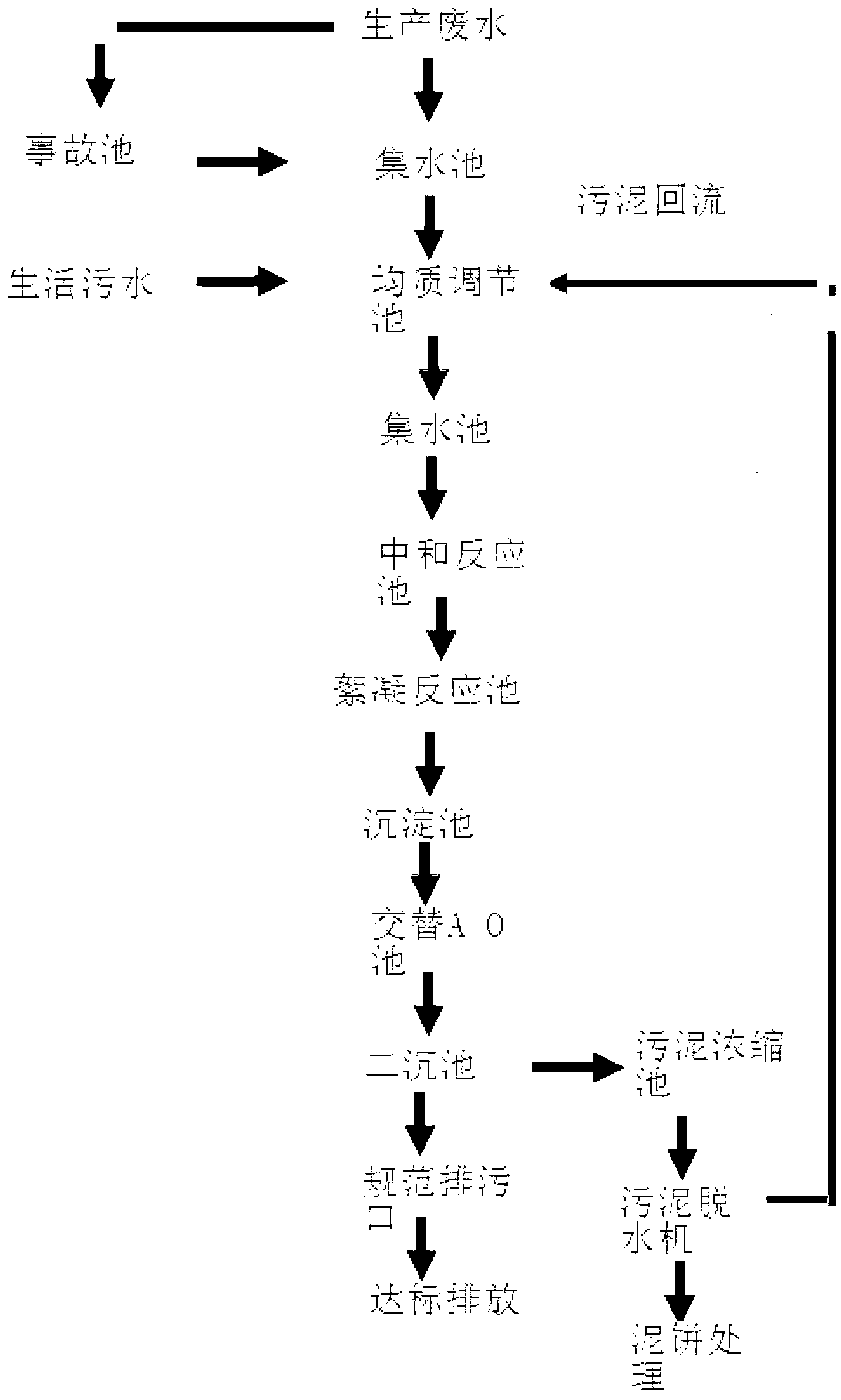

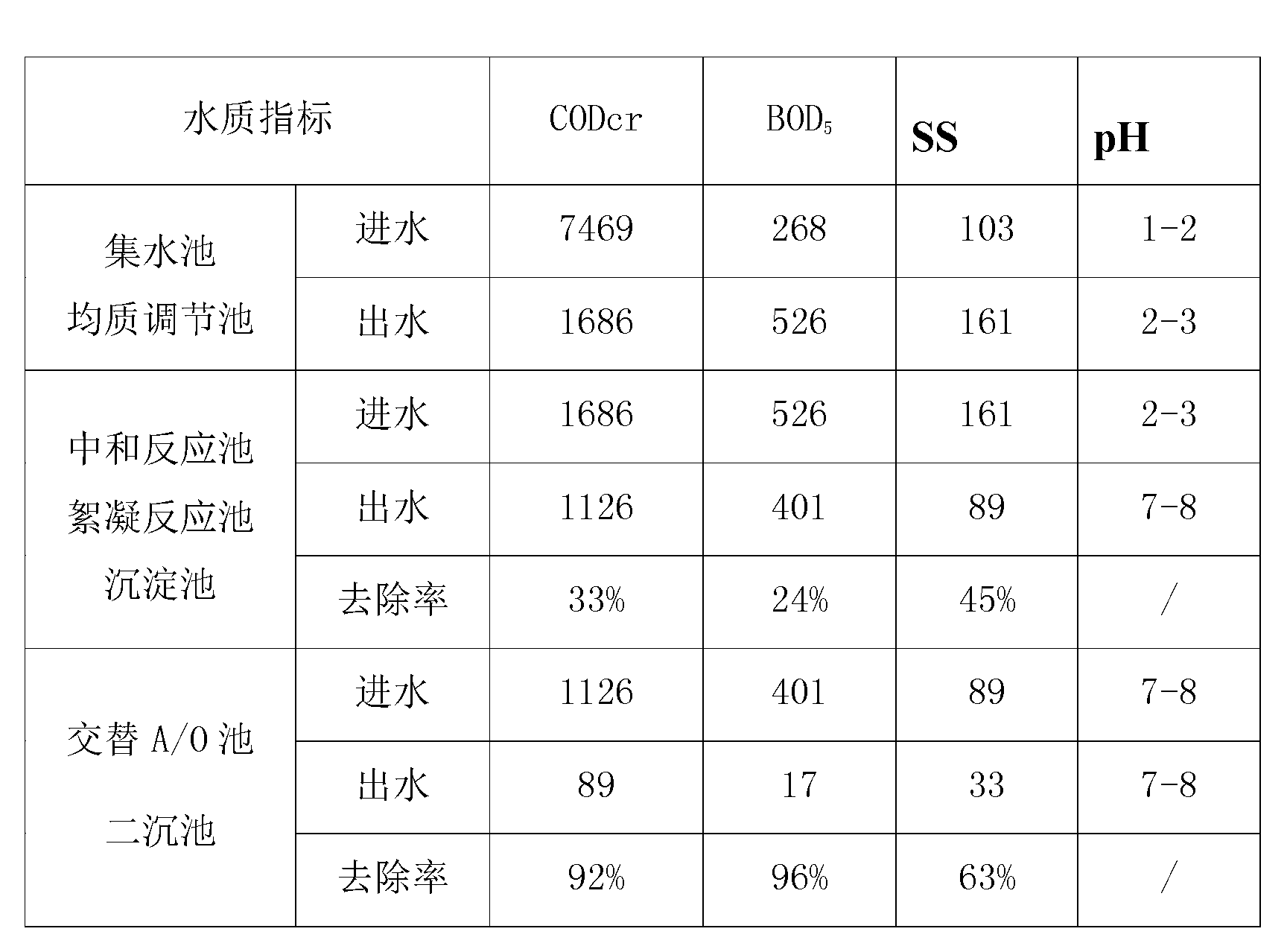

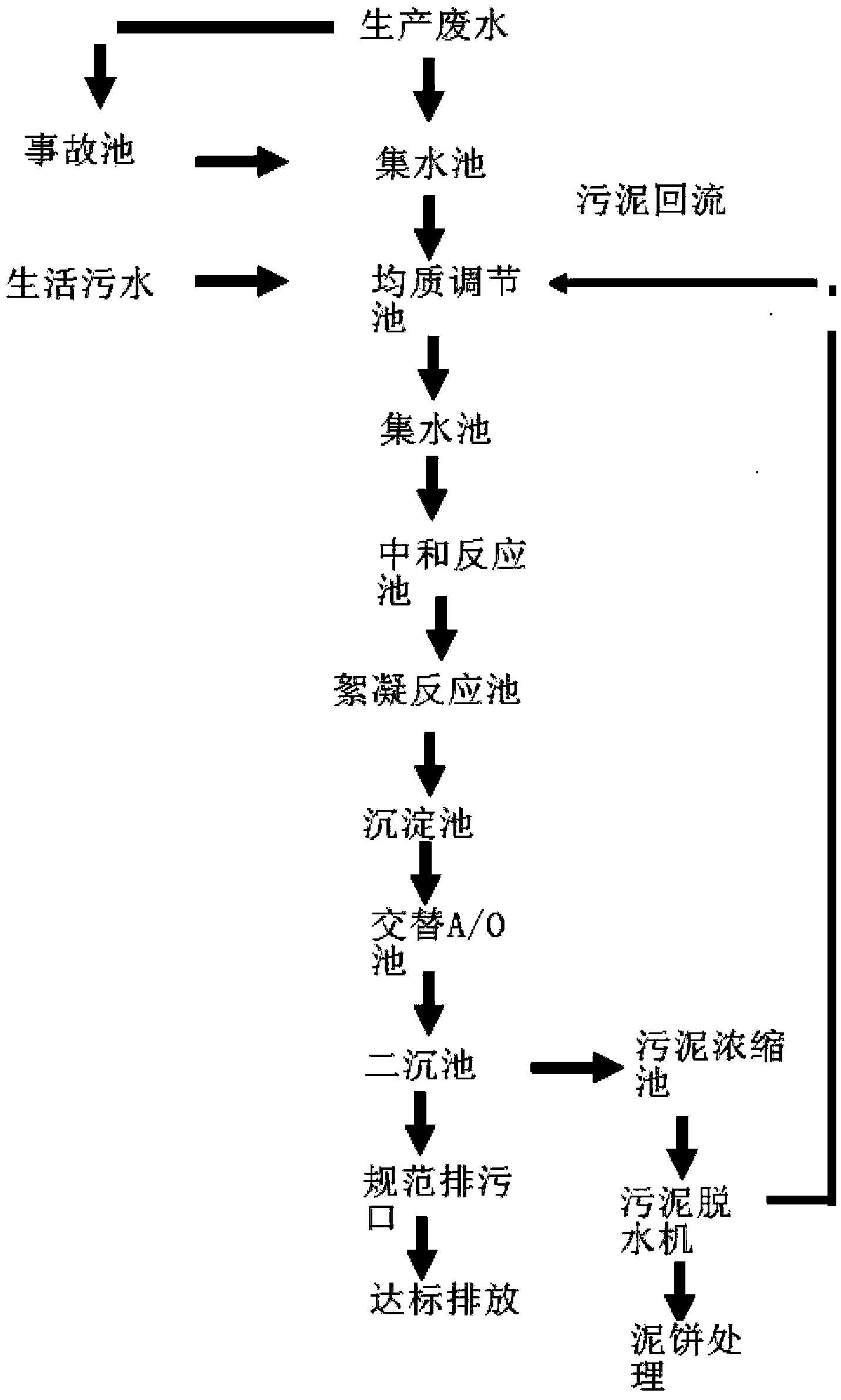

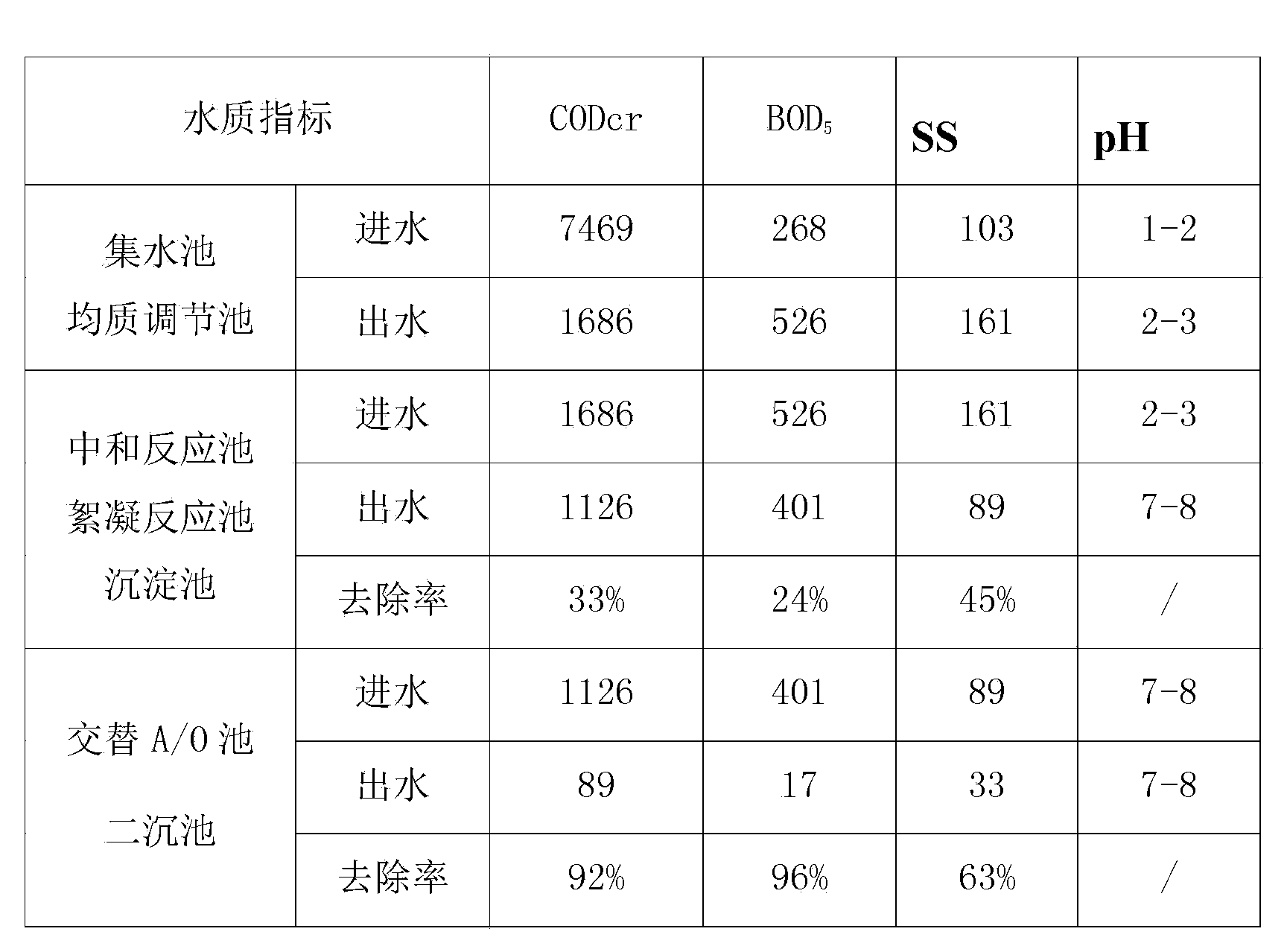

Method for treating poly butylene succinate production waste water by biochemical method

ActiveCN103073156AGuaranteed emission standardsSimple processMultistage water/sewage treatmentWater volumeAluminium chlorohydrate

The invention discloses a method for treating poly butylene succinate production waste water by a biochemical method. The method comprises the following steps of buffering in a water collecting tank, uniformly delivering to a homogeneity regulation tank of a sewage treatment station, mixing with plant domestic sewage in the homogeneity regulation tank, lifting to a neutralization reaction tank by a pump, adding lime milk while stirring, allowing a pH value of the waste water to be 6-9, allowing the waste water to flow automatically into a flocculation reaction tank, adding a PAC (polyaluminium chloride) flocculant constantly, allowing fine suspended substances and colloidal substances in the waste water to gather into alum floc with a larger particle size, conducting settlement separation in a settling tank, and allowing supernatant liquid in the settling tank to automatically flow into an A / O biochemical tank for reaction. The method is advanced, practical, mature and reliable in treatment process, requirements on water quality, water volume fluctuation and poor biodegradability can be met, and the treated waste water can be discharged up to a standard.

Owner:ANQING HE XING CHEM

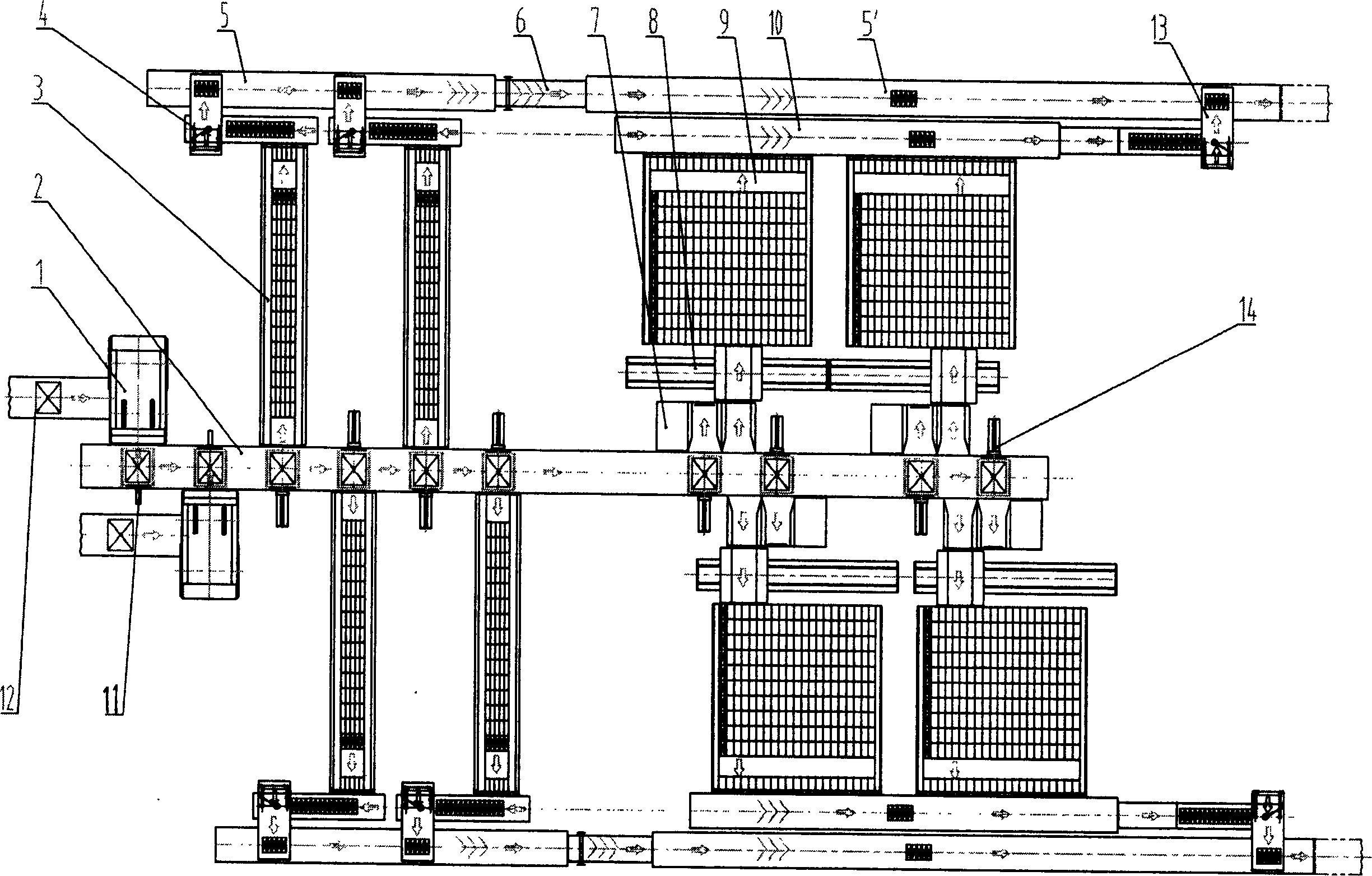

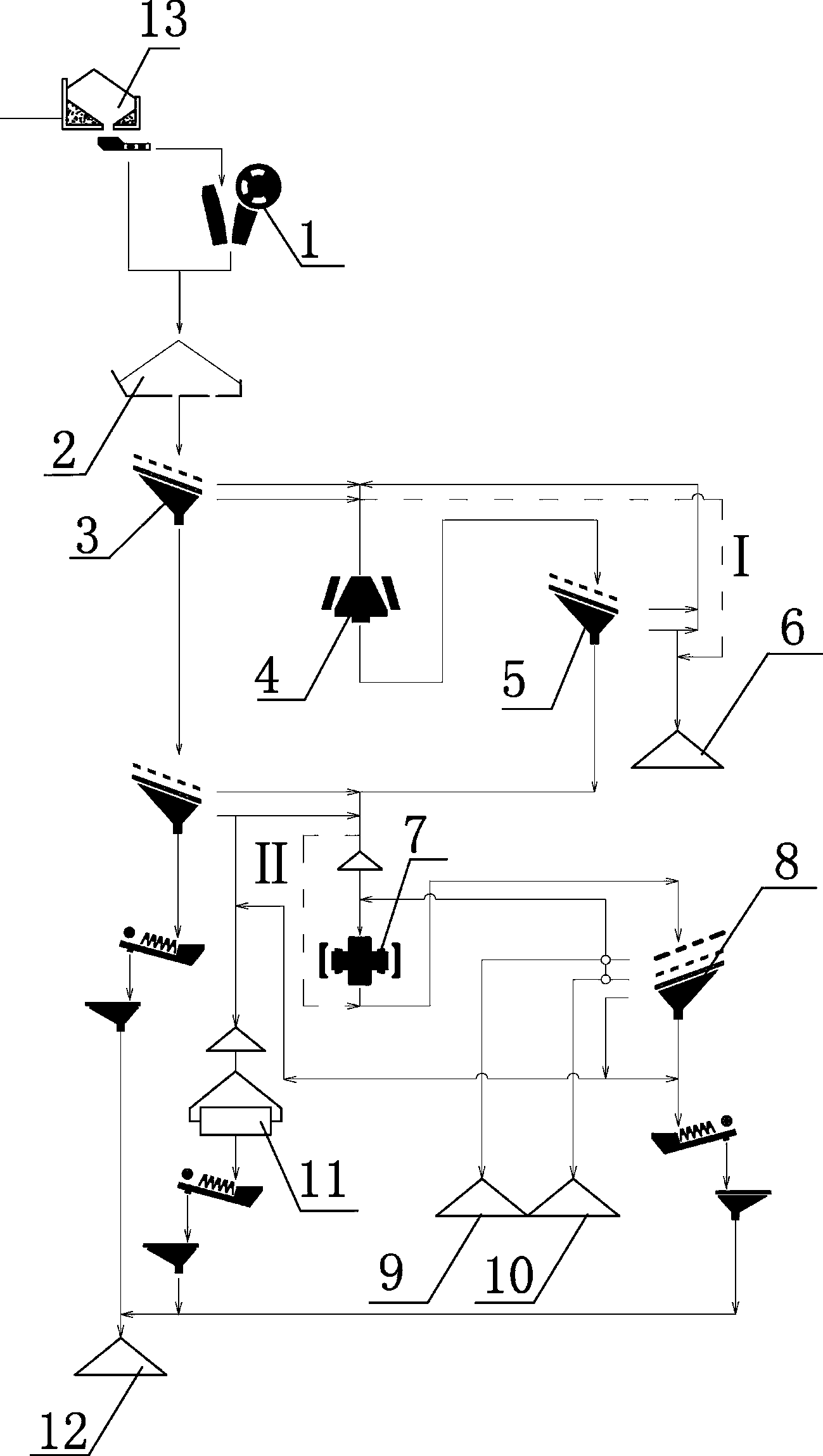

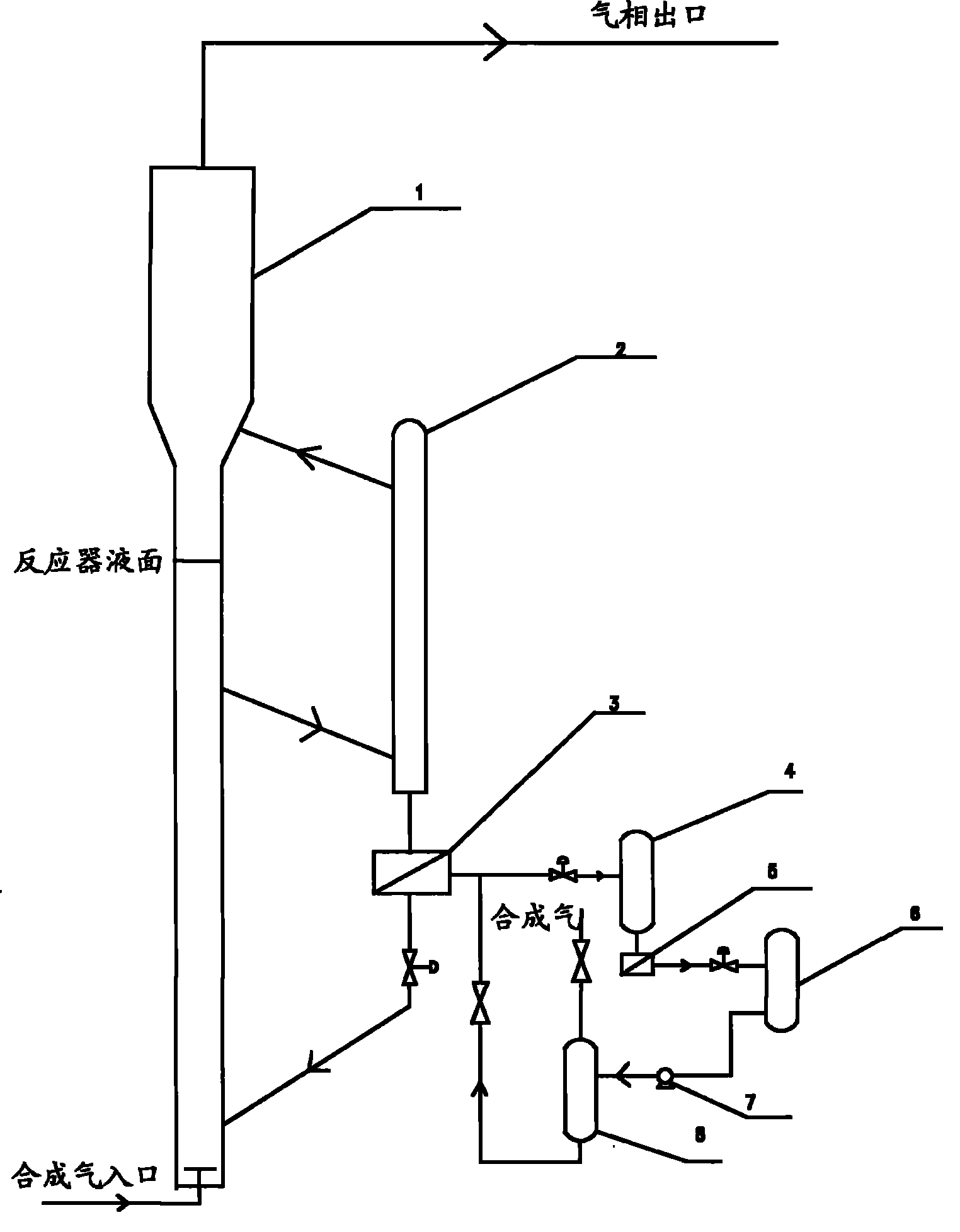

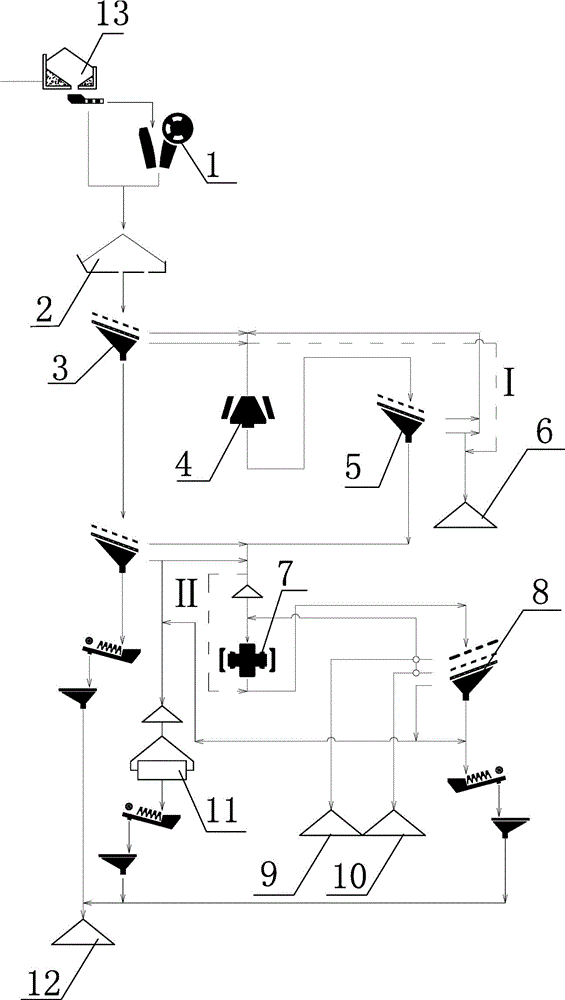

Processing system and method for compatible processing of natural material gravel and artificial hard rock and gravel

ActiveCN103752393AProcess layout is reasonableSmall footprintGrain treatmentsArtificial materialsNatural material

The invention discloses a processing system and a processing method for compatible processing of a natural material gravel and artificial hard rock and gravel. The processing system comprises a stock bin, wherein a coarse crushing device is arranged below the stock bin, and matched with a first screening device; a medium crushing device is arranged behind the first screening device and matched with a second screening device; an ultra-crushing device is arranged behind the second screening device and matched with a third screening device; a rod mill is also arranged inside the processing system. By adopting the system and the method, two independent single-material source gravel systems, namely a land natural material gravel system and an artificial hard rock and gravel system are merged into a hard rock and gravel system and a natural material processing system, and can be compatible to treatment of two gravel materials. Staged production is adopted in a production form; screening equipment is designed according to the natural material when processing equipment is prepared, the crushing equipment is designed according to an artificial material, the maximal load demands are met, and flexible adjustment is carried out through a sealing-tape machine and a slide chute in the staged production, so as to adapt to the requirements of characteristics of different material sources.

Owner:CHINA GEZHOUBA GROUP NO 5 ENG

Equipment for preparing mineral wool and preparation method thereof

InactiveCN108455866AIncrease productivityImprove product qualityCharging furnaceGlass furnace apparatusSlagEngineering

The invention belongs to the technical field of mineral wool preparation, and particularly relates to equipment for preparing mineral wool and a preparation method thereof. The equipment comprises a feeding device, wherein a material dispersing device is arranged below the feeding device, a plurality of heating furnaces are arranged under the material dispersing device, the heating furnaces are connected with a homogenized speed control furnace through pipelines, and the homogenized speed control furnace is connected with a centrifuge. The equipment for preparing the mineral wool adopts stoneor slag as raw materials, solid materials are dispersed into the furnace bodies through the material dispersing device, the materials are widely dispersed in the furnace bodies, and the quick melt ofthe solid materials is convenient; the homogenized speed control furnace is arranged between the heating furnaces and the centrifuge, so that it is ensured that liquid materials intermittently flowingout from the heating furnaces are buffered and can be supplied at a constant speed after homogeneity and heat preservation are carried out according to the requirement of the centrifuge, the heatingefficiency of the whole equipment is high, the arrangement of the process is reasonable, the production efficiency and quality of the mineral wool are greatly improved, and the mineral wool has bettermarket value.

Owner:LUOYANG SIGMA FURNACE

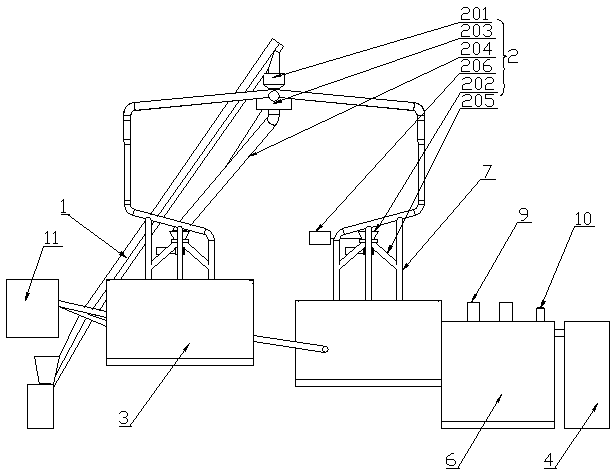

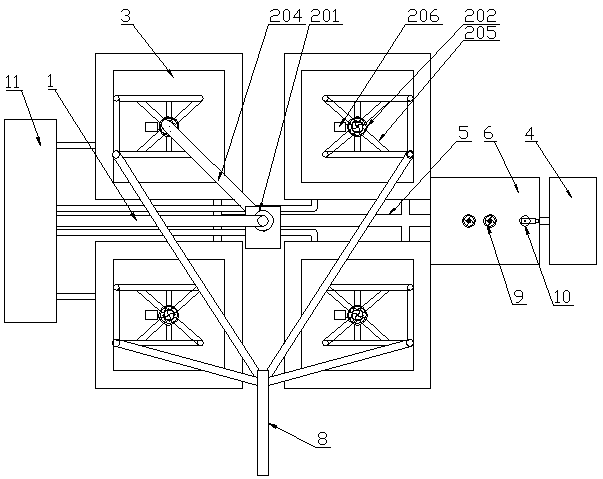

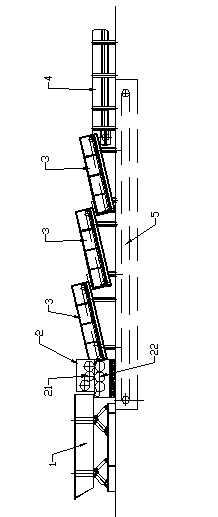

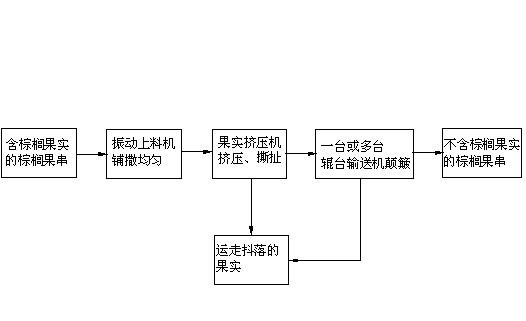

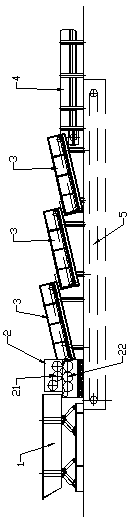

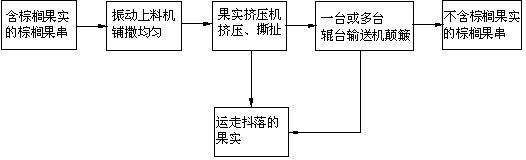

Palm fruit separation device and method

ActiveCN102660879AProcess layout is reasonableSerial productionRaw material pretreatmentPapermakingLower tooth

The invention relates to material preparation technologies in the fields of papermaking or man-made board industries and the like, in particular to a palm fruit separation device and a palm fruit separation method. The device comprises a vibrating feeder, a fruit extruder, roll table conveyors, a fruit bunch belt conveyor and a fruit belt conveyor, which are sequentially connected, wherein the fruit belt conveyor is positioned below the fruit extruder and the roll table conveyors; the fruit extruder comprises a group of upper tooth rollers on an upper part and a group of lower tooth rollers on a lower part; and a fruit bunch with palm fruits passes through a part between the upper and lower tooth rollers, and the fruits are extruded and separated. Mechanical feeding is adopted, and the device and the method are rational in process layout, and have the advantages of production continuity, automatic production process, good fruit separation effect, high yield and the like.

Owner:SUZHOU SUFOMA MACHINERY

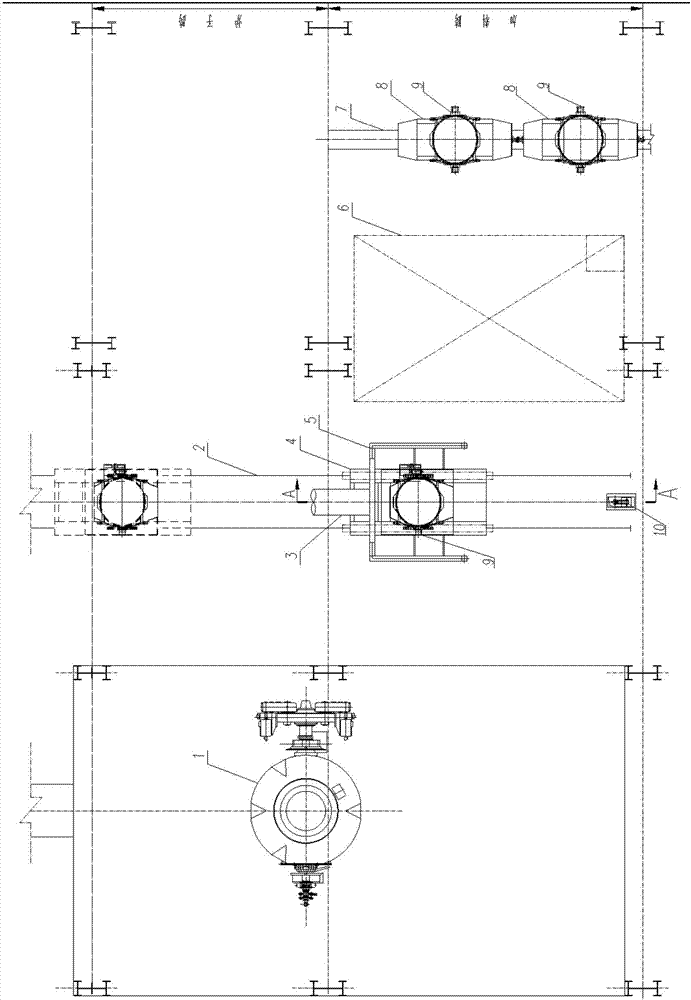

Molten iron reladling system and method based on excess steel return line

ActiveCN107138723AThe process layout is compactWide range of applicationsMelt-holding vesselsSocial benefitsFerric

The invention discloses a molten iron reladling system and method based on an excess steel return line. The molten iron reladling system comprises a charging bay and a furnace bay which are arranged in parallel and an excess steel return vehicle track connected with the charging bay and the furnace bay; the excess steel return vehicle track is provided with an excess steel return vehicle; the excess steel return vehicle track in the charging bay is provided with the molten iron reladling system; the molten iron reladling system comprises a dust treatment device and a weighing device, wherein an empty molten iron ladle is transported to the molten iron reladling system by the excess steel return vehicle so as to be weighed; the dust treatment device is started to reladle molten iron after weighing; after reladling is completed, weighing is performed again and the weight of the reladled molten iron is calculated according to two-time weighing; and the excess steel return vehicle drives out of the molten iron reladling system after weighing. The molten iron reladling system has favorable economic and social benefits for both new steelmaking workshops and reconstruction workshops so as to be well worthy of popularization and application in the future upgrading and reconstruction projects of steelmaking plants.

Owner:HUATIAN NANJING ENG & TECH CORP MCC +1

Wax extraction automatic filter, backwashing system of Ft synthetic pulp bed reactor

ActiveCN101417219BAvoid damageReduce the pressure on fine filtrationHydrocarbon from carbon oxidesLiquid hydrocarbon mixture productionWaxSlurry reactor

The invention discloses a wax extraction automatic filtration and backwashing system used for Fischer-Tropsch synthesis slurry reactor, comprising a filter unit and a backwashing unit, wherein, the filter unit comprises a slurry buffer tank, a wax device external filter (30), a coarse wave outcome buffer tank (4), a wax fine filter (5) and a wax product buffer tank (6); and the backwashing systemcomprises a washing wax pump (7) and a backwashing wax buffer tank (8). The wax extraction automatic filtration and backwashing system has the advantages of reasonable structure, short flow, low energy dissipation, avoiding the blocking or reverse flowing, reducing the damage of catalyst grains, and achieving the stable and continuous running of the Fischer-Tropsch synthesis slurry reactor.

Owner:CHNA ENERGY INVESTMENT CORP LTD +1

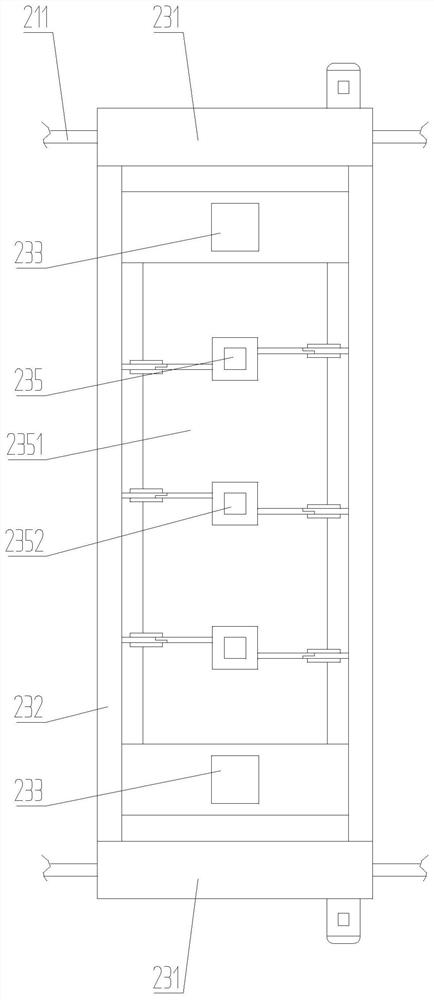

Full-automatic cutting and shaping system of wallboard component filling module

PendingCN113103445ADesign scienceProcess layout is reasonableWorking accessoriesStone-like material working toolsEngineeringReclaimer

The invention discloses a full-automatic cutting and shaping system of a wallboard component filling module. The full-automatic cutting and shaping system comprises a transverse mold table, a material taking robot device and a vertical mold table, the material taking robot device is installed on the left side of the transverse mold table, the vertical mold table is perpendicularly connected to the right end of the transverse mold table, a material arranging mechanism, a pressing roller material conveying mechanism and a cutting robot device are sequentially installed along the transverse mold table from left to right, the cutting robot device is installed on the vertical mold table in a crossing mode, a secondary feeding pushing mechanism is installed on the opposite side of the vertical mold table, a secondary cutting positioning stop lever is installed on the right side of the upper end face of the vertical mold table, and the secondary cutting positioning stop lever extends to the transverse mold table and secondary feeding pushing mechanism. According to full-automatic cutting and shaping system of the wallboard component filling module, all the devices are scientific in design, the process arrangement is reasonable, the material taking and cutting processes are fully automatically carried out, manual cooperation is not needed, filling blocks can be rapidly manufactured in batches, the production requirement is met, and the full-automatic cutting and shaping system has the advantages of being high in production efficiency and low in production cost.

Owner:浙江舜虞达环境科技集团有限公司

Drying room apparatus of warp sizing machine

InactiveCN107475959ADecreased drying coverage factorAppropriate spacingLiquid/gas/vapor removalTextile/flexible product manufactureYarnSlurry

The invention relates to a drying room apparatus of a warp sizing machine, and the drying room body comprises a drying room casing and a steam cover installed on the drying room casing; two sets of exhaust systems are installed on the steam cover; two sets of predrying apparatus and merged drying apparatus are installed in the casing; the predrying apparatus comprises several predrying cylinders; the merged drying apparatus comprises several merged drying cylinders; yarn in a rear slurry groove and a front slurry groove is used to cover the external surface of the predrying cylinders; the yarn on the predrying cylinders is used to cover the merged drying cylinder through the roller installed on the casing; and the yarn on the merged drying cylinder is drawn out through a traction roller and a traction variable frequency motor. The apparatus has the advantages that the drying efficiency is high; the wet zone is short; the technology arrangement is reasonable; overflowing is prevented; droplet in the drying room is avoided; condensation in the workshop is saved; the sizing drying cover coefficient is reduced to a half; proper spacing in sizing in the drying process is guaranteed; falling of slurry and object is reduced in leasing; the yarn surface is smooth; the hairiness is neat; and constant tension force of the dry zone and the wet zone is guaranteed.

Owner:周秋野

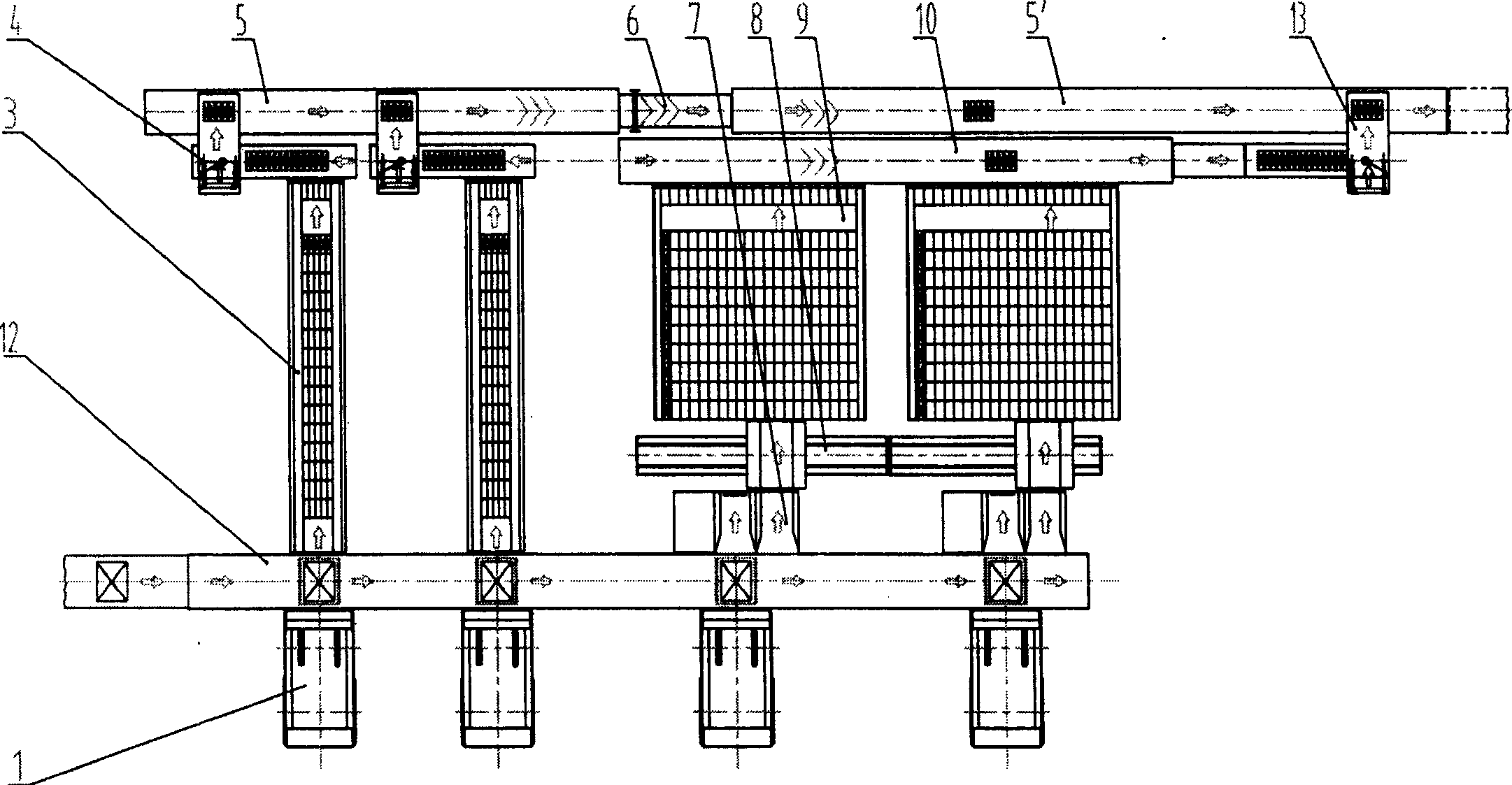

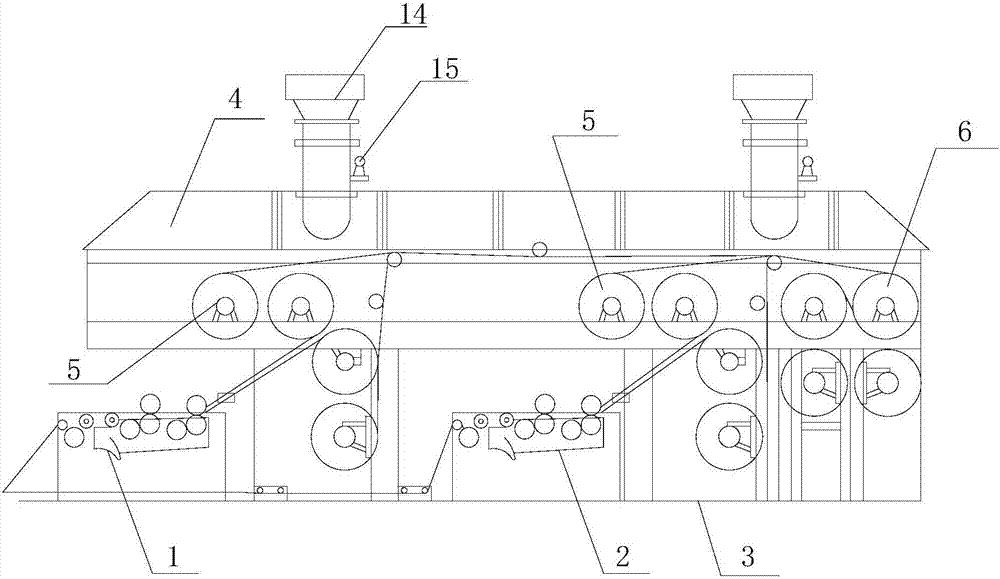

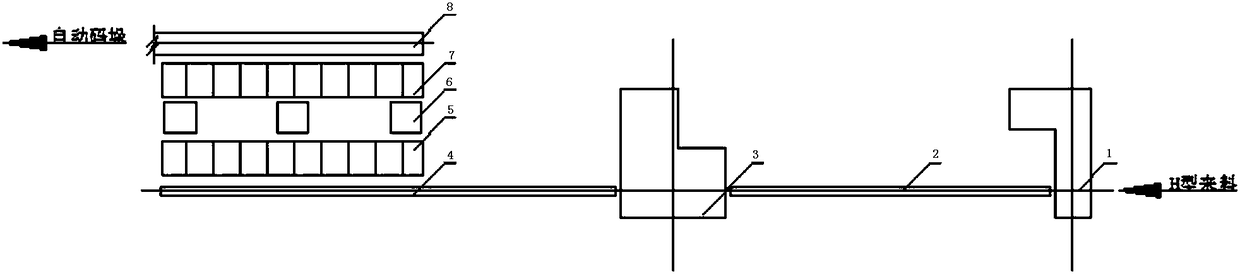

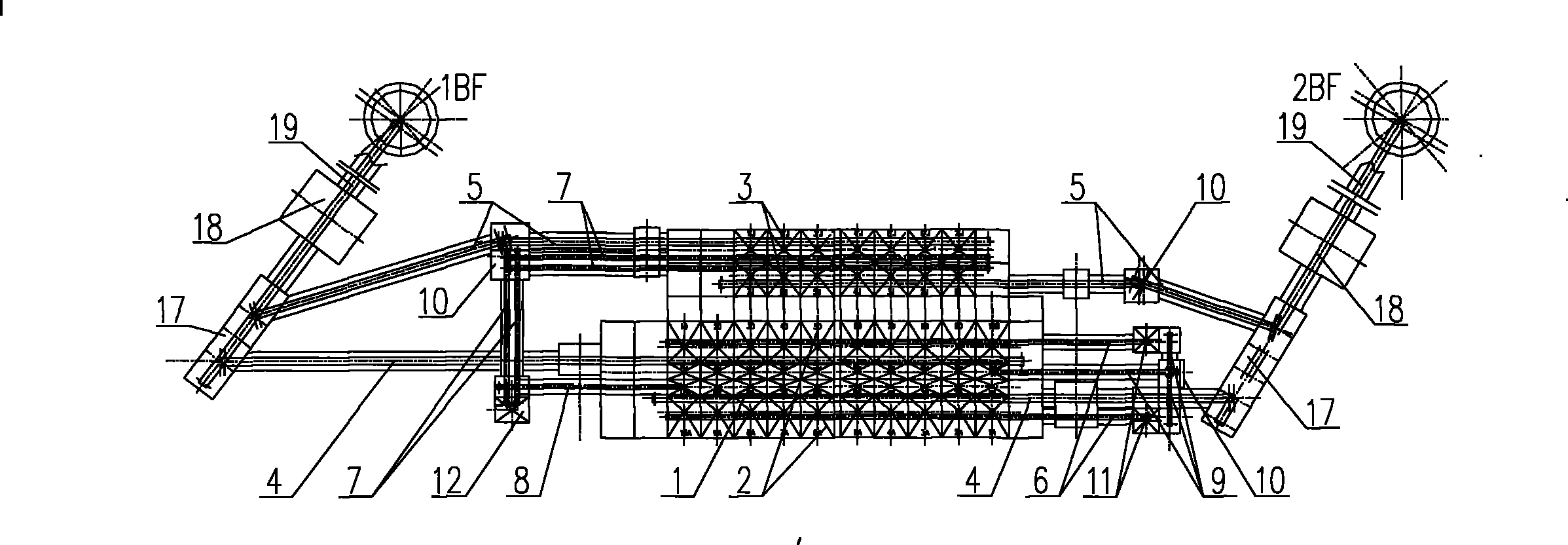

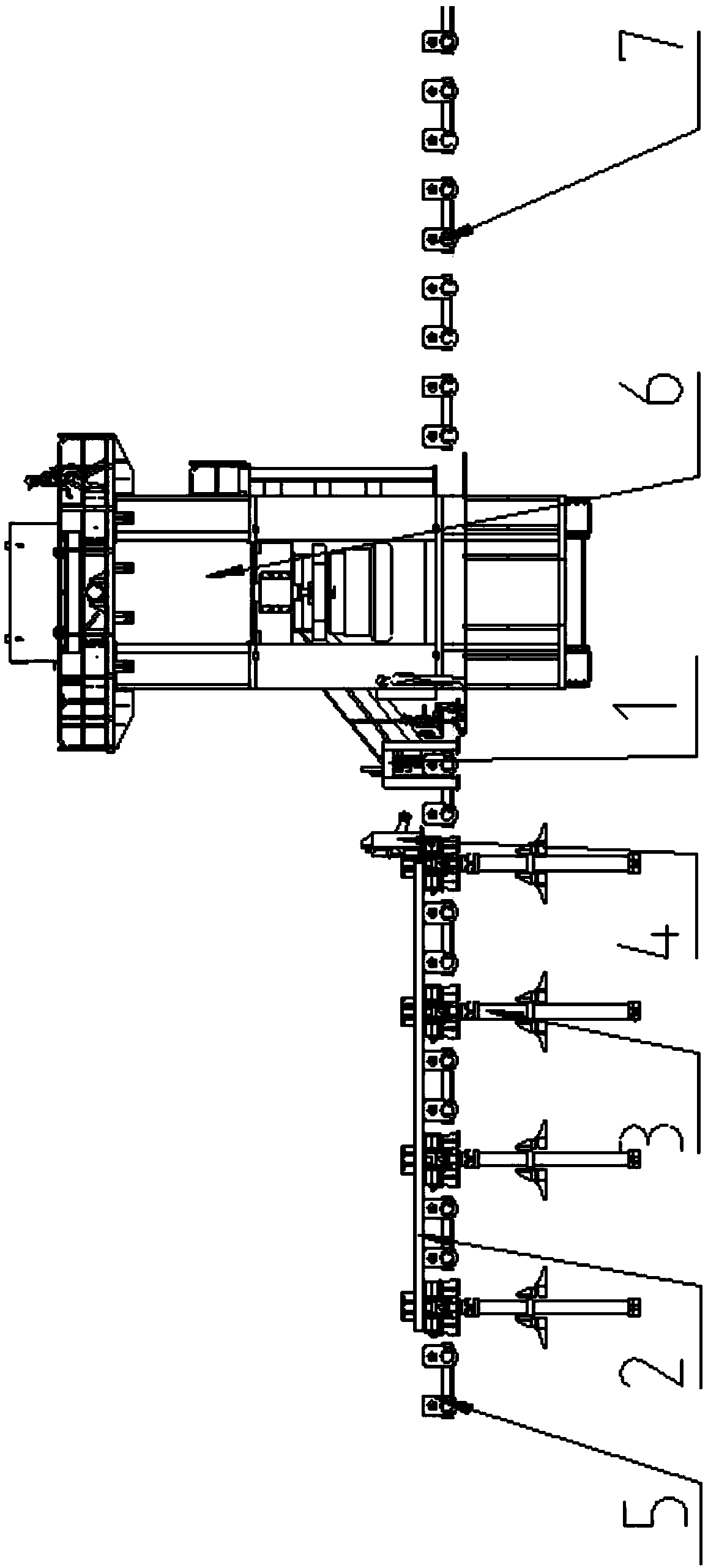

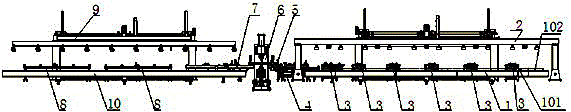

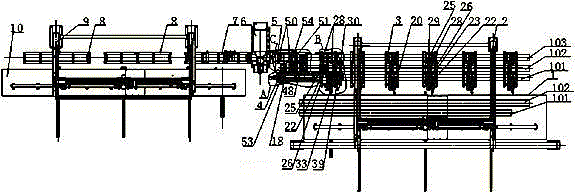

On-line continuous sectioning, straightening and sawing in pairs to produce elevator guide rail finishing equipment and method

ActiveCN105583631BGood labor conditionsProcess layout is reasonableOther manufacturing equipments/toolsEngineeringProduction quality

The invention discloses an online continuous sectioning, straightening and sawing equipment and method for producing elevator guide rails in pairs. Invented to solve the problems of low production efficiency in the prior art. The online continuous sectioning, straightening, and sawing paired production elevator guide rail finishing equipment of the present invention at least includes: a splitting machine, a rear roller table of the splitting machine, a double-slot straightening machine, a row of benches in front of the saw, a sawing unit, Turning steel platform, stacking input roller table; the invention adopting the above structure has the advantages of reasonable process layout, convenient operation, smooth operation, high production efficiency, stable and controllable production quality, high automation level and good labor conditions of workers.

Owner:HUATIAN ENG & TECH CORP MCC

The production method of n-ethyl n-butylamine

ActiveCN103724210BLow costImprove stabilityOrganic compound preparationAmino compound preparationReaction temperatureCerium

The invention relates to a production method of N-ethyl-n-butylamine. According to the production method, n-butanol and monoethylamine are taken as raw materials; a supported non-noble metal catalyst is used under hydrogen conditions; and amination synthesis of N-ethyl-n-butylamine is performed, wherein a reaction temperature ranges from 120 to 220 DEG C, reaction pressure ranges from 0.1 to 1.2MPa, n-butanol liquid phase airspeed ranges from 0.2 to 1.0h<-1>, and molar ratio of n-butanol to monoethylamine ranges from 0.3 to 1. The supported non-noble metal catalyst used in the production method is a metal active compound-rear earth additive / aluminum oxide supported catalyst, wherein the alumina supporter is alkaline earth metal oxide modified aluminum oxide, the metal active compound comprises at least two selected from copper, cobalt, iron, and zinc; and the additive is a mixture of lanthanum and cerium. Catalyst cost is relatively low; technological processes are reasonable and simple; energy consumption is low; heavy components of byproducts are few; and separation of byproducts is simple.

Owner:ZHEJIANG XINHUA CHEM +1

Disc filter filtrate steam-water separation device

ActiveCN105126423BLow costReduce consumptionMoving filtering element filtersAir volumeProcess configuration

The invention relates to a disc type filtrate steam and water separation device of a filter. The disc type filtrate steam and water separation device comprises an adsorption system, a dehydrating system, an air blowing unloading system and an electric control system; the adsorption system comprises an adsorption liquid discharging tank, an adsorption vacuum pipe, an adsorption vacuum pump, an adsorption vacuum venting pipe, an adsorption liquid discharging pipe and an adsorption flap valve; the adsorption liquid discharging tank is connected with the filter, the dehydrating system comprises a dehydrating liquid discharging tank, a dehydrating vacuum pipe, a dehydrating vacuum pump, a dehydrating vacuum venting pipe, a dehydrating liquid discharging pipe and a dehydrating flap valve; the dehydrating liquid discharging tank is connected with the filter, the air blowing unloading system comprises an air blowing pipe, a gas storage tank and a blower. The air blowing pipe is provided with an air volume control valve, and a blow-down valve is arranged at the bottom of the gas storage tank. Dehydrating and absorption in a filtering process are independently finished, and the difficult problem that the size of a filtrate tank depends on the area of the filter in a traditional process is solved, so that the process configuration is more reasonable, the plant constructing cost is lower, water and electricity cost as well as consumption of devices and spare parts are reduced.

Owner:鞍钢集团矿业设计研究院有限公司

Palm fruit separation device and method

ActiveCN102660879BEasy to separateProcess layout is reasonableThreshersMaterials preparationPalm fruit

Owner:SUZHOU SUFOMA MACHINERY

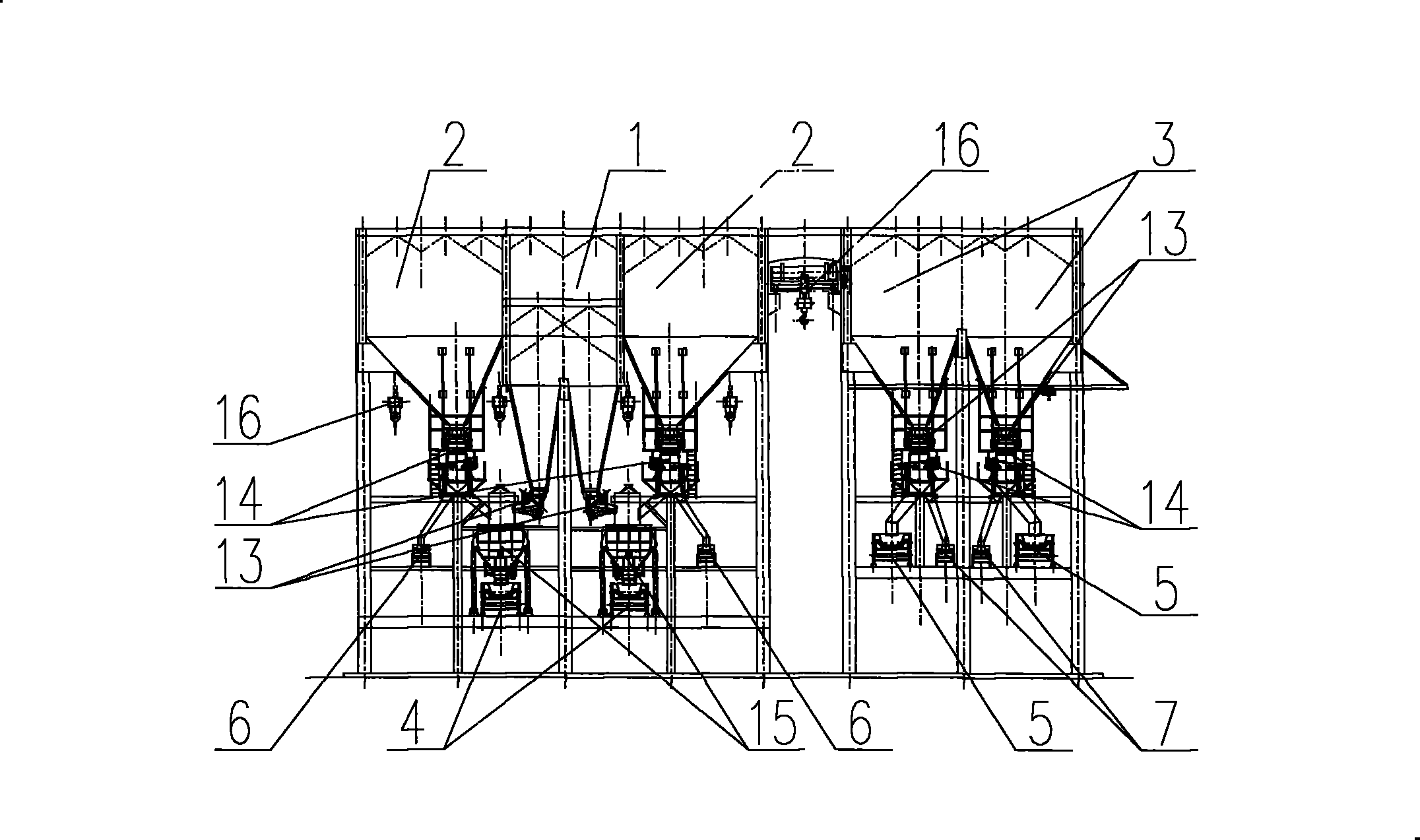

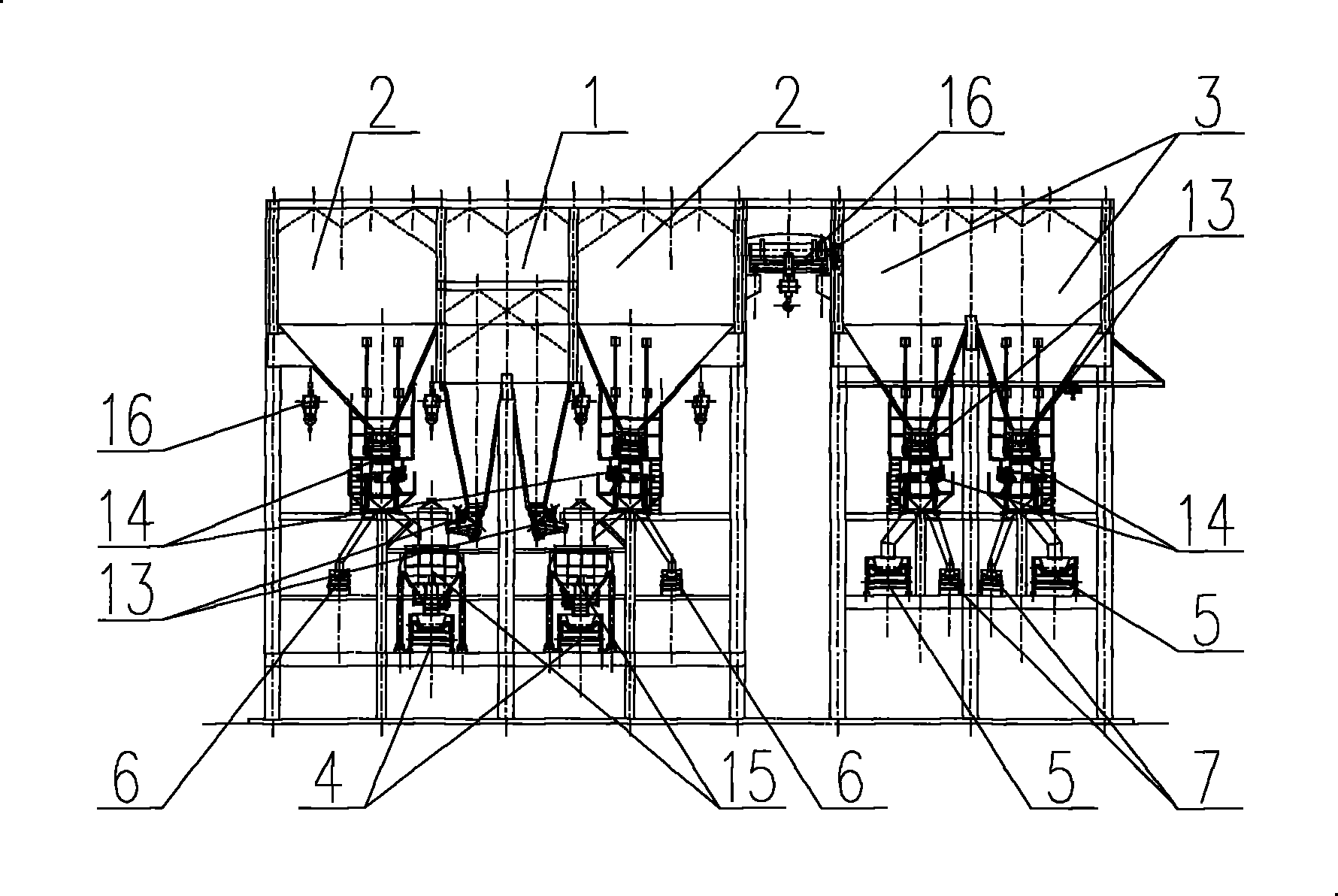

Combination technique arrangement of two coke and ore tank systems

ActiveCN101538625BLong storage timeCentralized controlBell-and-hopper arrangementPollutionMaterials science

The invention belongs to the technical field of metallurgical iron making, and discloses a combination technical arrangement of two coke and ore tank systems. The invention mainly comprises sintering ore tanks, a flux tank fine ore bin and a coke breaking bin facility, and is characterized in that: the coke tanks and mixed ore tanks of two blast furnaces are arranged in the way of one-to-one combination; the sintering ore tank of each blast furnace is independently arranged; and the mixed ore tanks and the sintering ore tanks are arranged in parallel in a one to one manner. The mixed ore tankis arranged between the sintering ore tanks. A feeding tape machine is arranged on the coke ore tank, and the lower part of the coke ore tank is provided with a feeding and screening plant, a weighing funnel, a feeding tape machine, an ore and coke returning tape machine and a dust-removal system, and is also provided with a transfer station required for transferring and storing crude fuel, a fine ore bin and a fine coke bin facility. The invention has compact technical arrangement, smaller occupation of area, small number of matched equipments, and lower engineering investment, saves time ofequipment maintenance and repairing, can easily and integrally control the pollution source such as dust, noise and the like, and is an ideal arrangement method of the coke and ore tank which is shared by two blast furnaces.

Owner:CISDI ENG CO LTD

Method for co-producing methyl isobutyl ketone and methyl isobutyl carbinol

ActiveCN103420786BLow costImprove stabilityOxygen-containing compound preparationOrganic compound preparationChemical industryHydrogen

The invention relates to a method for coproduction of methyl isobutyl ketone and methyl isobutyl carbinol, and particularly to the production method for simultaneously coproducing methyl isobutyl ketone and methyl isobutyl carbinol with acetone and hydrogen as raw materials, employing a non-pure noble metal catalyst especially employing a catalyst with a brand number of BC-A-61 and produced by Beijing Research Institute of Chemical Industry, and under reaction conditions of the reaction temperature of 170-230 DEG C, the reaction pressure of 1.0-6.0 MPa, the acetone liquid phase airspeed of 0.5-3.0 h<-1> and the hydrogen and ketone molar ratio of 0.3-1. The method of the invention has the advantages of relatively low catalyst cost, reasonable and simple technological process and low energy consumption, simultaneously coproduces two kinds of products which are methyl isobutyl ketone and methyl isobutyl carbinol and have supply and demand gaps existing in markets, and has few by-product heavy components.

Owner:ZHEJIANG XINHUA CHEM +1

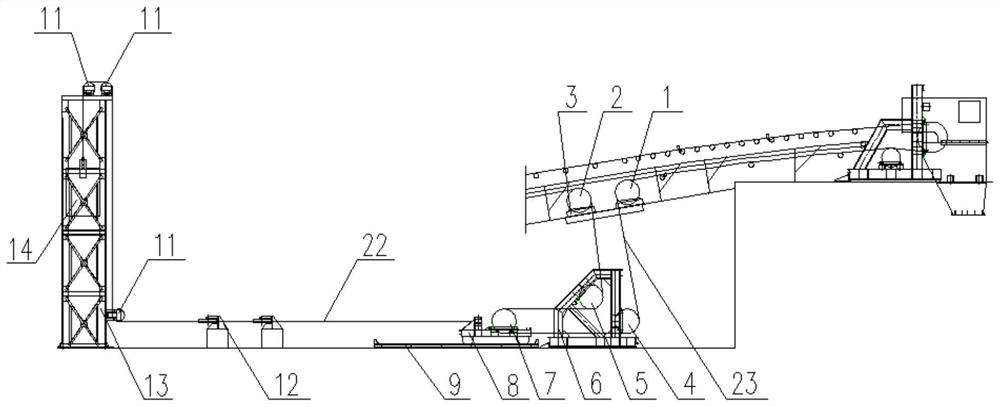

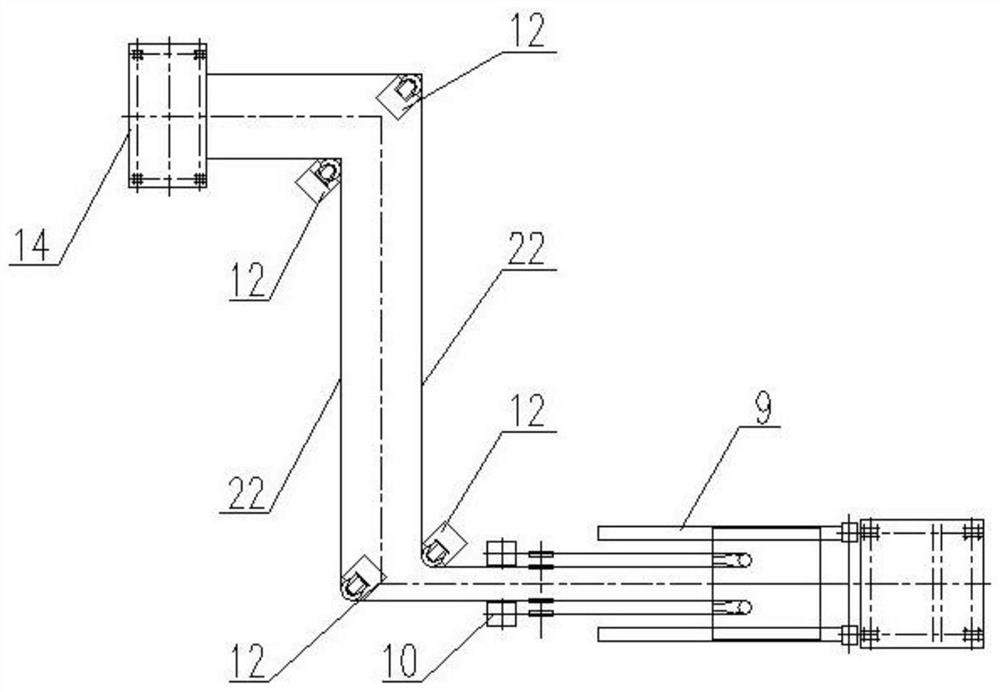

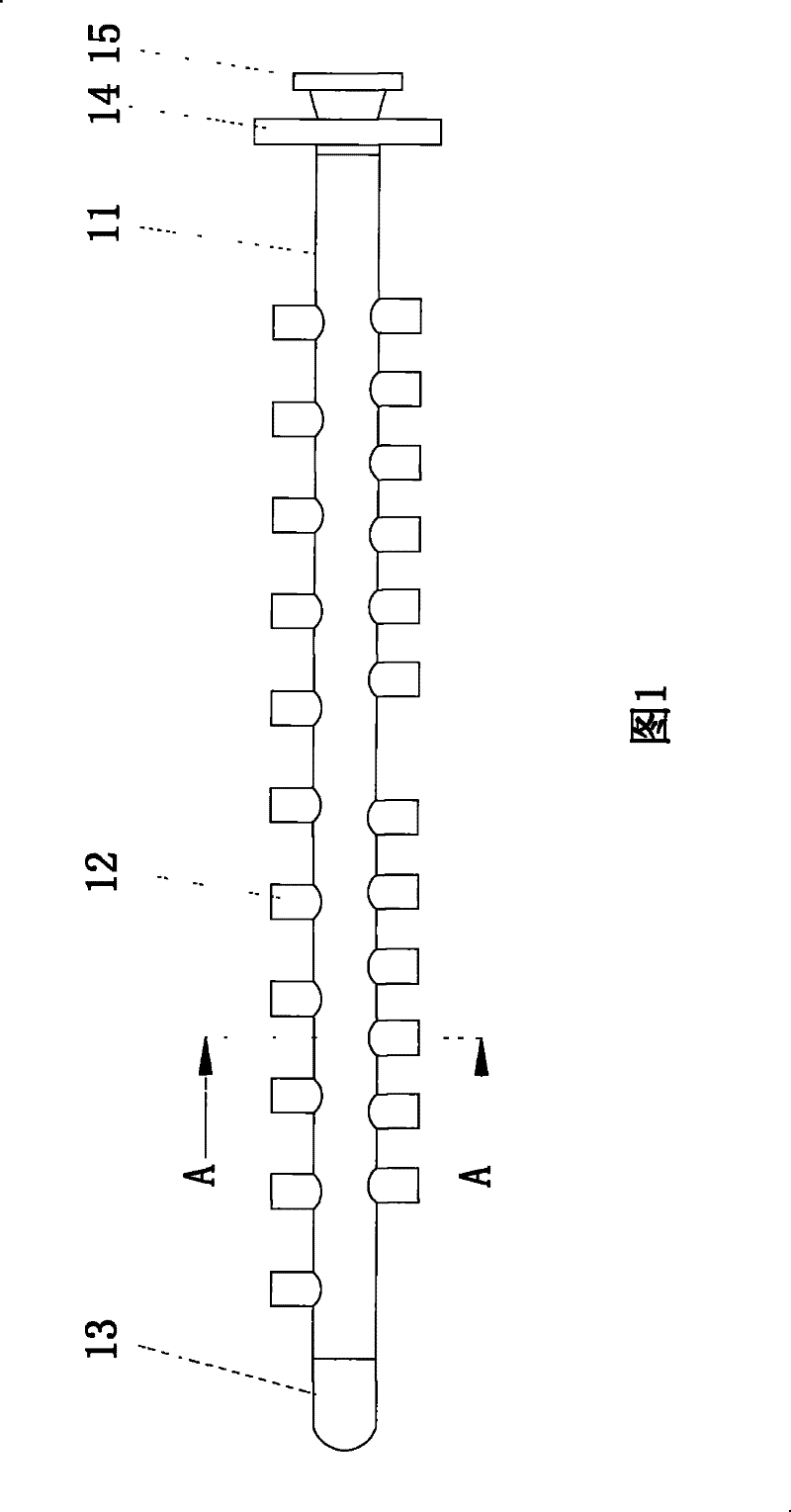

Belt tensioning device and method under height limited condition

PendingCN112607335ARealize tension workSimple structureConveyorsRollersClassical mechanicsBlock and tackle

The invention relates to a belt tensioning device and method under the height limited condition, and belongs to the technical field of belt type conveying. The belt tensioning device comprises a tensioning device, a stretching device and a rail (9). The tensioning device comprises a bend roller (1), a bend roller II (2), a roller support I (3), a bend roller (4), a bend roller (5), a roller support II (6), a bend roller (7) and a tensioning trolley (8). The stretching device comprises a pulley I (11), a pulley support (12), a tensioning tower (13), a heavy punch box (14) and a steel wire rope (22). According to the device, the tensioning device tower is arranged on one side of a belt conveyor through the bend rollers and pulley blocks, and under the condition that the height of a corridor cannot meet the requirement for the tensioning stroke of the heavy punch box, a belt is tensioned.

Owner:唐钢国际工程技术有限公司

A compact combined straightening equipment of a turning machine and a flattening machine

ActiveCN107020310BHigh precisionImprove work efficiencyMetal-working feeding devicesMetal working apparatusEngineeringAutomation

The invention provides plate overturning machine and flattening machine compact linkage type straightening equipment. The plate overturning machine and flattening machine compact linkage type straightening equipment comprises a machine front conveying roller bed (5), a plate length measuring device (4), a mechanical plate type detection device (1), a flattening machine (6) and a machine rear conveying roller bed (7), all of which are sequentially arranged in the advancing direction of a to-be-machined plate (2). The plate overturning machine and flattening machine compact linkage type straightening equipment further comprises a plate overturning machine (3) located on the left side or the right side of the machine front conveying roller bed (5), the plate overturning machine (3) can conduct face overturning on the to-be-machined plate (2) on the machine front conveying roller bed (5), and the mechanical plate type detection device (1) can make contact with the surface of the to-be-machined plate (2) so as to detect the plate type of the to-be-machined plate (2). According to the straightening equipment, the heavy work of traditional pure manual detection of the plate type surface quality can be completely abandoned; and the automation degree of a linkage unit is greatly improved, and the labor productivity is greatly improved.

Owner:CERI TECH +1

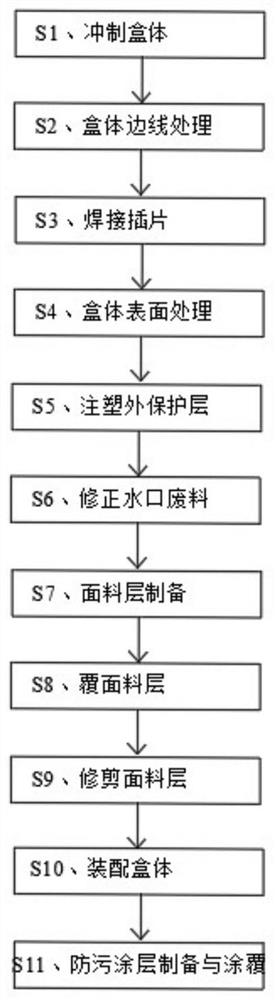

Preparation process of ram-type spectacle case

InactiveCN113412996AHigh strengthWith fall resistanceOther accessoriesPunchingUltimate tensile strength

The invention discloses a preparation process of a ram-type spectacle case. According to the technical scheme, the preparation process is characterized by comprising the following steps of: S1, punching of a case body: punching and drawing out a case body comprising an upper portion and a lower portion through a drawing die, and using a side punching die to punch holes in one side of the lower portion; S2, side line treatment on the case body: deburring the punching side lines of the case body; S3, welding of inserts: welding elastic clamping pieces matched with the punched holes in the lower portion to one side of the upper portion; S4, surface treatment on the case body: carrying out surface treatment on the surface of the case body; S5, injection molding of an outer protection layer: placing the case body in an injection mold, and injecting a layer of resin material on the surface of the case body in a coating manner; S6, correction of waste at a water gap: removing waste at an injection molding water gap; S7, preparation of a fabric layer; S8, covering of the fabric layer; and S9, trimming of the fabric layer. The spectacle case prepared by the preparation process of a ram-type spectacle case has the advantages of high strength, drop resistance, difficulty in damage, long service life, difficulty in dirt accumulation and the like.

Owner:ANHUI YIXUAN METAL SCI & TECH CO LTD

Method for treating poly butylene succinate production waste water by biochemical method

ActiveCN103073156BGuaranteed emission standardsSimple processMultistage water/sewage treatmentWater volumeAluminium chlorohydrate

Owner:北京众质环保科技有限公司

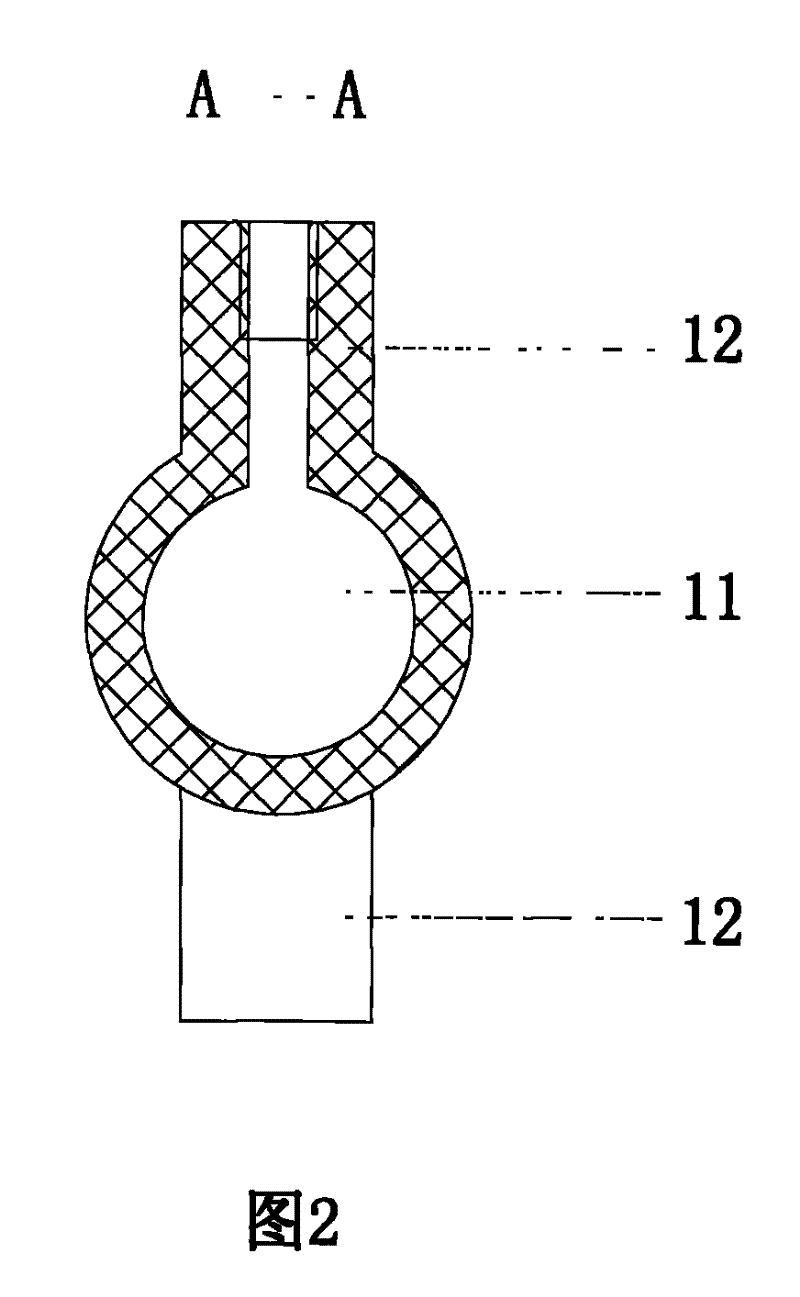

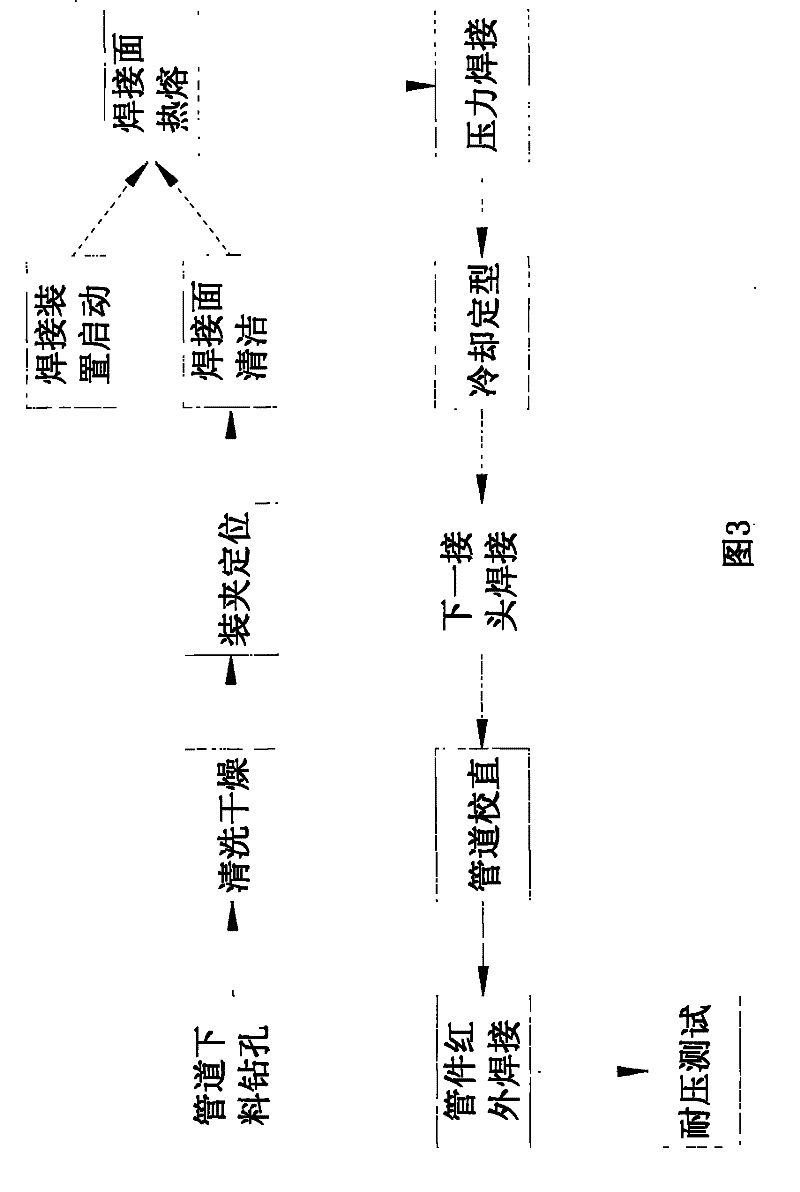

Thyristor group valve acaleph matched main tube and manufacturing technology

ActiveCN101494206BEnsure consistencyHigh strengthSemiconductor/solid-state device detailsSolid-state devicesManufacturing technologyStructural engineering

The invention discloses a main distribution pipe of a thyristor valve group and a production method thereof, comprising a pipe. A pipe plug is arranged on one end of the pipe; a flange and a flange connector are arranged on the other end of the pipe; a plurality of distribution nuts are arranged on the pipe; the pipe, the pipe plug, the flange, the flange connector and the distribution nuts are all made of PPH or PVDF material; the pipe is welded to the distribution nuts in a hot-melt pressure welding mode; the flange, the flange connector and the pipe plug are welded to the distribution nuts in an infrared welding mode; the distribution nuts are integrated with the pipe as one through pressure heat welding. The welding mechanical strength and pressure resistance grade are high; such parameters as welding temperature, time and pressure are controlled mechanically and human factors involved are few, thus guaranteeing the uniformity of the performance of all craters. The main distribution pipe of the thyristor valve group and the production method thereof have reasonable working procedure arrangement, thereby increasing the yield rate of products.

Owner:岳阳高澜节能装备制造有限公司

Processing system and method for compatible processing of natural material gravel and artificial hard rock and gravel

ActiveCN103752393BAdapt to feature requirementsMeet the maximum load requirementsGrain treatmentsArtificial materialsComputer science

The invention discloses a processing system and a processing method for compatible processing of a natural material gravel and artificial hard rock and gravel. The processing system comprises a stock bin, wherein a coarse crushing device is arranged below the stock bin, and matched with a first screening device; a medium crushing device is arranged behind the first screening device and matched with a second screening device; an ultra-crushing device is arranged behind the second screening device and matched with a third screening device; a rod mill is also arranged inside the processing system. By adopting the system and the method, two independent single-material source gravel systems, namely a land natural material gravel system and an artificial hard rock and gravel system are merged into a hard rock and gravel system and a natural material processing system, and can be compatible to treatment of two gravel materials. Staged production is adopted in a production form; screening equipment is designed according to the natural material when processing equipment is prepared, the crushing equipment is designed according to an artificial material, the maximal load demands are met, and flexible adjustment is carried out through a sealing-tape machine and a slide chute in the staged production, so as to adapt to the requirements of characteristics of different material sources.

Owner:CHINA GEZHOUBA GROUP NO 5 ENG

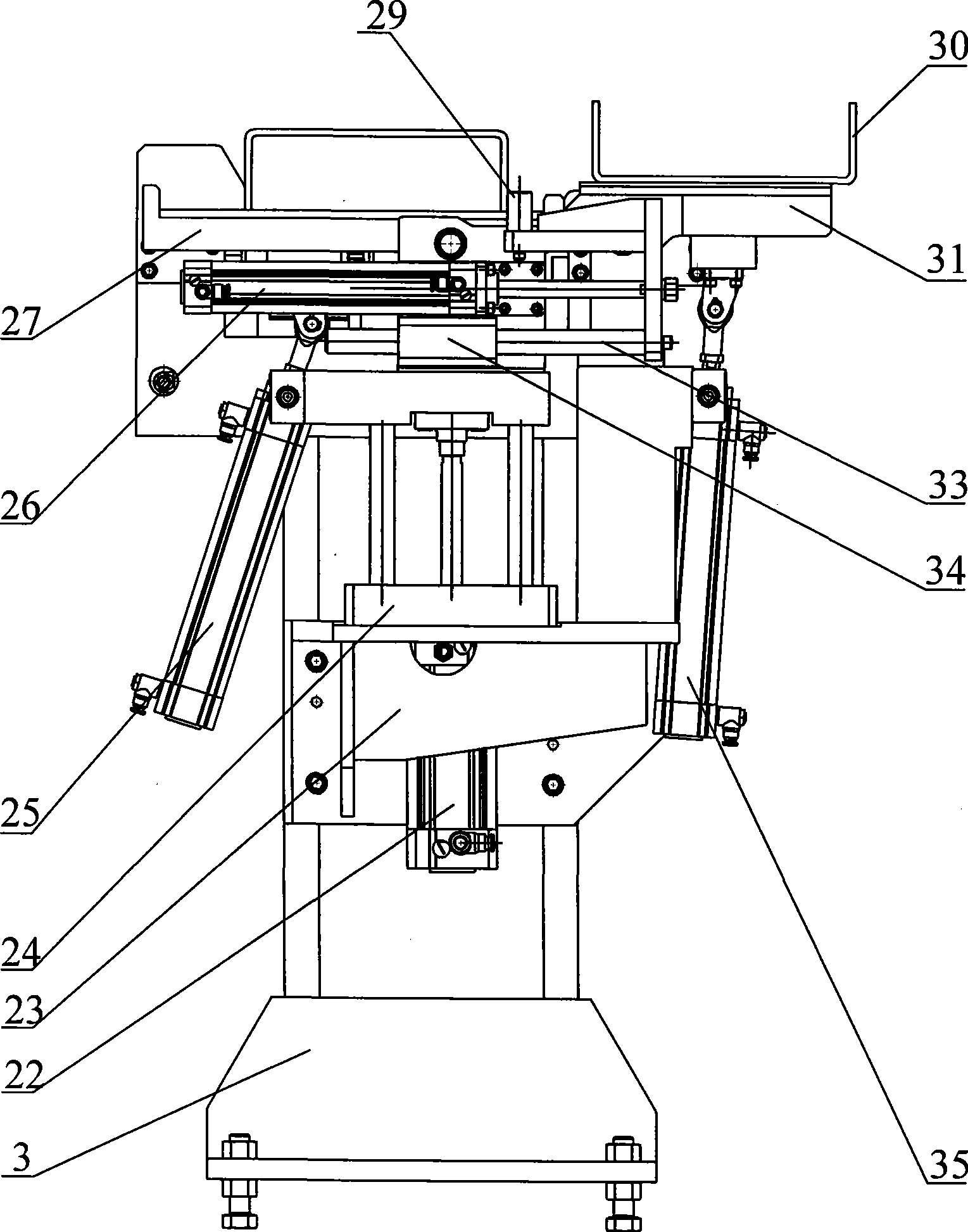

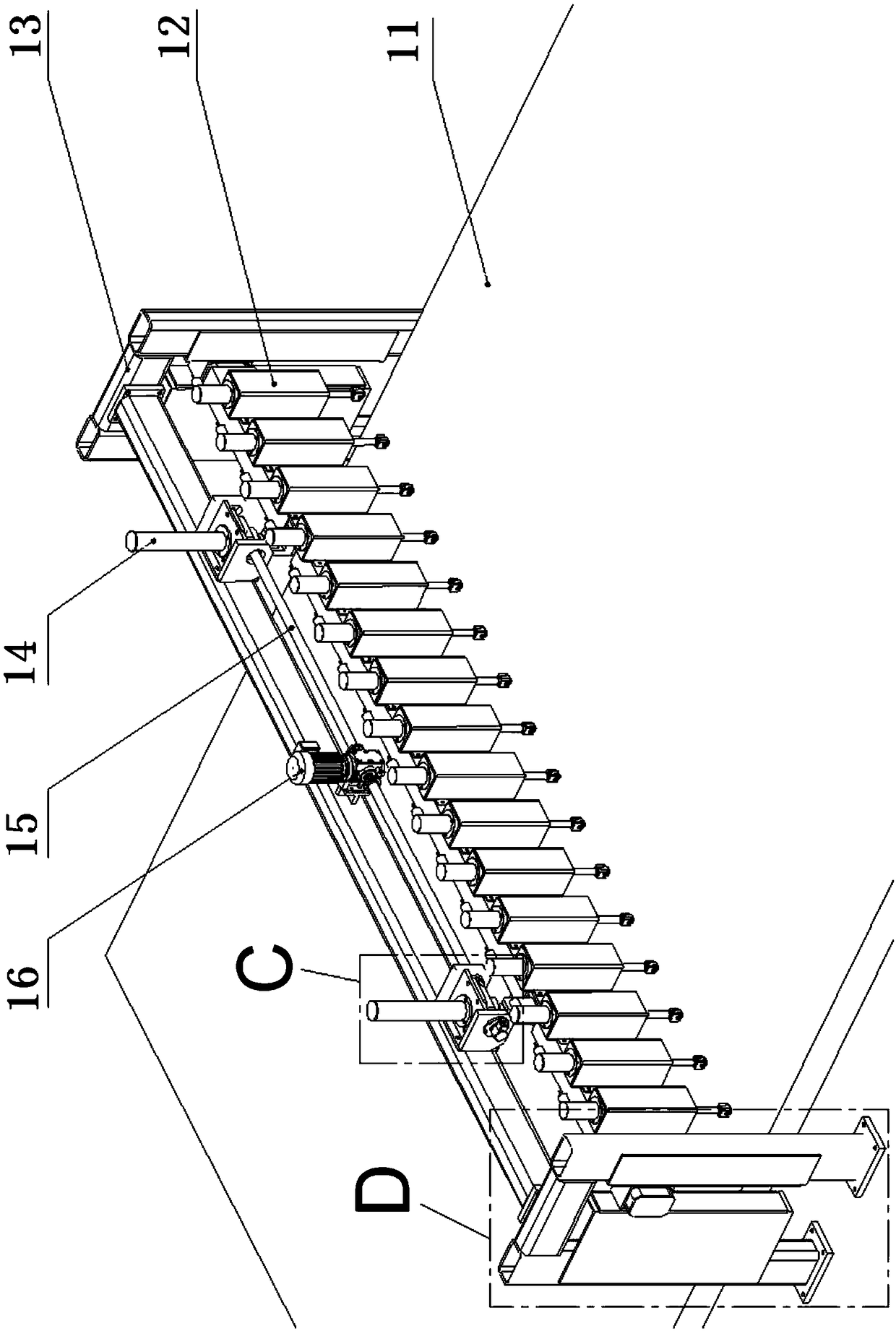

Production device and machining method for U-shaped longitudinal beam and lining beam automatic positioning beam combining spot welding

ActiveCN103317248BImprove the operating environmentSimple processWelding/cutting auxillary devicesAuxillary welding devicesStringerEngineering

The invention relates to a production device and a machining method for U-shaped longitudinal beam and lining beam automatic positioning beam combining spot welding. The production device and the machining method are characterized in that a beam combining feedstock feeding device is placed on the right side of an automatic spot welding device, a lining beam end face positioning component is placed on the front side of the beam combining feedstock feeding device, six sets of longitudinal beam feeding devices are sequentially arranged on the right side of the beam combining feedstock feeding device and the right side of the lining beam end face positioning component, and a feeding platform is placed in front of the longitudinal beam feeding devices. A feedstock extraction device is placed at back of the longitudinal beam feeding devices, and a track installed in the feedstock extraction device forwards extends to reach the position above the feeding platform. A beam combining discharged material feeding device and two sets of discharged material supporting rollers are sequentially placed on the left side of the automatic spot welding device. A discharging platform is placed in front of the beam combining discharged material feeding device and the discharged material supporting rollers, a discharged material extraction device is placed at back of the beam combining discharged material feeding device and the discharged material supporting rollers, and a track installed in the discharged material extraction device forwards extends to reach the position above the discharging platform.

Owner:广州市力鼎汽车零部件有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com