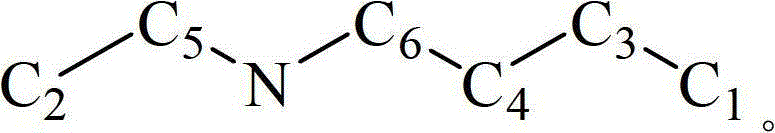

The production method of n-ethyl n-butylamine

A technology of ethyl n-butylamine and its production method, which is applied in chemical instruments and methods, preparation of amino compounds, preparation of organic compounds, etc., which can solve problems such as equipment manufacturing troubles and industrial scale-up difficulties, and achieve low use cost and low cost , The effect of reasonable technological process layout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

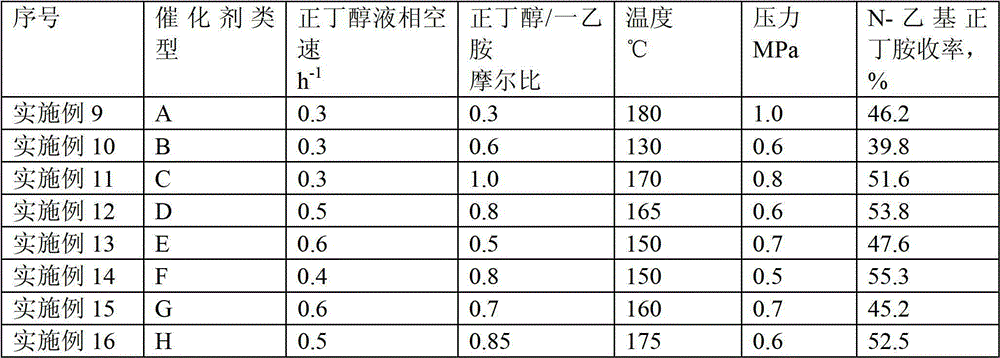

Embodiment 1

[0031] The mixed solution of γ-alumina modified by MgO and a certain proportion of copper nitrate, cobalt nitrate, and lanthanum nitrate is fully impregnated, dried at room temperature and then dried at 120°C for 5 hours, then roasted at 400-550°C for 8 hours, and cooled naturally. Obtain the required supported catalyst A, wherein the weight content of each active component is: Cu20%, Co10%, La1.5%, Ce1.5%.

Embodiment 2

[0033] As in Example 1, the obtained active component content is Cu18%, Zn6%, Fe7%, La1%, Ce1% (weight) catalyst B.

Embodiment 3

[0035] Obtaining active component content as embodiment 1 is Cu16%, Co8%, Fe5%, La1%, the catalyst C of Ce0.2% (weight).

[0036] Example 3

[0037] Obtaining active component content as embodiment 1 is Cu12%, Co9%, Zn5%, La1%, the catalyst D of Ce1.5% (weight).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com