Belt tensioning device and method under height limited condition

A tensioning device and tensioning device technology, which is applied to conveyor objects, transportation and packaging, conveyors, etc., can solve the problem of limited layout, inability to achieve belt tensioning, and corridor height that cannot meet the tension of heavy hammer boxes. problems such as travel, to achieve the effects of low cost, convenient installation and simple device structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

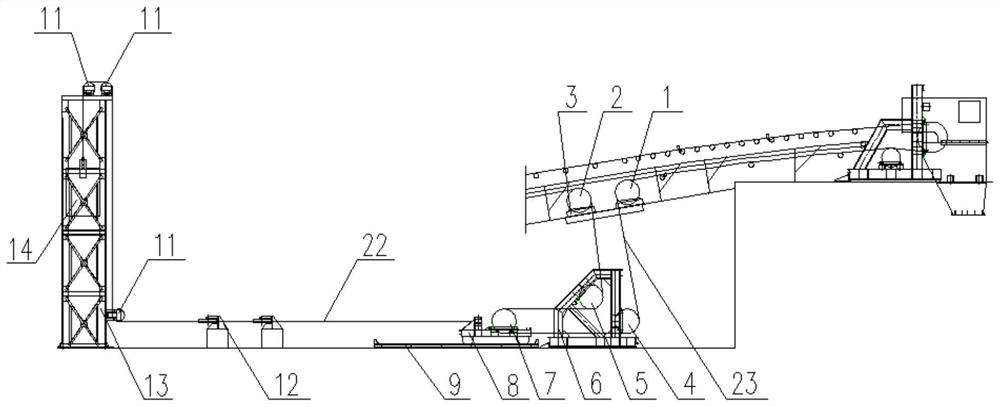

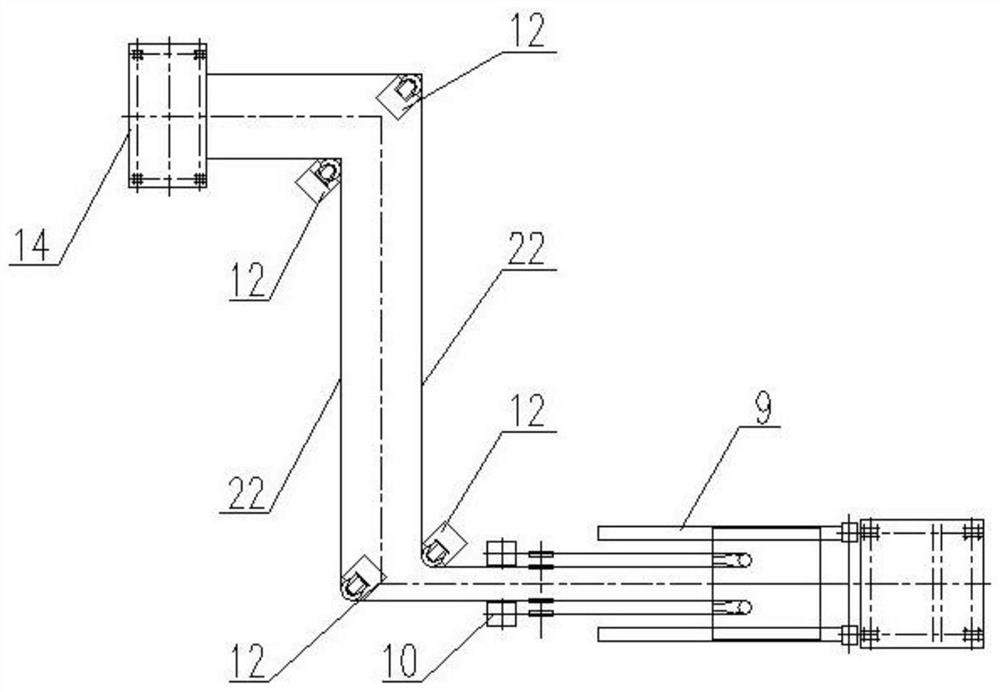

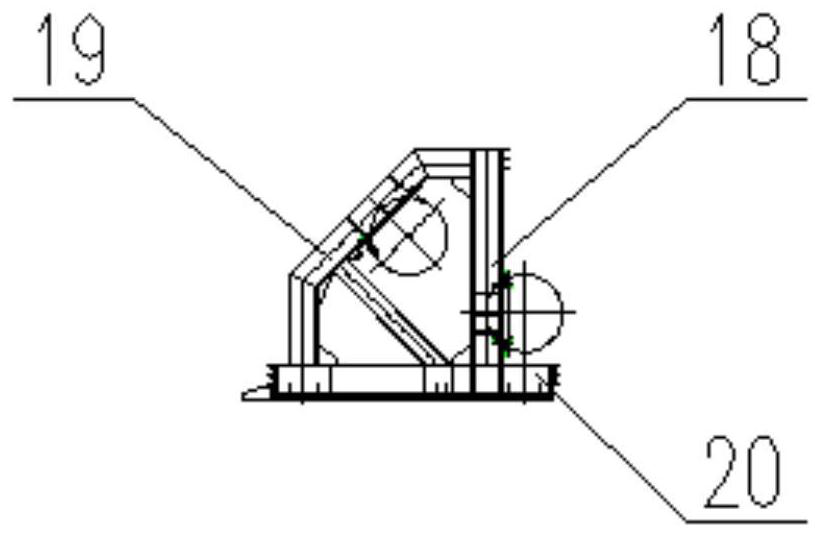

[0025] As shown in the accompanying drawings, a belt tensioning device under a height-restricted condition includes a tensioning device, a stretching device, and a track 9, and the tensioning device includes a reversing roller 1. Reversing roller Ⅱ 2, roller support Ⅰ 3, reversing roller 4. Reversing roller 5. Roller bracket Ⅱ 6. Reversing roller 7. The tensioning trolley 8, the tensioning trolley 8 includes wheels 16 and a frame 17, the four wheels 16 are assembled under the frame 17, the wheels 16 are matched with the track 9, and the roller support I3 is steel Structural device, the redirecting roller 1. The reversing roller II2 is respectively assembled on two roller supports I3, and the two roller supports I3 are assembled on the lower side of the down belt 23, and the roller support II6 is a steel structure, including vertical beams 18 and inclined beams 19 , the bottom beam 20, the vertical beam 18 is fixedly connected to the bottom beam 20, the inclined beam 19...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com