Thyristor group valve acaleph matched main tube and manufacturing technology

A thyristor valve and manufacturing process technology, applied in the direction of pipes/pipe joints/pipes, pipes, branch pipelines, etc., can solve the problems of low welding strength, short service life, easy bending and deformation of pipes, etc., and achieve welding mechanical strength and The effect of high withstand voltage level, guaranteed performance consistency, and reasonable process layout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

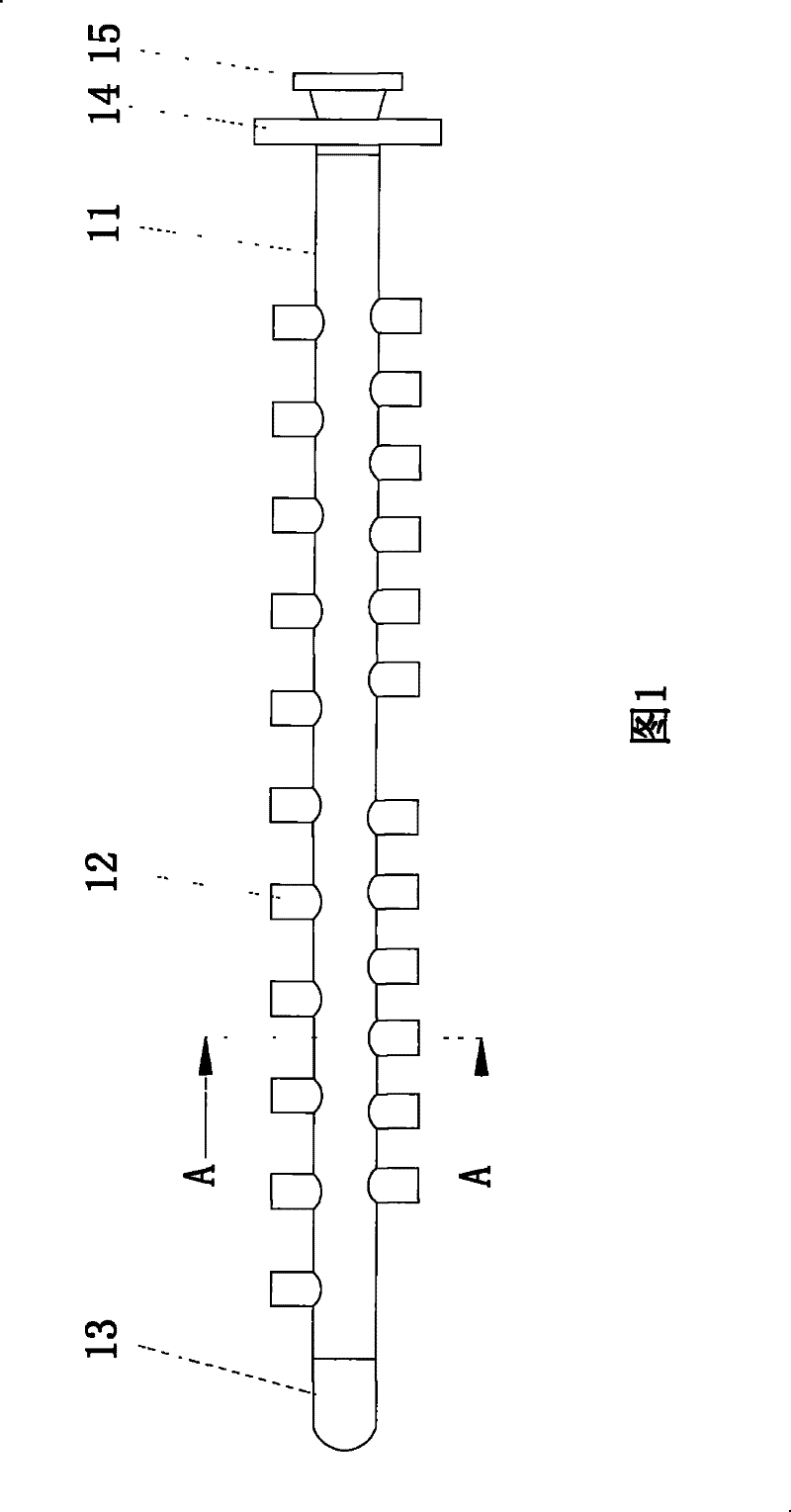

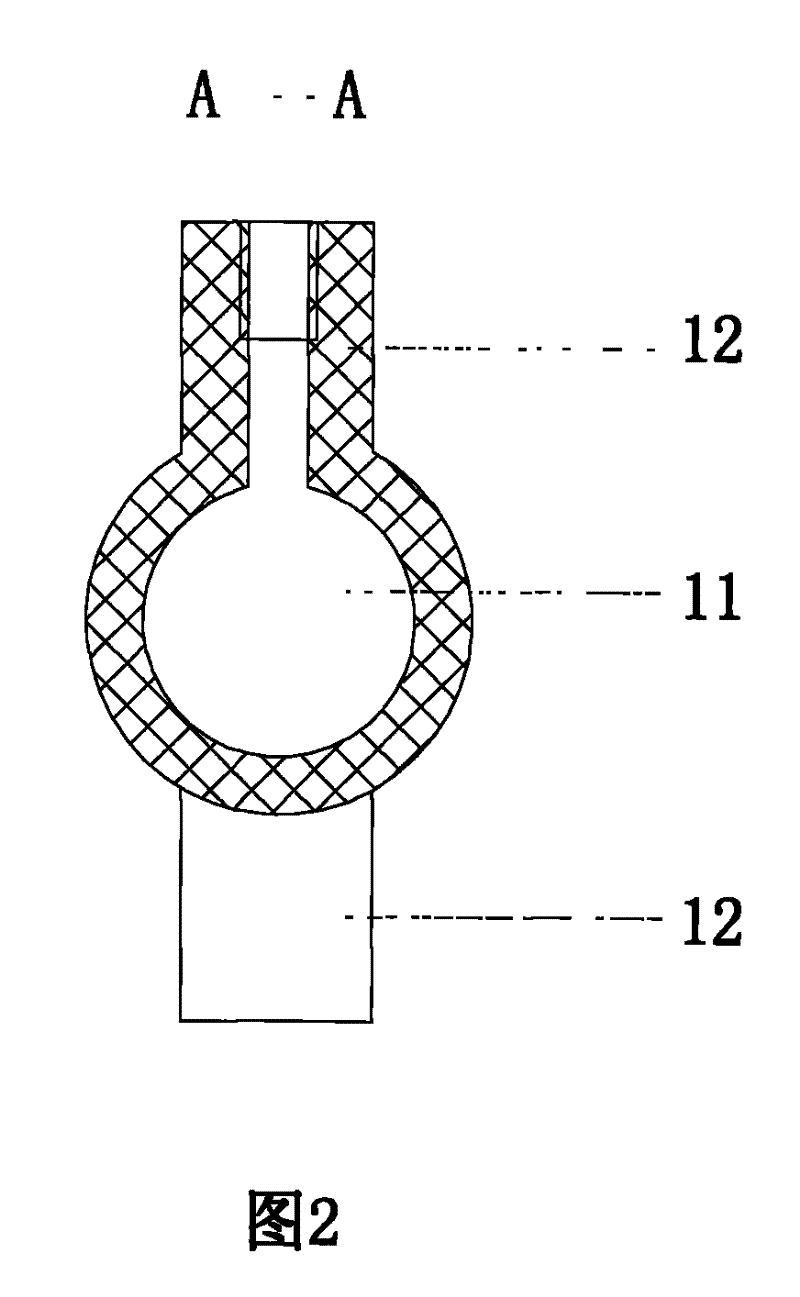

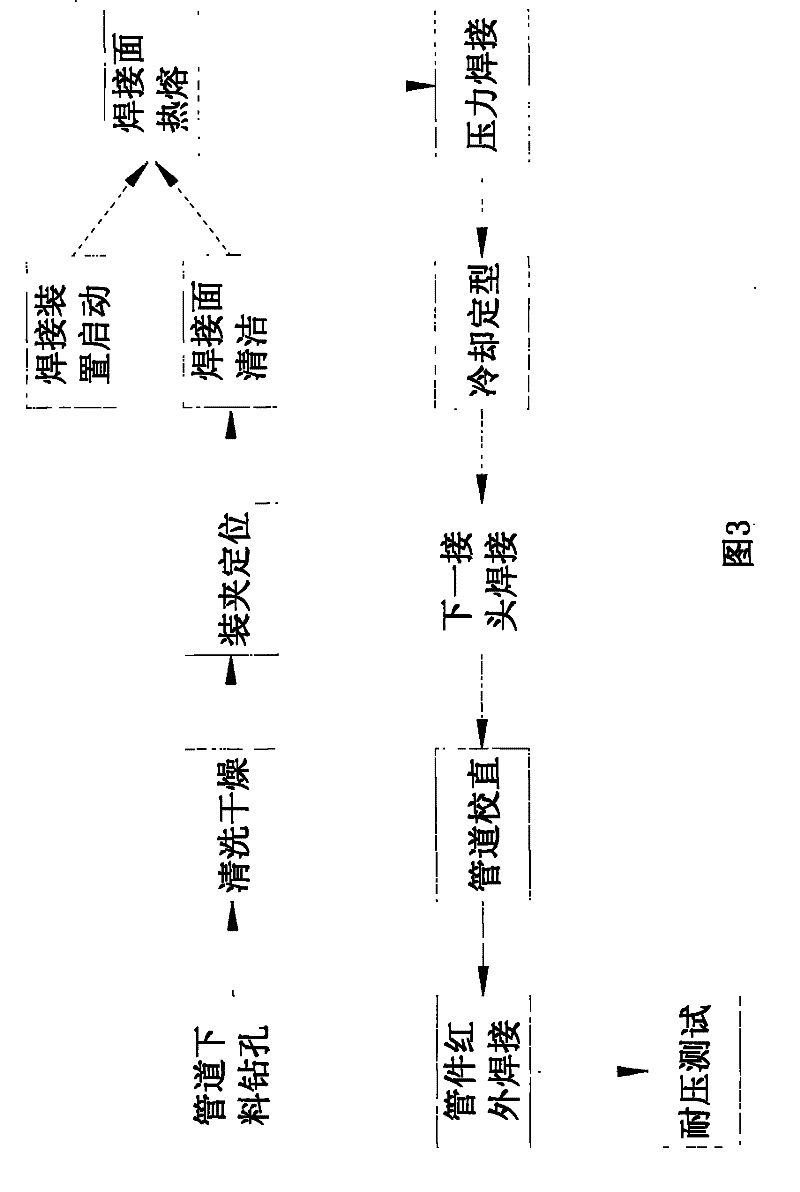

[0026] With reference to Fig. 1, Fig. 2, a kind of thyristor valve group is equipped with jellyfish tube, comprises pipeline 11, and one end of pipeline 11 is provided with pipe plug 13, and the other end is provided with flange 14 and flange connector 15, and pipeline 11 is provided with several The water distribution nut 12, the pipe 11, the pipe plug 13, the flange 14, the flange connector 15 and the water distribution nut 12 are all made of PPH or PVDF, and the pipe 11 is welded on the water distribution nut 12 by hot-melt pressure welding , the flange 14, the flange connector 15 and the pipe plug 13 are welded on the water distribution nut 12 by infrared welding, and the water distribution nut and the pipeline are pressure welded into one body, the welding mechanical strength and pressure resistance level are high, and the welding temperature, time, Parameters such as pressure are mechanically controlled, with few human factors, ensuring the consistency of performance of a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com