Rechargeable handheld electric spray gun

A rechargeable, electric technology, applied in the direction of spraying devices, liquid spraying devices, etc., can solve the problems of affecting product quality, complex heat dissipation structure, inconvenient use, etc., and achieve the effects of reducing production costs, low noise, and preventing deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

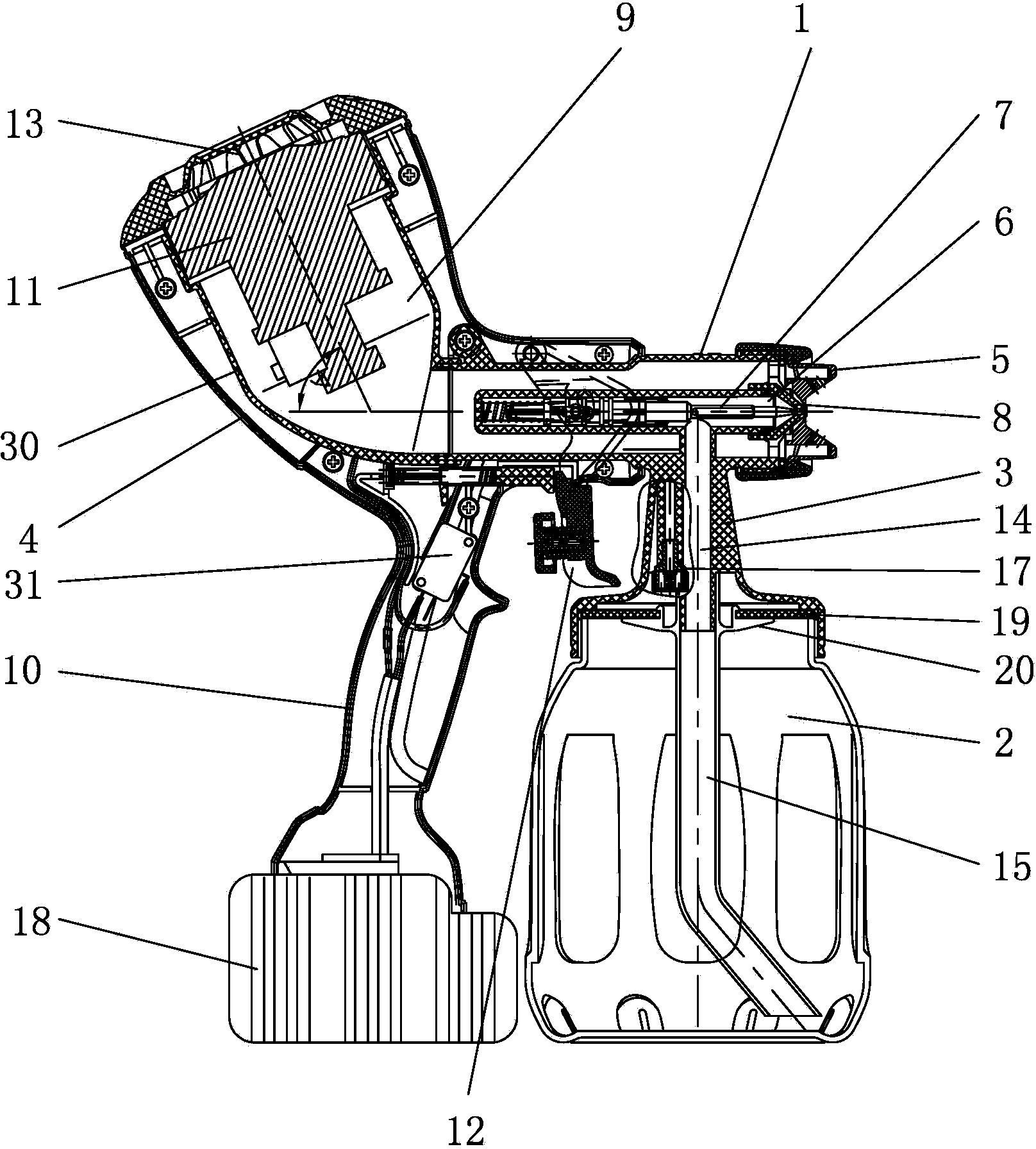

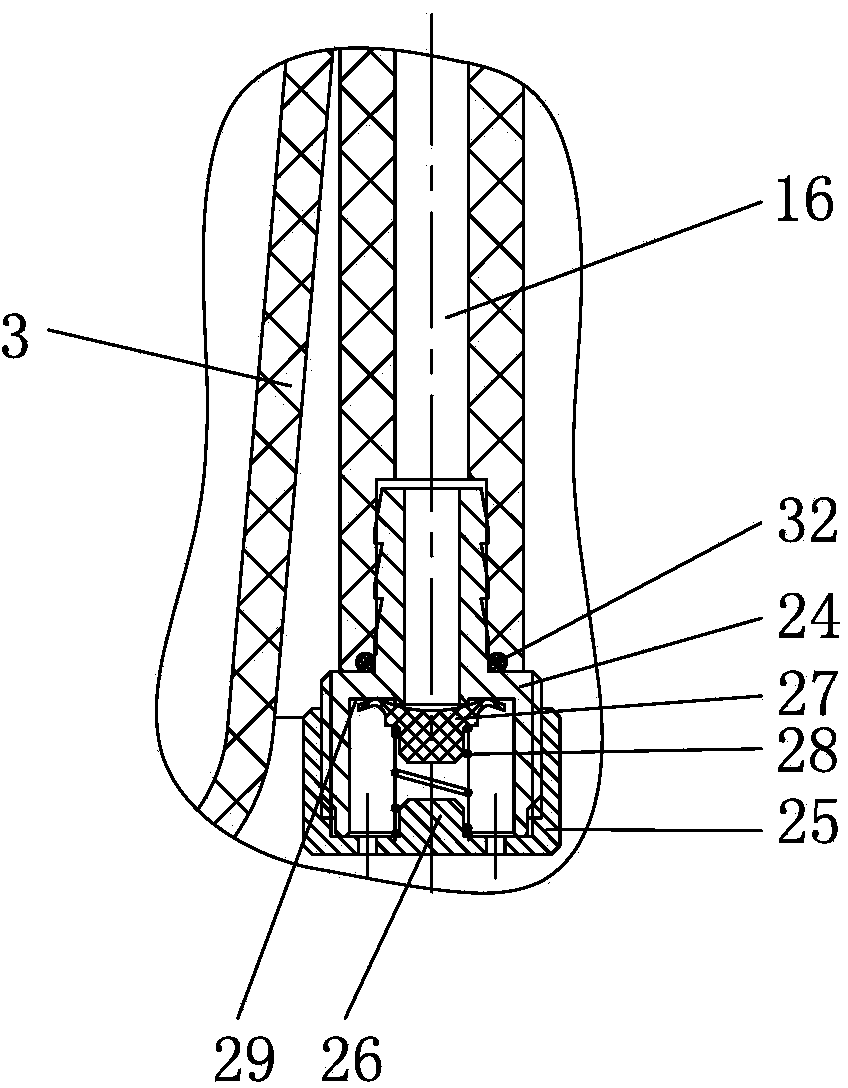

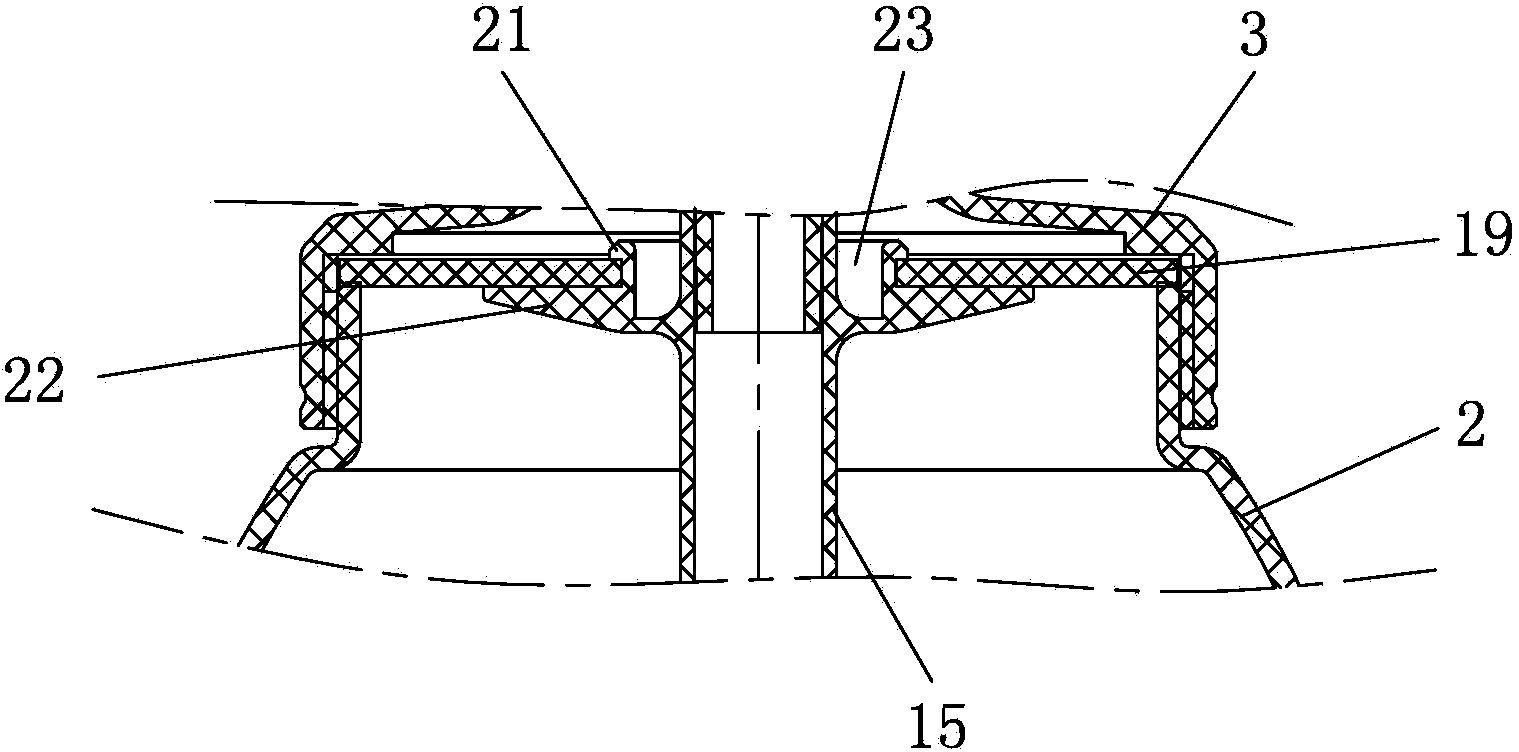

[0025] The present invention will be further described below with specific embodiments in conjunction with the drawings, see figure 1 —3:

[0026] A rechargeable hand-held electric spray gun includes a gun body 1, a material tank 2, a base 3 connecting the gun body 1 and the material tank 2, and a housing 4, and the gun body 1 and the base 3 are an integrated structure. The front end of the gun body 1 is provided with an airflow nozzle 5, the gun body 1 is provided with a needle plug installation cavity 6, the needle plug 7 is arranged in the needle plug installation cavity 6, and the front end of the needle plug installation cavity 6 is provided with a material nozzle 8, a needle plug 7. One end of the gun body is set in the material nozzle 8. The upper part of the housing 4 is formed with an air chamber 9 and the lower part of the housing 4 is formed with a handle 10, the air chamber 9 is connected with the gun body in one communication, and the air chamber 9 is provided There ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap