Device and method for precoating fastening bolt with lubricant

A technology of pre-applying lubricant and fastening bolts, which is applied to the device, coating, digital control and other directions of coating liquid on the surface, which can solve the problems of stiff fingers, low production efficiency, not easy work, etc., and achieve convenient operation Simple, improve work efficiency and reduce labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

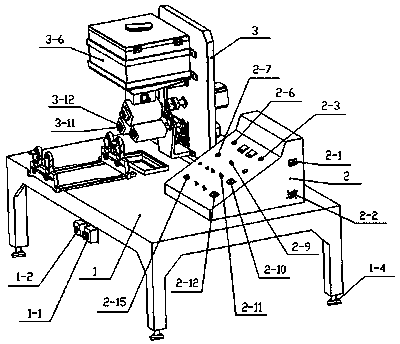

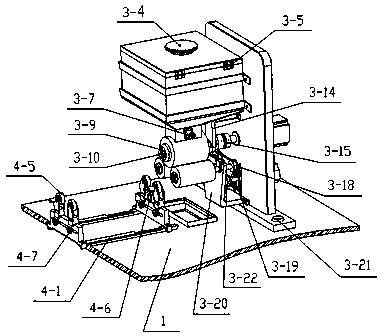

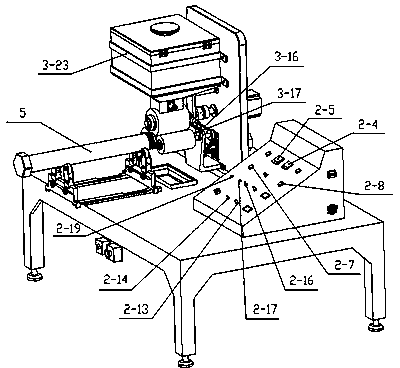

[0045] The present invention improves the method of manually applying lubricant to the fastening bolts when making up for the assembly of the fastening bolts used in the mechanical parts of the current wind power generating set, and uses the electromechanical transmission device to drive the brush roller to replace the manual hand-held paint brush to apply lubricant to the bolts. apply. It is a technical scheme of pre-applying lubricant device for fastening bolts. Its structure includes a workbench 1, a coating transmission mechanism, a bolt placement mechanism and a control box 2. Apply lubricant to meet the technical requirements of thread pre-applying lubricant.

[0046] Firstly, a workbench 1 is designed, and the coating transmission mechanism, bolt placement mechanism and control box 2 are fixed on the panel of the workbench 1. The workbench 1 is made of industrial aluminum material. The advantage of this material is that it is light in weight and easy to work. Four fixe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com