CIP-SIP (cleaning in place-sterilizing in place) system for bottle cleaning machine

A CIP-SIP, bottle washing machine technology, applied in the field of packaging, can solve problems such as troublesome operation, cumbersome work, secondary pollution, etc., and achieve the effect of avoiding potential risks and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

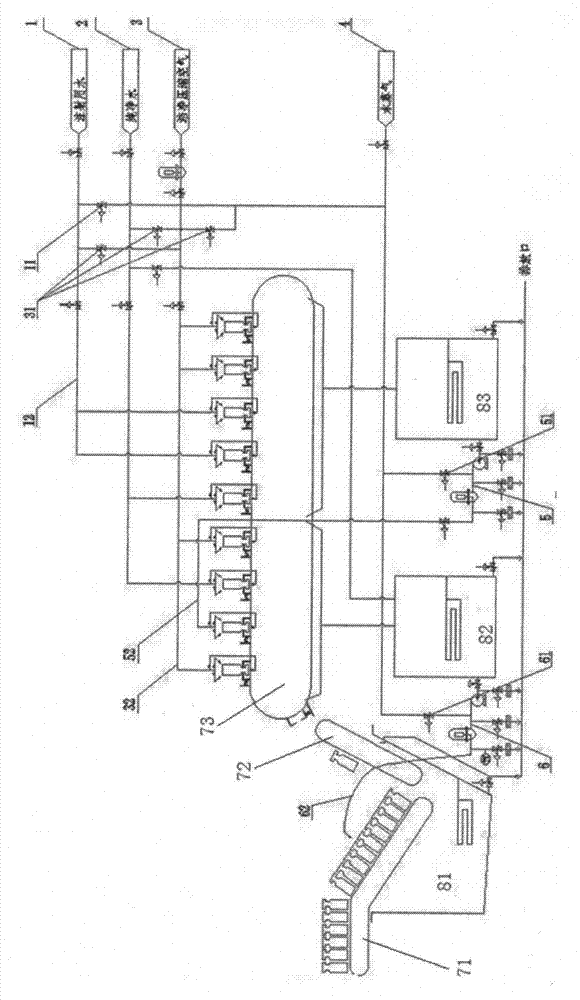

[0016] Such as figure 1 As shown, it is a schematic diagram of the CIP-SIP system process for bottle washing machines. The CIP-SIP system for bottle washing machines includes injection water cleaning process pipeline 1, pure water cleaning process pipeline 2, clean air blowing process Pipeline 3, steam sterilization process pipeline 4, circulating water cleaning process pipeline 5 and ultrasonic pre-injection water process pipeline 6. The container bottles pass through the first transportation assembly 71, the second transportation assembly 72 and the third transportation assembly 73 in sequence, at least a part of the first transportation assembly 71 is arranged in the first water tank 81, and the second transportation assembly 72 is arranged between the first transportation assembly 71 and the third transportation assembly 73. Between the third transportation component 73, when the container bottle is on the first transportation component 71, the ultrasonic pre-injection wat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com