Auxiliary stripping mechanism in continuous die

A technology of in-mold and material removal, applied in the direction of launching equipment, etc., can solve problems such as hidden safety hazards, risk of mold explosion, poor stability of material removal structure, etc., and achieve the effect of reasonable design, safe continuous production and simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

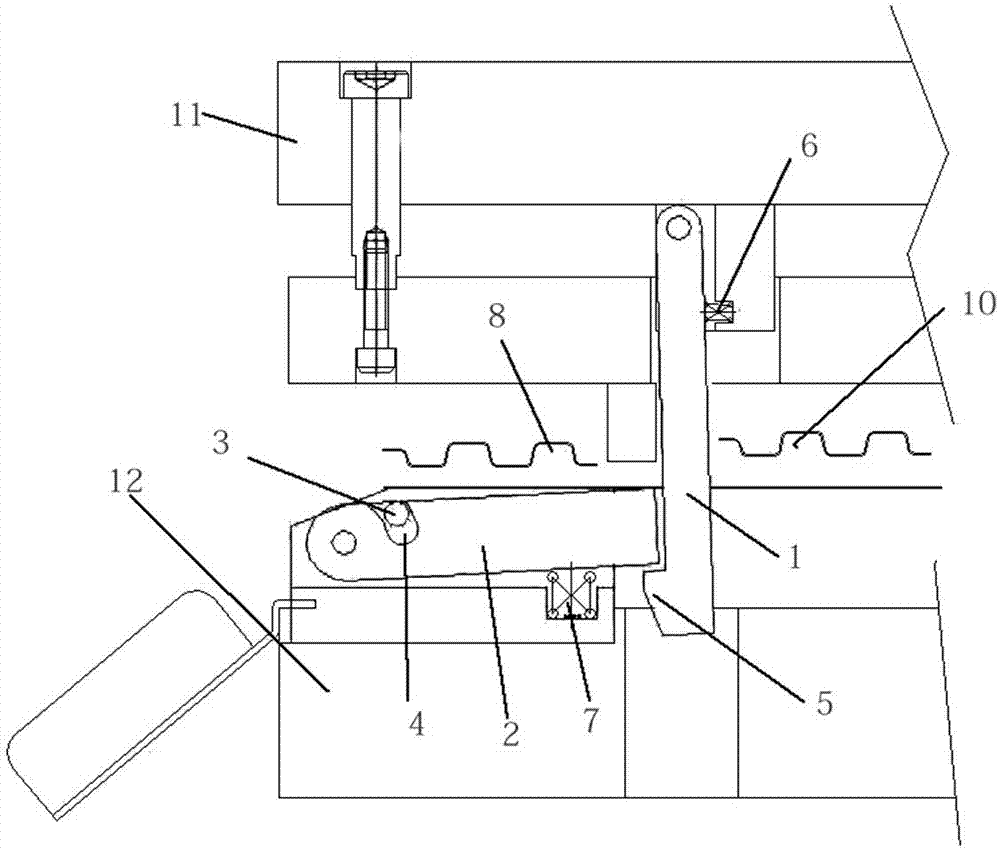

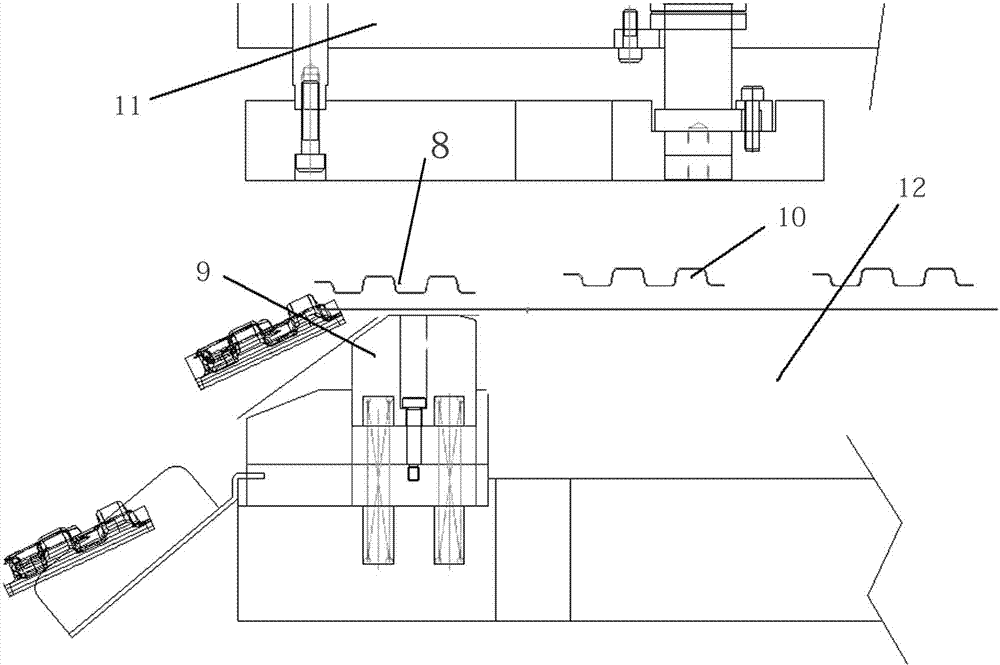

[0038] Such as figure 2 As shown, the present invention includes a swing rod 1, a stripping rod 2, and a limit post 3, and the upper end of the swing rod 1 is vertically installed in the upper template 11 of the continuous mold through a rotating shaft; the swing rod 1 is in the upper template 11 It can freely swing at an angle; the swing rod 11 is inserted into the lower template 12; the upper part of the swing rod 1 contacts and cooperates with a swing rod return spring 6 fixed in the upper template 11; the lower end of the swing rod 1 extends laterally A protrusion 5 with a straight side bevel forms a right-angle hook with the swing rod 1; the tail end of the stripping rod 2 is installed in the lower template 12 of the continuous mold through a rotating shaft, so that the stripping rod 2 is placed horizontally In the lower template 12; the other end of the stripping rod 2 can freely rotate upwards along the rotating shaft; the lower surface of the stripping rod 2 is in con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com