Machining method of worm gear with straight profile helical surface

A processing method and technology of helical surface, applied in worm gears, belts/chains/gears, elements with teeth, etc., can solve the problems affecting popularization and application, the difficulty of precision plane worm gears, etc., and achieve high precision and simple processing methods. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with the drawings and embodiments:

[0035] A method for processing straight-profile helical worm gears includes the following steps:

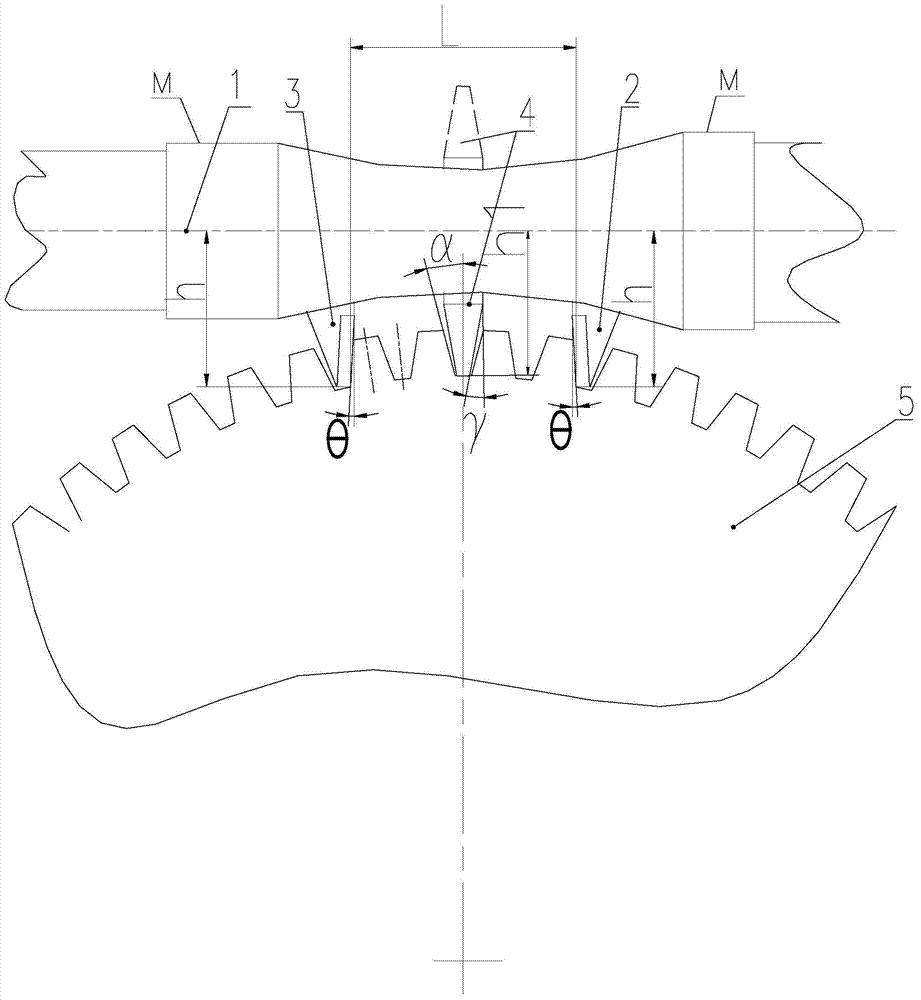

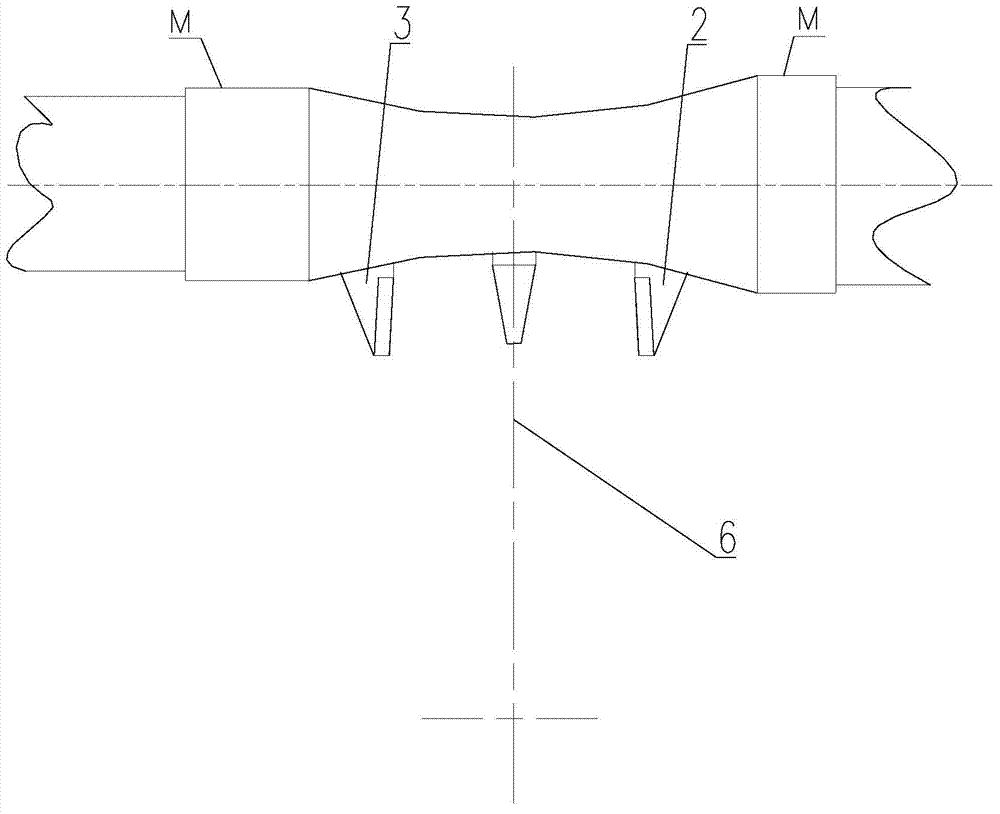

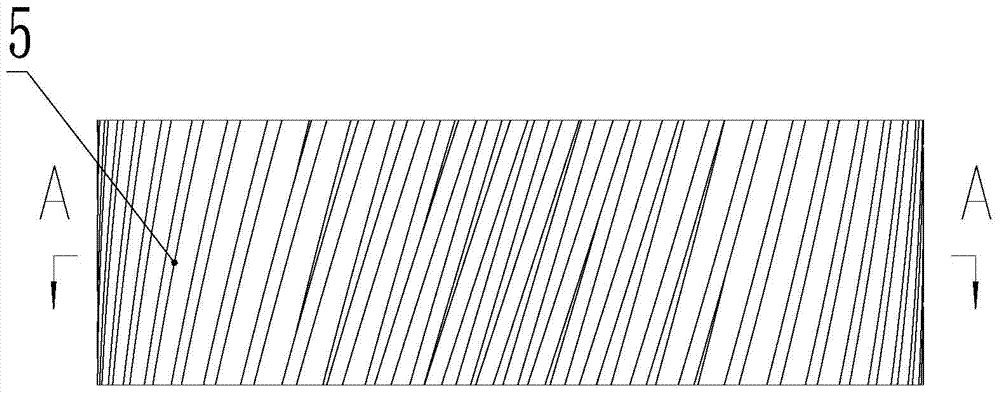

[0036] 1) Install the flying knife, such as figure 1 Shown:

[0037] Fix the right-toothed flying knife 2 and the left-toothed flying knife 3 on the fly-knife arbor 1 with a screw interval; connect the fly-knife arbor 1 to the machine tool holder; among them, the inclination angle of the left and right-toothed flying knife , Tool nose distance L and tool extension length h are determined according to the following formula:

[0038] θ=α-180×n / z;

[0039] L=2×R f ×sin((n-0.5)×180 / z);

[0040] h=a-R f ×cos((n-0.5)×180 / z);

[0041] Among them, α is the tooth profile angle of the machined worm gear;

[0042] z is the number of teeth of the worm gear to be processed;

[0043] Rf is the diameter of the tooth root circle of the machined worm wheel;

[0044] n is the number of worm gear teet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com