Modular flexible connection device allowing dynamic adjustment of stiffness

A flexible connection and dynamic adjustment technology, applied in the direction of manipulators, manufacturing tools, etc., can solve problems that cannot meet the needs of the market, and achieve the effect of compact structure design, small size, and meeting installation requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in further detail below in conjunction with accompanying drawing:

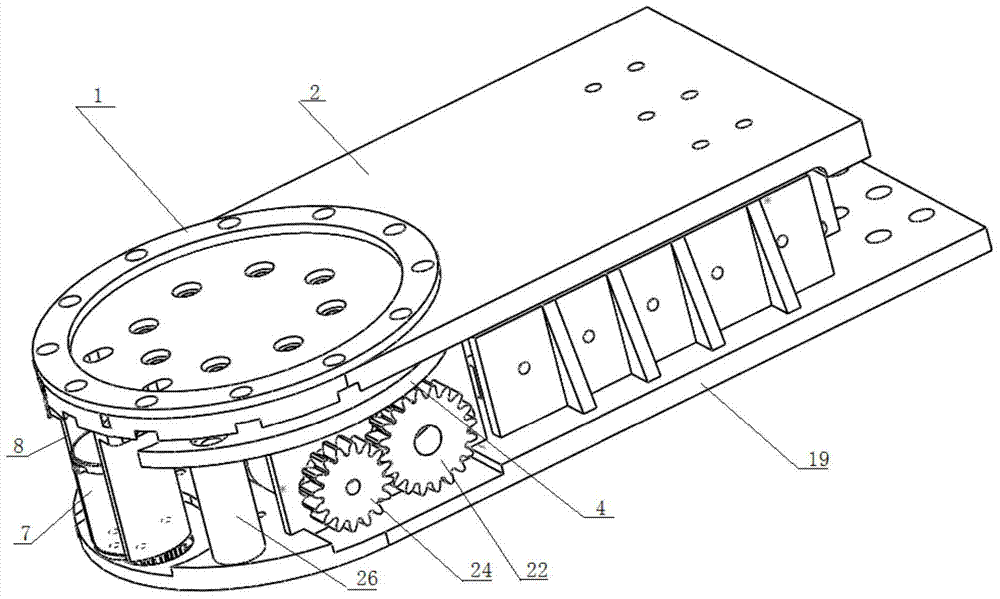

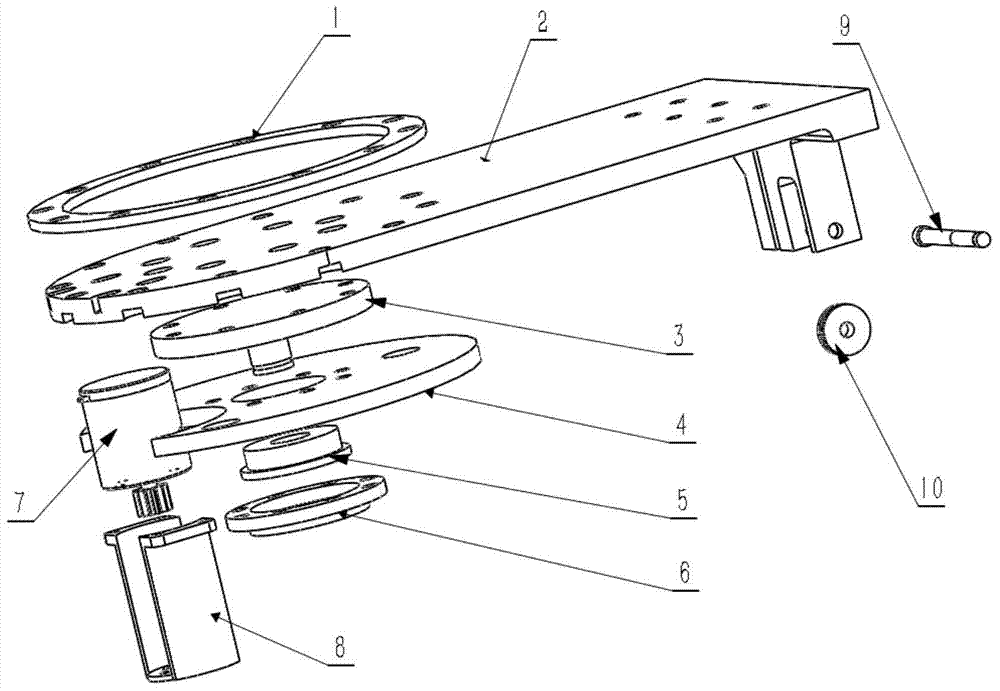

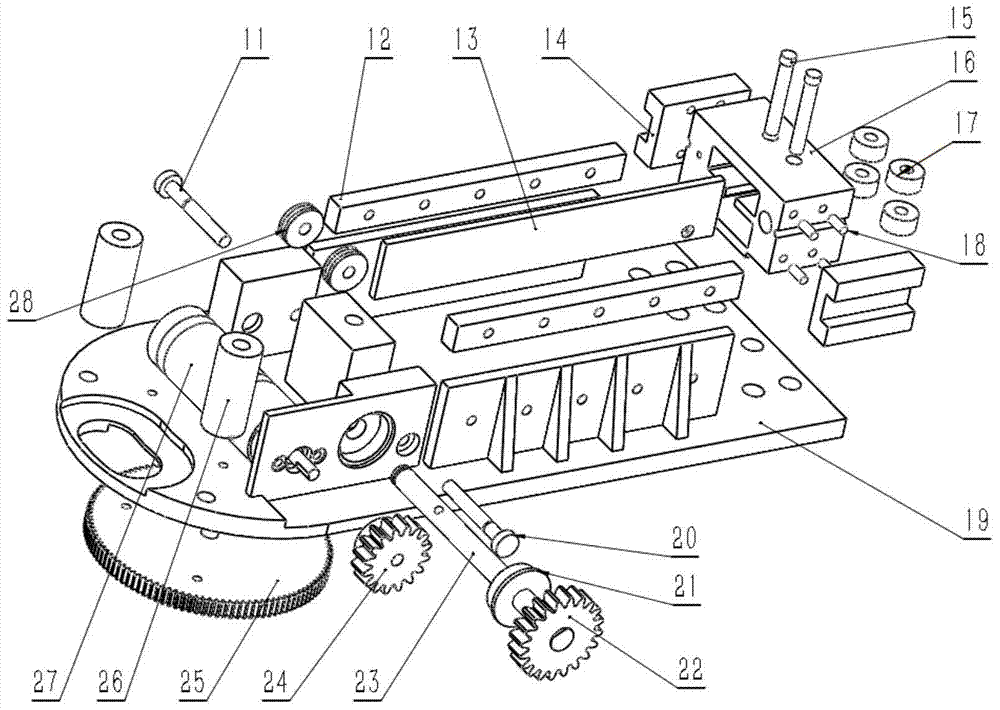

[0028] The invention provides a stable connection device with variable stiffness, which has the functions of stable connection and variable stiffness. Such as figure 1 , figure 2 with image 3 As shown, the entire stable connection device includes a mounting ring 1, an upper top plate 2, a top plate connecting plate 3, a bearing mounting frame 4, an upper plate rotating bearing 5, an upper plate rotating bearing retaining ring 6, an encoder 7, an encoder mounting frame 8, Reverse pulley shaft 9, reverse pulley 10, pulley shaft a11, slide rail 12, leaf spring 13, slide table 14, leaf spring bearing rod 15, slide block 16, leaf spring bearing 17, slide block slide table connection stick 18, Lower bottom plate 19, pulley shaft b20, winding shaft bearing 21, winding shaft gear 22, winding shaft 23, motor gear 24, bottom plate gear 25, connecting column 26, motor 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com