Method for determining working state of clutch of electric automobile

A technology of working status and electric vehicles, which is applied in the field of judging the working status of electric vehicle clutches, can solve the problems of increasing vehicle production costs and lack of space layout, and achieve the effect of optimizing control strategies and perfecting control functions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

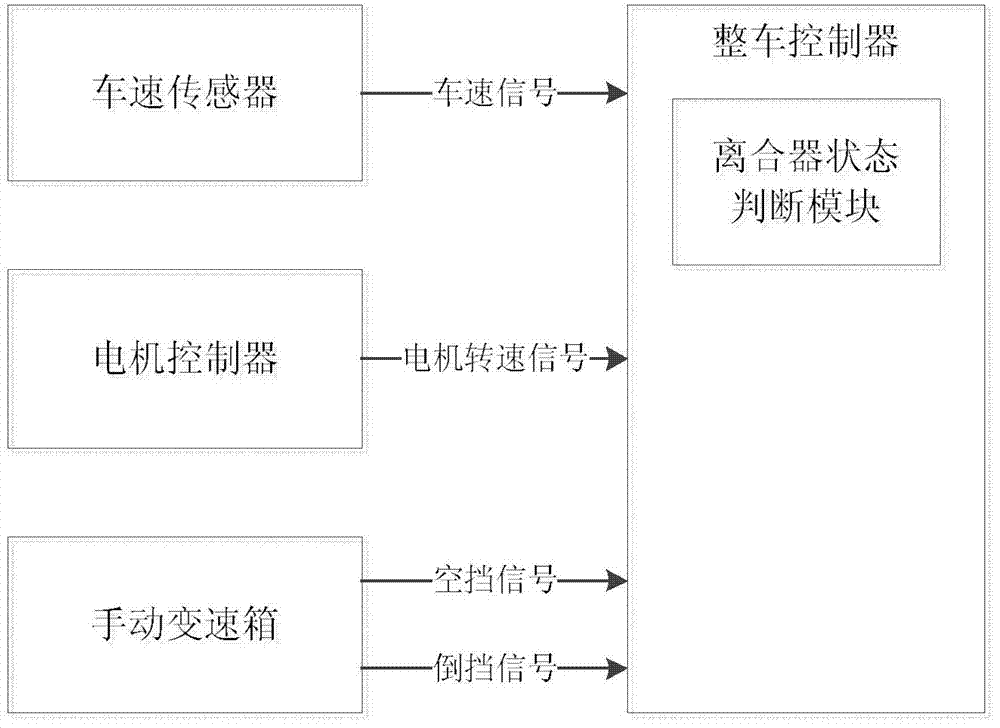

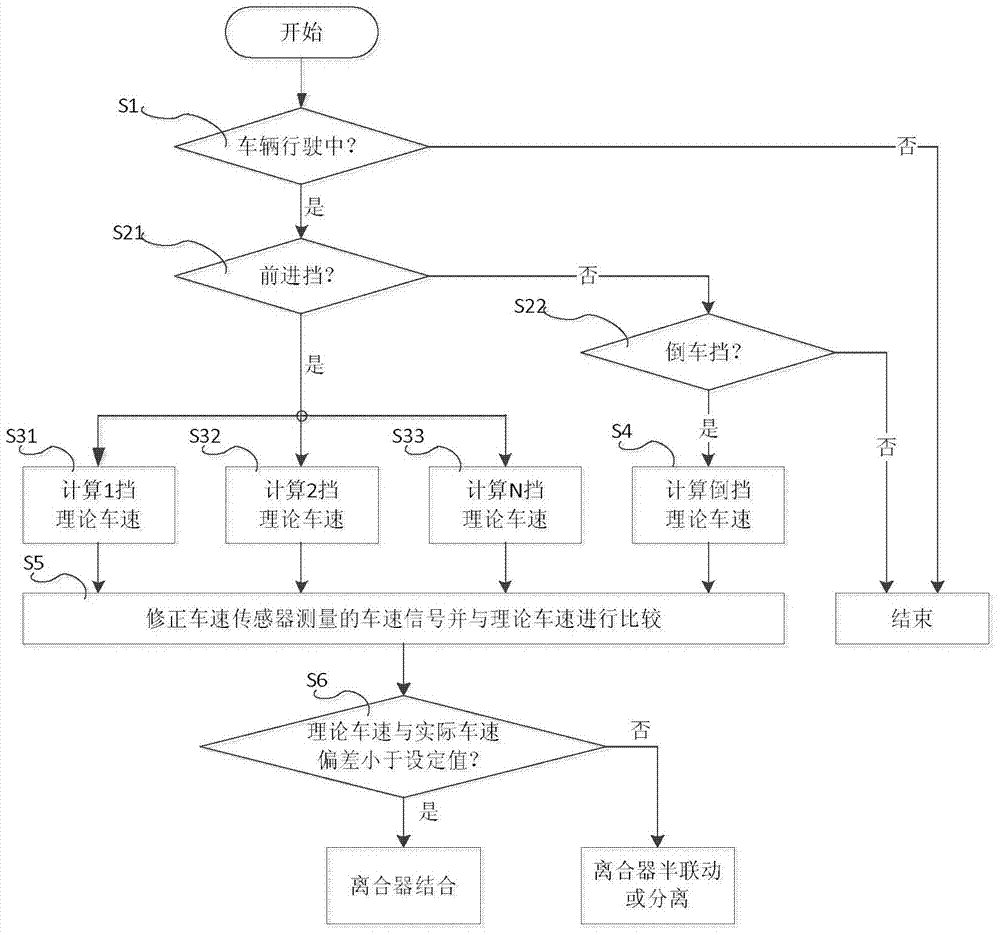

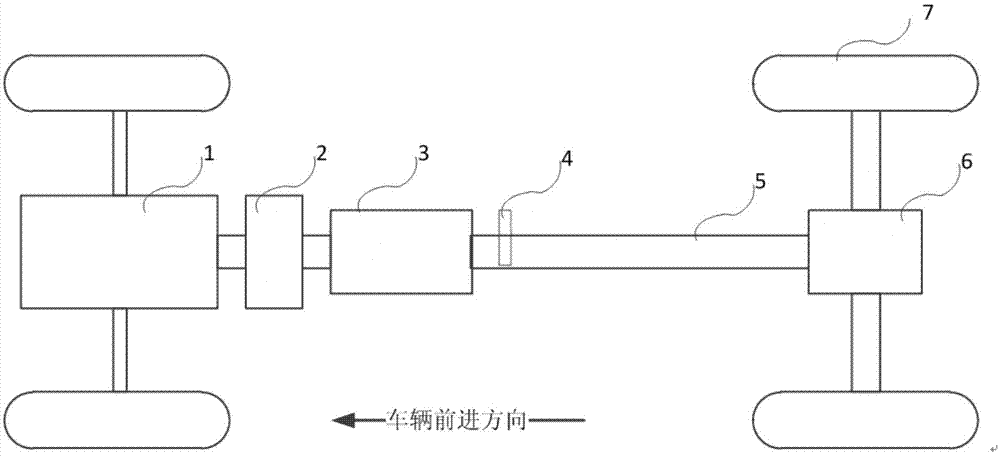

[0038] The schematic diagram of the drive train structure of a 7.5-ton pure electric garbage transfer vehicle is as follows: image 3As shown, the driving motor 1 is connected to the manual gearbox 3 through the clutch 2, and the output torque of the motor is transmitted to the rear wheels 7 via the transmission shaft 5 and the drive axle 6 to drive the vehicle. The clutch is controlled by the driver operating the clutch pedal. The signals needed to determine the working state of the clutch are: 1. Vehicle speed signal; 2. Actual speed signal of the driving motor; 3. Neutral gear signal; 4. Reverse gear signal. In addition, the parameters that need to be clarified include the reduction ratio of each gear of the gearbox, the main reduction ratio of the reducer, and the diameter of the tire. In this example, the reduction ratios of the five forward gears are 5, 2.5, 1.5, 1, 0.8, the reverse gear ratio is 4.4, the main reduction ratio is 5.286, and the tire diameter is 0.755m. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com