A locomotive traction braking method

A technology for locomotives and brake wedges, which is applied in the fields of locomotive traction and rail machinery transportation in mine level roads. It can solve problems such as sports car accidents, large cross-sections, and locking of braking devices, so as to prevent sports car accidents and reduce difficulty.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The structure of the present invention will be further described below in conjunction with the accompanying drawings.

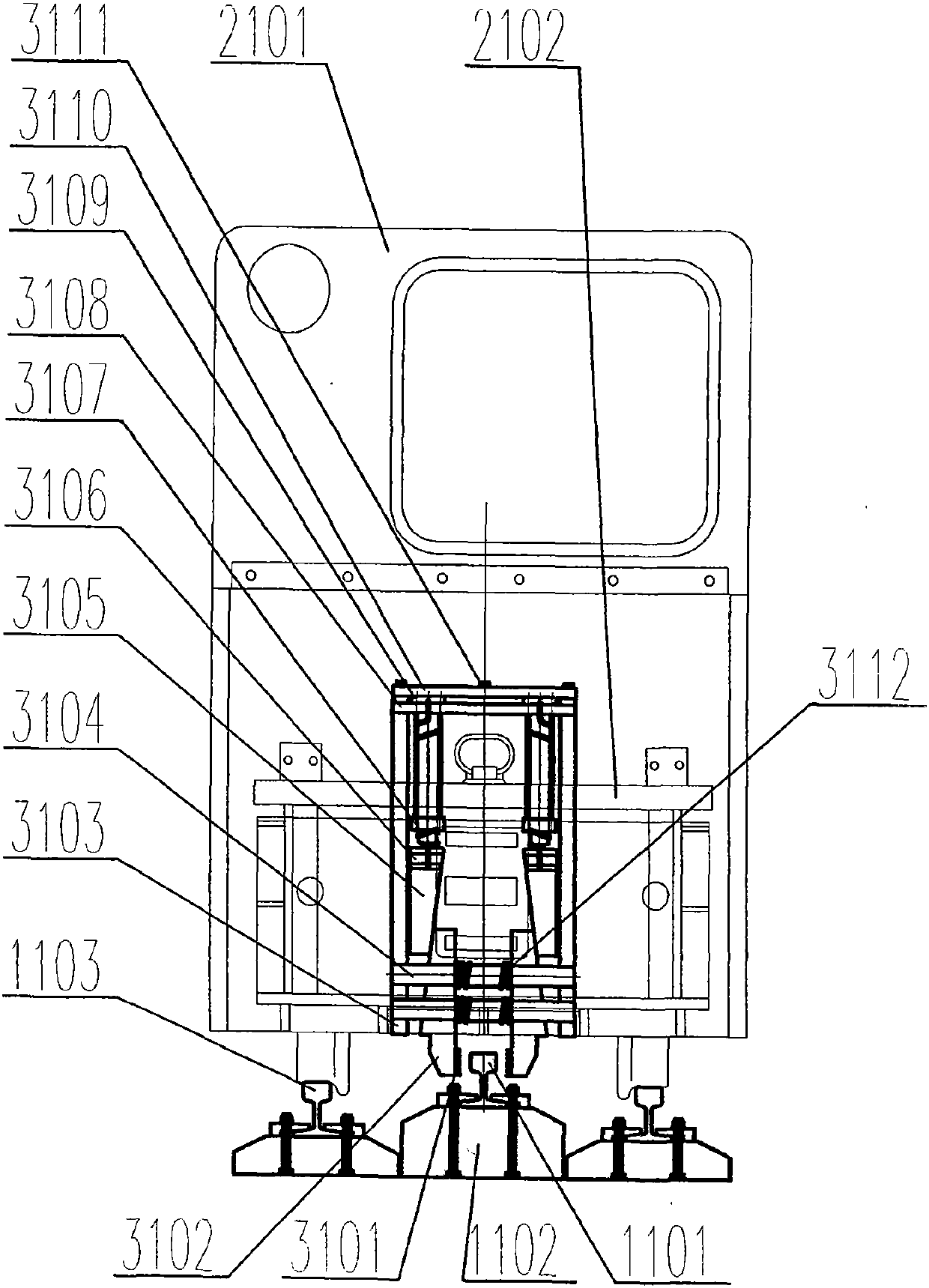

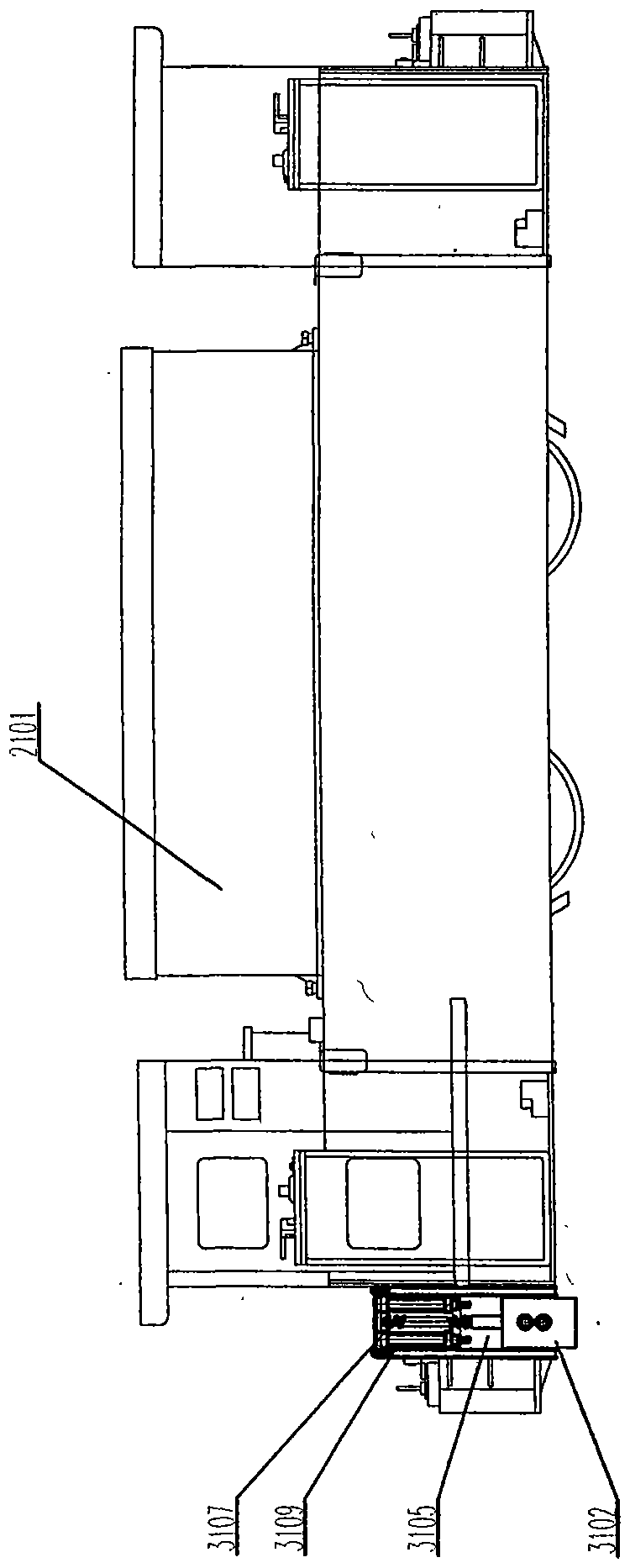

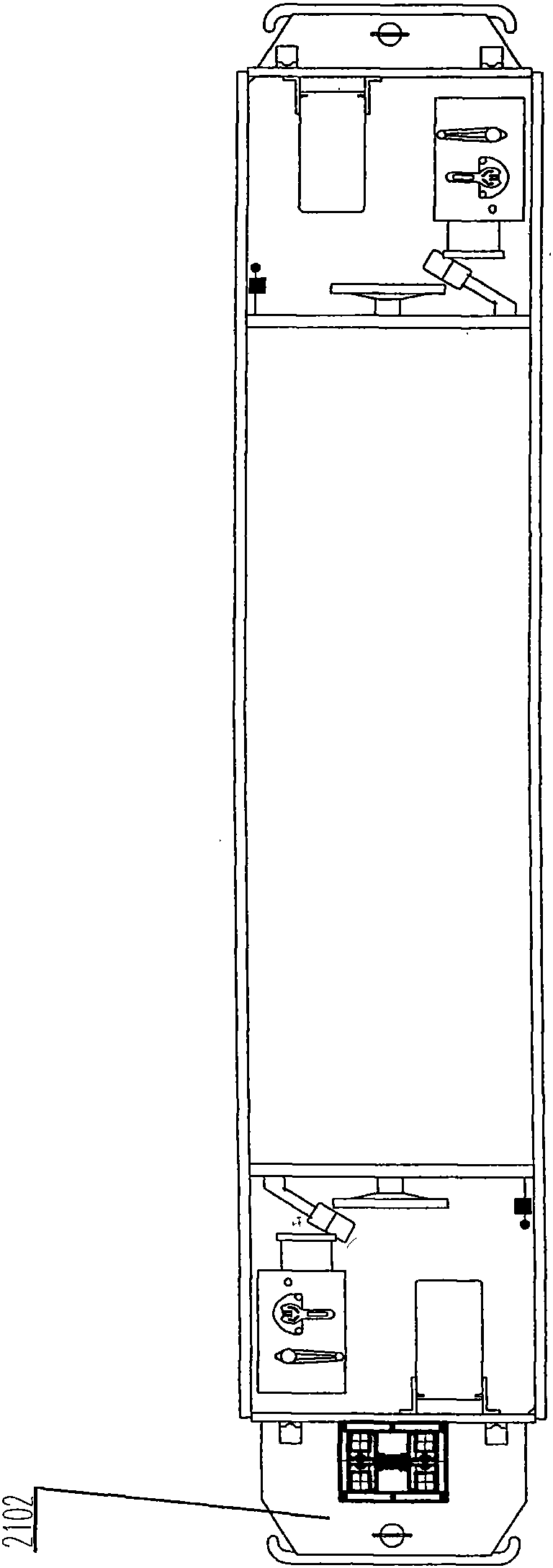

[0019] figure 1 , figure 2 , image 3 Middle: 1101. Brake track, 1102. Brake sleeper and pressing parts, 1103. Transportation road track, 2101. Locomotive body, 2102. Locomotive coupler meeting, 3101. Brake block, 3102. Brake wedge, 3103 .Brake box, 3104. Brake guide column, 3105. Booster wedge, 3106. Connecting pin, 3107. Return spring, 3108. Return spring fixing pin, 3109. Brake cylinder, 3110. Box cover , 3111. Bolt, 3112. Return spring.

[0020] Such as figure 1 , figure 2 , image 3 Shown, the technical scheme that the present invention takes:

[0021] The first step is to add a braking track 1101 on the track center line of the transportation road. The braking track 1101 is only laid on the straight line section of the transportation road track 1103, within the range of various turnouts and between various types of switches and the trans...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com