Pull-up diaper front and reverse packaging production line

A pull-up trousers and production line technology, which is applied in packaging and other directions, can solve the problems such as the inability to meet the packaging requirements of high-volume pull-up trousers products, only one or several products can be turned over, and the structure of the front and back lamination equipment is complicated, so as to save packaging. materials, improve packaging quality, and improve efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

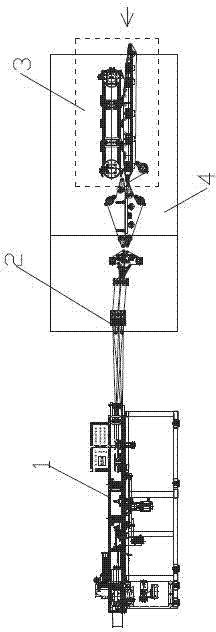

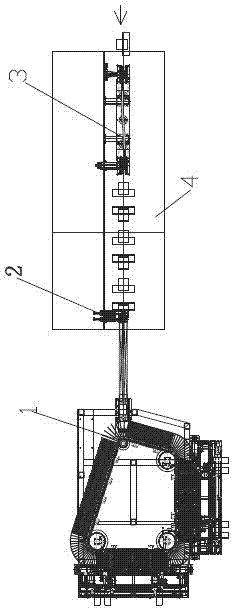

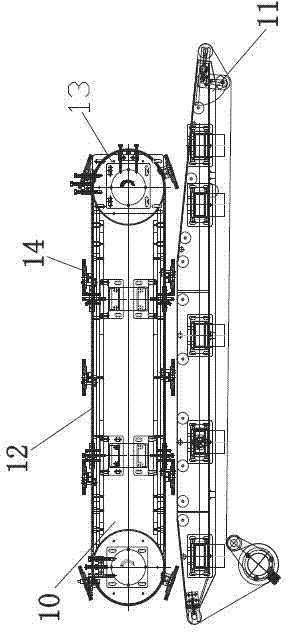

[0014] Embodiment 1: with reference to attached Figure 1-4 . A front and back packaging production line for pull-up trousers, which includes a stacker 1, a bagging machine (not shown in the figure) located at the outlet of the stacker 1, a stand-up device 2 located at the inlet of the stacker 1, And the rotating device 3 that is located at the inlet end of the stand-up device 2; the stacker 1, the packing bag machine and the stand-up device 2 are all prior art, and are not described in detail; the rotating device 3 includes a The upper annular conveying mechanism 10 and the lower annular conveying mechanism 11; the product channel is formed between the upper annular conveying mechanism 10 and the lower annular conveying mechanism 11; the lower annular conveying mechanism 11 is composed of a plurality of rollers The supporting endless conveyor belt is formed; the inlet end and the outlet end conveyor belt of the lower annular conveying mechanism 11 are all set to be inclined,...

Embodiment 2

[0017] Embodiment 2: On the basis of Embodiment 1, the servo motor 2 controls the small turntable 14 to rotate intermittently and continuously by 90°, that is, each small turntable 14 drives the product to rotate by 90° every time it travels on the upper circular conveying mechanism 10 , and then when driving another product, continue to rotate 90° in the original direction of rotation.

Embodiment 3

[0018] Embodiment 3: On the basis of Embodiment 1, the servo motor 5 controls the small turntable 14 to reset after rotating 90°, that is, after each small turntable 14 drives the product to rotate 90°, when the small turntable 14 is separated from the product, The servo motor 5 controls the small turntable 14 to slowly return to the original angular position.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com