A sliding trolley and its method for transporting overweight components

A trolley and component technology, applied in the field of handling, can solve problems such as large jacking force, complex air cushion process structure, harsh use environment and working conditions, etc., to reduce the pushing power and thrust, facilitate large-scale promotion, and reduce production costs cheap effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

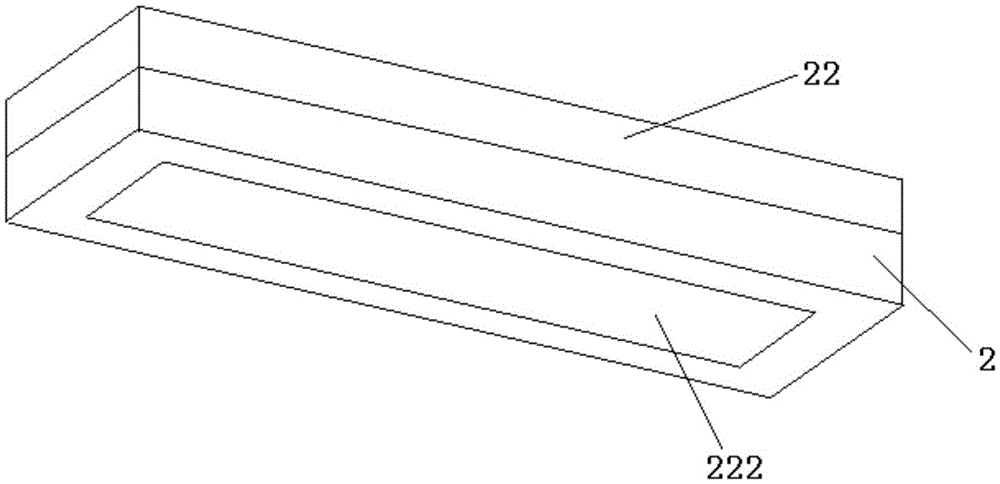

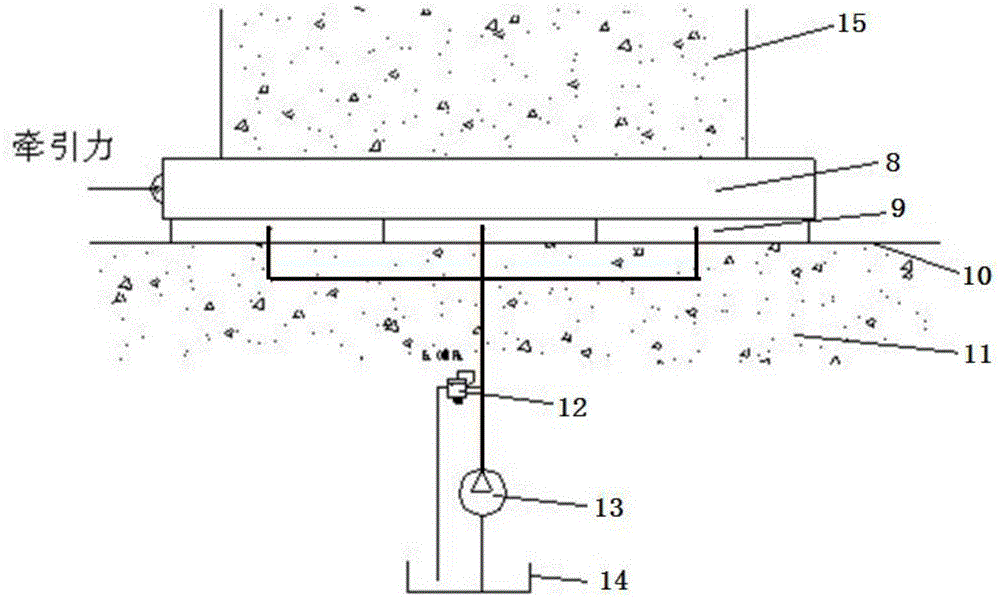

[0038] Such as figure 1 As shown, a kind of sliding trolley provided in this embodiment includes:

[0039] A slide plate and a high-pressure water chamber 222, the slide plate is a frame member, and the high-pressure water chamber 222 is located in the frame of the slide plate;

[0040] The slide plate includes: a slide material 2 and a support plate 22, and the support plate 22 is placed on the upper surface of the slide material 2; both the slide material 2 and the support plate 22 are frame-shaped components.

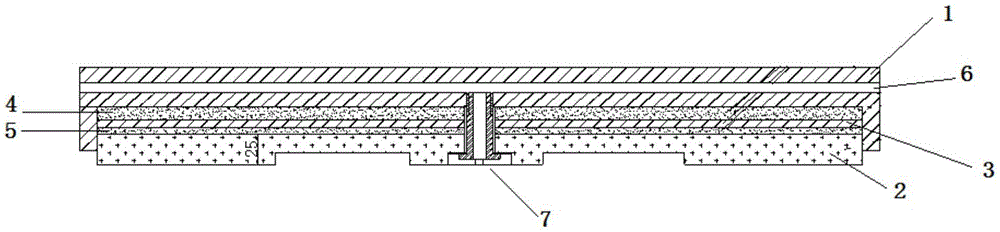

[0041] As preferred, such as figure 2 As shown, the sliding material 2 is a polytetrafluoroethylene plate, and the polytetrafluoroethylene plate is provided with a water inlet. Preferably, the support plate 22 includes: a first steel plate 1, a second steel plate 3, a first rubber plate 4, and a second rubber plate 5, the first steel plate 1 is stacked on the first rubber plate 4, and the first rubber plate The plate 4 is stacked on the second steel plate 3 , the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com