A kind of environment-friendly cavity mold box with large amount of industrial solid waste and preparation method thereof

An environmentally friendly, industrial solid waste technology, used in the field of building materials, can solve the problems of poor compressive strength, difficult construction, and high production costs, and achieve no environmental safety risks, large consumption, and excellent mechanical performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] 1) Configure raw materials: the weight percentage of each component is 36% of phosphogypsum, 10% of fly ash, 11% of desulfurized ash, 7% of quicklime, 2% of lightweight aggregate, and 34% of water.

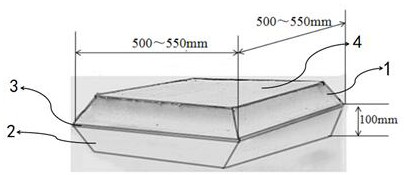

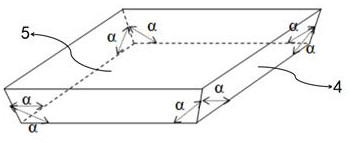

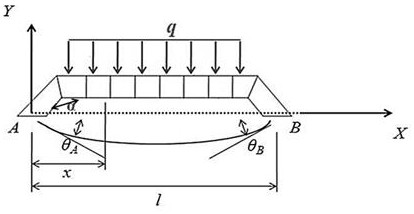

[0026] 2) Stir the raw materials evenly, then add water to mix and stir evenly, and then cast them in the mold for 10-14 hours under natural conditions, and then remove the mold. The obtained cavity mold box is as follows: figure 1 and figure 2 As shown, it includes an upper module 1 and a lower module 2, the upper module and the lower module can be docked to form a box structure with a cavity inside, and each of the upper module 1 and the lower module 2 is a rectangular frustum-shaped structure, and The large-area end face of the rectangular truncated cone structure is the butt end face 3, and the middle part of the butt end face is concavely formed with a first cavity 5; the respective rectangular truncated cone structures of the upper module and the lower module converg...

Embodiment 2

[0044] 1) Configure raw materials: the weight percentage of each component is 39% of phosphogypsum, 9% of fly ash, 8% of desulfurized ash, 8% of quicklime, 3% of lightweight aggregate, and 33% of water.

[0045] 2) Stir the raw materials evenly, then add water to mix and stir evenly, and then cast them in the mold for 10-14 hours under natural conditions, and then remove the mold. The obtained cavity mold box includes an upper module and a lower module; the upper module and the lower module The lower module can be docked to form a box structure with a cavity inside. The upper module and the lower module each have a rectangular frustum-shaped structure, and the large-area end surface of the rectangular frustum-shaped structure is a butt end surface, and the butt end surface The middle part is concavely formed with a first concave cavity; the angle α between any two adjacent edges between the three edges converging to a vertex on the respective rectangular frustum-shaped structur...

Embodiment 3

[0051] 1) Configure raw materials: the weight percentage of each component is 42% of phosphogypsum, 8% of fly ash, 7% of desulfurized ash, 9% of quicklime, 3% of lightweight aggregate, and 31% of water.

[0052] 2) Stir the raw materials evenly, then add water to mix and stir evenly, then cast in the mold for 10-14 hours under natural conditions, and then remove the mold. The obtained cavity mold box includes an upper module and a lower module, the upper module and the lower module The lower module can be docked to form a box structure with a cavity inside. The upper module and the lower module each have a rectangular frustum-shaped structure, and the large-area end surface of the rectangular frustum-shaped structure is a butt end surface, and the butt end surface The middle part is concavely formed with a first concave cavity; the angle α between any two adjacent edges between the three edges converging to a vertex on the respective rectangular frustum-shaped structures of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| cylinder compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com