Glass cutter

A cutting machine and glass technology, applied in glass cutting devices, glass manufacturing equipment, manufacturing tools, etc., can solve the problem of not being able to cut arcs or circles, and achieve the effect of simple structure and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

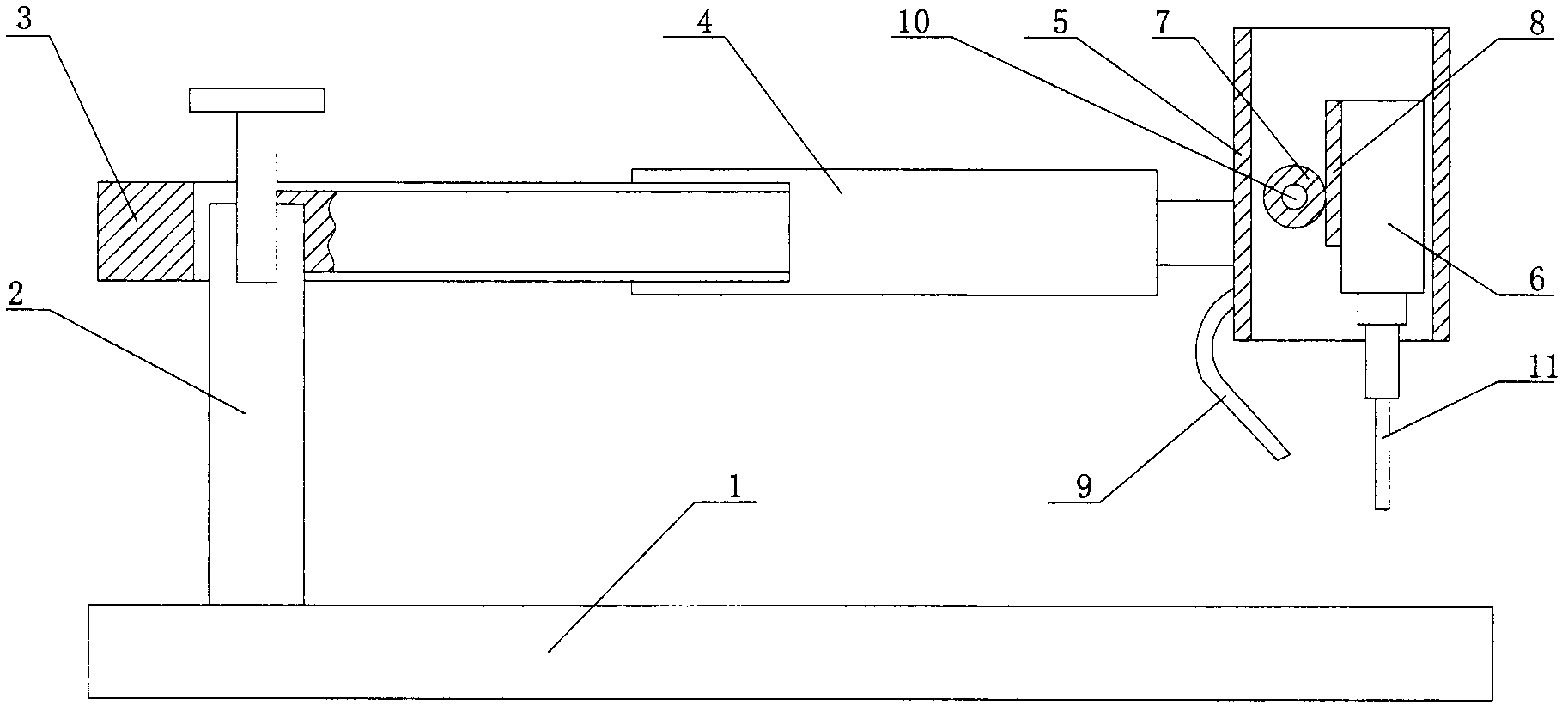

[0008] The present invention will be further described below in conjunction with the accompanying drawings.

[0009] Such as figure 1 As shown, the present invention includes a base 1 and a column 2 fixed on the base 1. The column 2 is provided with a first cantilever 3 which rotates around the column 2. The end of the first cantilever 3 is provided with a The second cantilever 4 of the radial expansion of the first cantilever 3, the end of the second cantilever 4 is fixed with a motor jacket 5, the motor jacket 5 is provided with a motor 6, one side of the motor 6 is provided with a rack 8, and the motor jacket 5 is also provided with a gear 7 meshing with the rack 8, and the outside of the jacket is also provided with a handle 9 for controlling the motor to move up and down. The end of the handle 9 passes through the motor jacket 5 through the fixed shaft 10, and is connected with the motor clamp The gear 7 in the cover 5 is connected. The bottom of the motor jacket is pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com