A kind of pre-dispersed comprehensive anti-scorch accelerator masterbatch and preparation method thereof

A technology of pre-dispersion and accelerator, applied in the field of pre-dispersion comprehensive anti-scorch accelerator masterbatch and its preparation, to achieve the effects of accurate feeding, overcoming high toxicity and shortening vulcanization time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

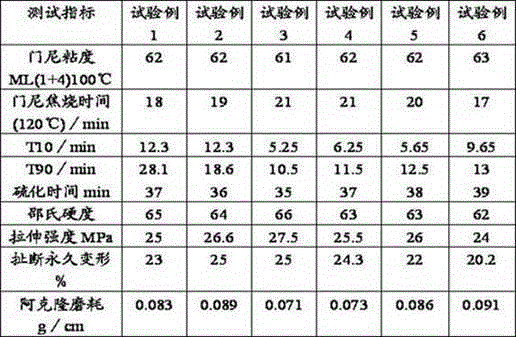

Examples

Embodiment 1

[0024] A pre-dispersed comprehensive anti-scorch accelerator masterbatch, composed of the following materials in parts by weight: 60 parts of accelerator NS, 7 parts of anti-scorch agent CTP, 5 parts of carrier rubber, 8 parts of naphthenic mineral oil, 3 parts of paraffin, 2 servings of PETS.

[0025] The carrier rubber is 5 parts of natural rubber NR.

[0026] The method for preparing the pre-dispersed comprehensive anti-scorch accelerator masterbatch, the specific steps are as follows:

[0027] (1) According to the formula ratio, plasticize the carrier rubber and PETS evenly in an open mixer with a speed of 24r / min, and then put them into an internal mixer equipped with CTP, NS, naphthenic mineral oil, paraffin and PETS at 110r / min / min speed, kneading at a temperature of 45°C, after mixing evenly, discharge;

[0028] (2) Put the material obtained in step (1) into the transport hopper, transport it to a conical twin-screw kneader with a rotation speed of 110r / min, and dir...

Embodiment 2

[0032] A pre-dispersed comprehensive anti-scorch accelerator masterbatch, composed of the following materials in parts by weight: 65 parts of accelerator NS, 12 parts of anti-scorch agent CTP, 11.5 parts of carrier rubber, 9 parts of naphthenic mineral oil, 1 part of paraffin, PETS1.5 copies.

[0033] The carrier rubber is 6 parts of natural rubber NR and 5.5 parts of butadiene rubber.

[0034] The method for preparing the pre-dispersed comprehensive anti-scorch accelerator masterbatch, the specific steps are as follows:

[0035] (1) According to the formula ratio, plasticize the carrier rubber and PETS evenly in an open mixer with a speed of 24r / min, and then put them into an internal mixer equipped with CTP, NS, naphthenic mineral oil, paraffin and PETS at 190r / min / min speed, kneading temperature of 60°C, after mixing evenly, discharge;

[0036] (2) Put the material obtained in step (1) into the transport hopper, transport it to a conical twin-screw kneader with a rotatio...

Embodiment 3

[0040] A pre-dispersed comprehensive anti-scorch accelerator masterbatch, composed of the following materials in parts by weight: 71 parts of accelerator NS, 9 parts of anti-scorch agent CTP, 10 parts of carrier rubber, 7 parts of naphthenic mineral oil, 2 parts of paraffin, 1 serving of PETS.

[0041] The carrier rubber is 8 parts of EPDM and 2 parts of styrene-butadiene rubber.

[0042] The method for preparing the pre-dispersed comprehensive anti-scorch accelerator masterbatch, the specific steps are as follows:

[0043] (1) According to the formula ratio, plasticize the carrier rubber and PETS evenly in an open mixer with a speed of 24r / min, and then put them into an internal mixer equipped with CTP, NS, naphthenic mineral oil, paraffin and PETS at 160r / min Kneading at a speed of 1 / min and a temperature of 70°C, after mixing evenly, discharge;

[0044] (2) Put the material obtained in step (1) into the transport hopper, transport it to a conical twin-screw kneader with a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com