A kind of chrome-plated automatic spray paint and preparation method thereof

An automatic painting and paint technology, applied in the direction of coating, etc., can solve the problems of anesthesia of the central nervous system, no mirror decoration effect, darkening and blackening of the paint film, etc., and achieve excellent comprehensive performance, resistance to ultraviolet radiation, and rapid drying Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

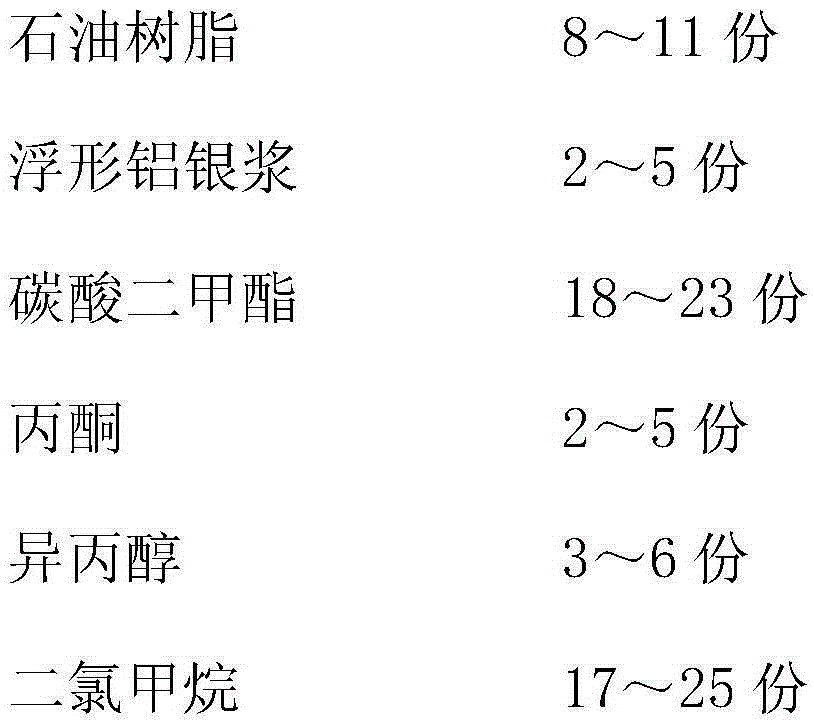

[0033] Embodiment 1: (taking the deployment of 650 kg of A-component paint as an example)

[0034] Petroleum resin 105kg, floating aluminum silver paste 36kg, DMC 203kg, acetone 32kg, isopropanol 26kg, dichloromethane 195kg, D-4053kg;

[0035] LPG350kg;

[0036] The preparation method is: mix 105kg of petroleum resin with 70kg of DMC, stir at 1500r / min for 20min until completely dissolved and transparent to petroleum resin liquid; add 36kg of floating aluminum-silver paste to the dissolved petroleum resin liquid, 133kg of DMC remaining, acetone 32kg, isopropanol 26kg, dichloromethane 195kg, D-4053kg, stir evenly with 1500r / min, be 11-13S to meet the requirement with coating 4-cup detection viscosity, obtain semi-finished product; The semi-finished product that will obtain is filtered through 180 mesh bags Machine filter to remove all kinds of impurities and large particles. After packing into tanks, fill the cap with LPG according to the weight ratio of paint to LPG: 1:0.54. ...

Embodiment 2

[0037] Embodiment 2: (taking the deployment of 650 kg of A-component paint as an example)

[0038] Petroleum resin 80kg, floating aluminum silver paste 50kg, DMC 180kg, acetone 20kg, isopropanol 30kg, dichloromethane 250kg, D-4040kg;

[0039] LPG338kg;

[0040] The preparation method is as follows: mix petroleum resin with 60kg of DMC, stir at 1500r / min for 20min until completely dissolved and transparent to petroleum resin liquid; add floating aluminum silver paste to the dissolved petroleum resin liquid, the remaining amount of DMC, acetone, isopropyl Alcohol, dichloromethane, D-40, stir evenly at 1500r / min, use a 4-cup to detect that the viscosity is 11-13S and meet the requirements, and obtain a semi-finished product; filter the obtained semi-finished product through a 175-mesh bag filter to remove various impurities And large particles, after packing into cans, fill the cap with LPG according to the weight ratio of paint to LPG 1:0.52.

Embodiment 3

[0041] Embodiment 3: (taking the deployment of 650 kg of A-component paint as an example)

[0042] Petroleum resin 90kg, floating aluminum silver paste 20kg, DMC 230kg, acetone 30kg, isopropanol 50kg, dichloromethane 170kg, D-4060kg;

[0043] LPG364kg;

[0044] The preparation method is as follows: mix petroleum resin with 70kg of DMC, stir at 1500r / min for 20min until completely dissolved and transparent to petroleum resin liquid; add floating aluminum silver paste to the dissolved petroleum resin liquid, the remaining amount of DMC, acetone, isopropyl Alcohol, dichloromethane, D-40, stir evenly at 1500r / min, use a 4-cup to detect that the viscosity is 11-13S and meet the requirements, and obtain a semi-finished product; filter the obtained semi-finished product through a 185-mesh bag filter to remove various impurities And large particles, after packing into cans, fill the cap with LPG according to the weight ratio of paint to LPG 1:0.56.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com