Temporary advanced support device

A kind of advanced support and temporary technology, applied in pillars/supports, mining equipment, earthwork drilling and other directions, can solve the problems of high labor intensity, collapse and collapse of the blasting face, and many workers, so as to achieve a small occupation space, Easy to install and easy to move

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

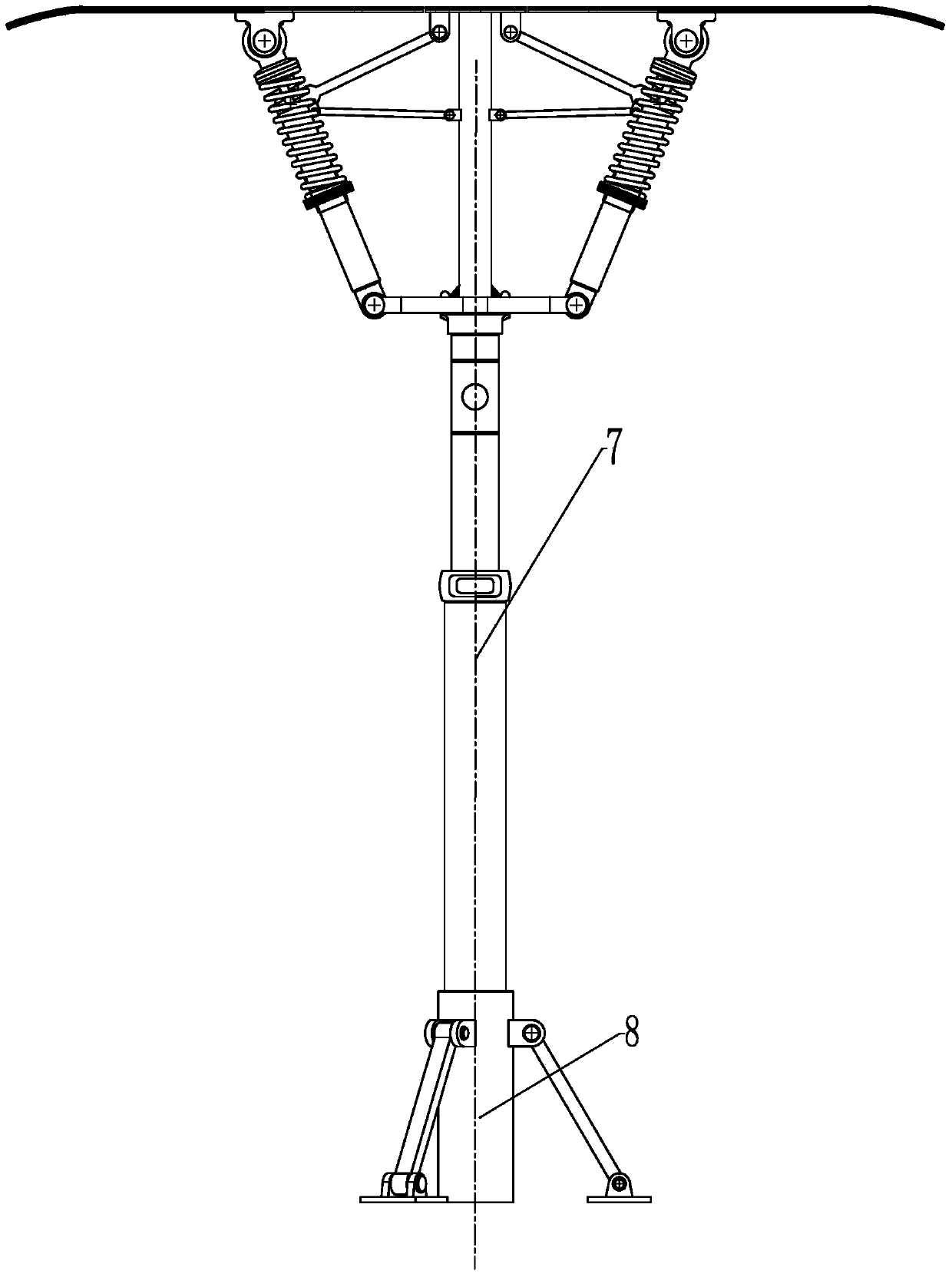

[0028] like figure 1 , figure 2 The embodiment shown is a temporary advance support device, which includes a single hydraulic prop 7, and the top cover of the single hydraulic prop 7 is equipped with an expanded top beam, which is mainly composed of a frame 1, an upper link 2. A linkage mechanism composed of roof beam frame 3, support rod 4, support frame 5 and lower link 6. The upper link 2, roof beam frame 3, support rod 4 and lower link 6 are formed along the support frame 5. The central axis is symmetrically arranged in pairs.

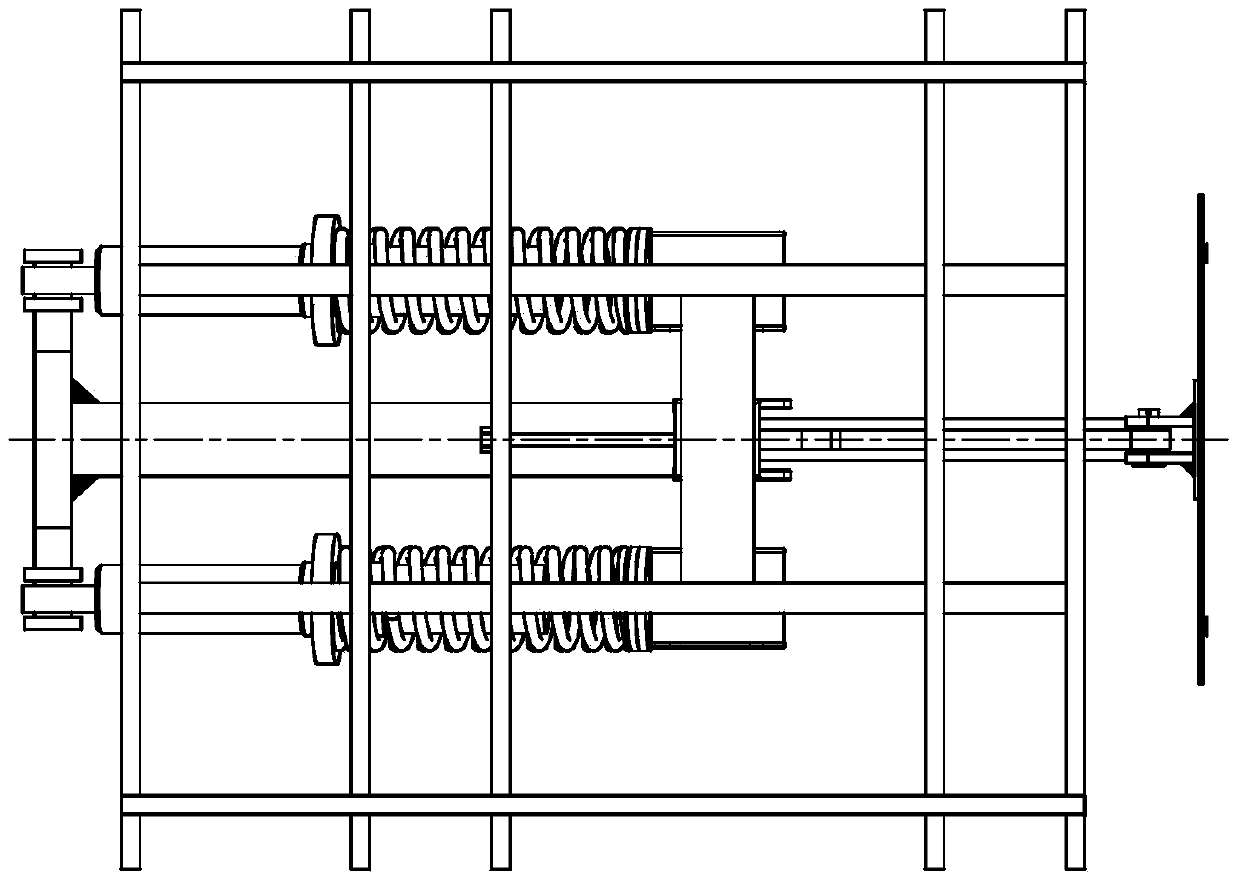

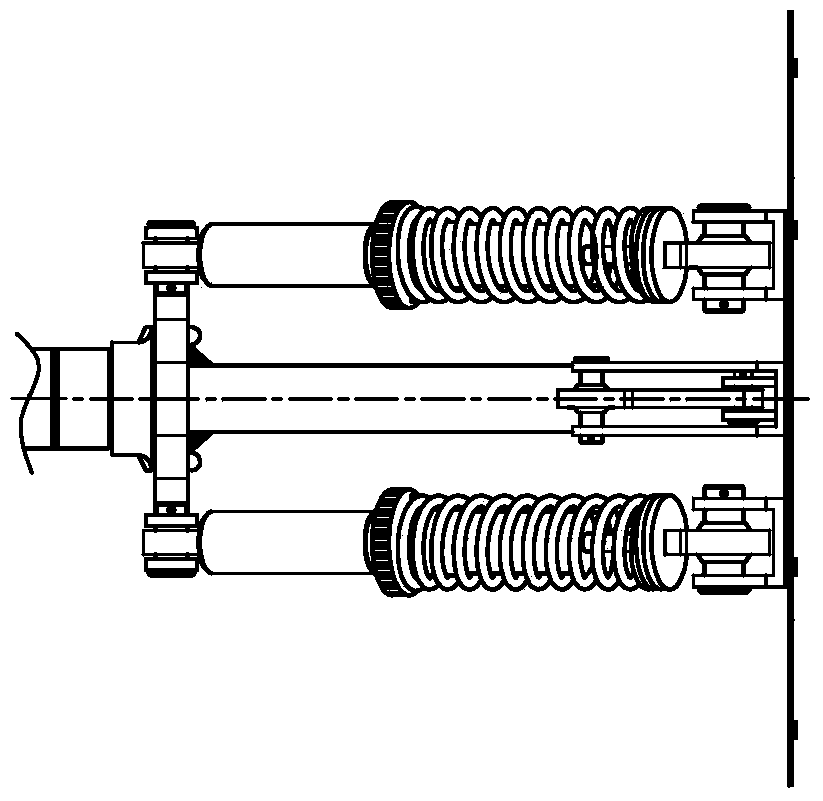

[0029] like figure 2 , image 3 , Figure 4 , Figure 5 As shown, a support rod 5-1 is fixed in the middle of the support frame 5, a connecting rod 3-1 is fixedly connected to the top beam frame 3, and a pair of The upper link 2 mentioned above, the lower end of the upper link 2 is at the hinge point b Hinge described connecting rod 3-1, the upper end of described support rod 4 is at hinge point c Hinged on the top beam frame 3, the lower...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com