Multistage speed changing device

A technology of speed change mechanism and tower gear, applied in the direction of transmission device, transmission device parts, gear transmission device, etc., can solve the problems of high technical requirements for manufacturing and maintenance, complex structure of speed change mechanism, inconvenient operation, etc., to reduce the complexity of assembly process and Technical, outstanding substantive features, easy to control effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

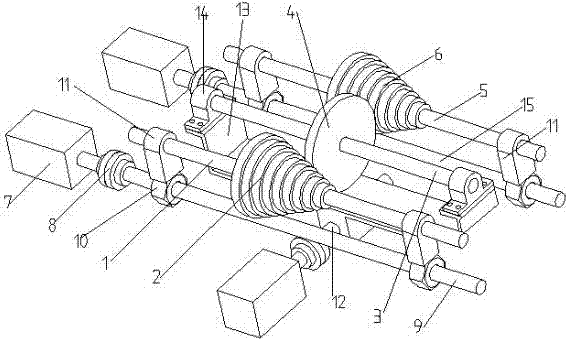

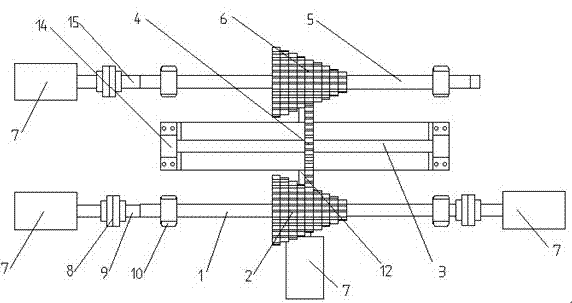

[0032] In order to clearly illustrate the technical characteristics of this solution, the following will describe this solution through specific implementation modes and in conjunction with the accompanying drawings.

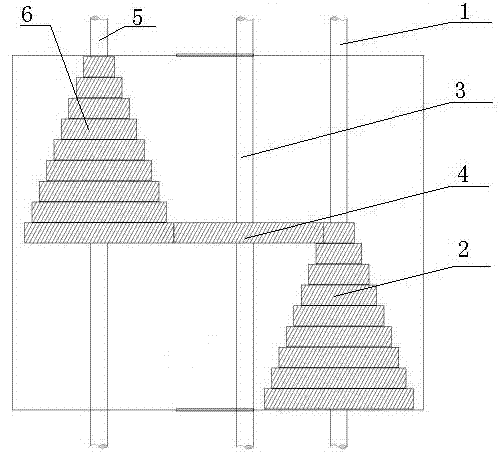

[0033] Such as figure 1 and figure 2 Shown: a multi-stage transmission mechanism, which includes a power input shaft 1, an intermediate transmission body and a power output shaft 5, the power input shaft 1 is provided with a driving tower gear 2, and the power output shaft 5 is provided with a The driving tower gear 2 is matched with the driven tower gear 6 , and one driving gear in the driving tower gear 2 meshes with a corresponding driven gear in the driven tower gear 6 through an intermediate transmission body for transmission.

[0034] The above-mentioned intermediate transmission body includes a radially movable transmission shaft 3 on which a transmission gear 4 is arranged, and the axes of the power input shaft 1 , transmission shaft 3 and power output...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com