Digital level sensor

A level sensor, digital technology, used in instruments, mapping and navigation, measuring devices, etc., can solve problems such as stability and reliability that cannot meet the requirements of use, inconvenient automatic measurement and automatic control, and inability to generate electrical signals. Conducive to long-distance transmission, reducing measurement time and ensuring reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The present invention will be further described below in conjunction with embodiment.

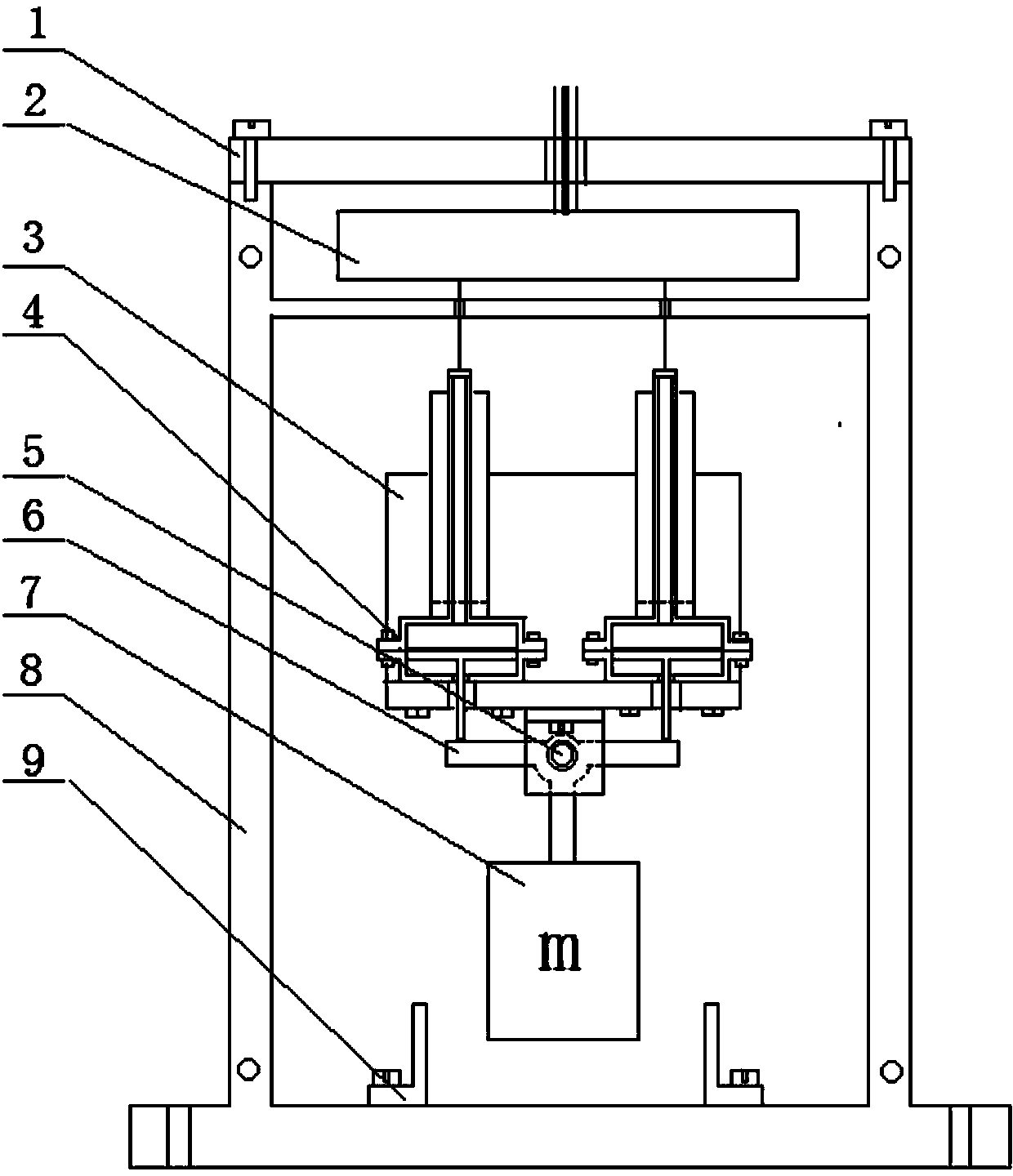

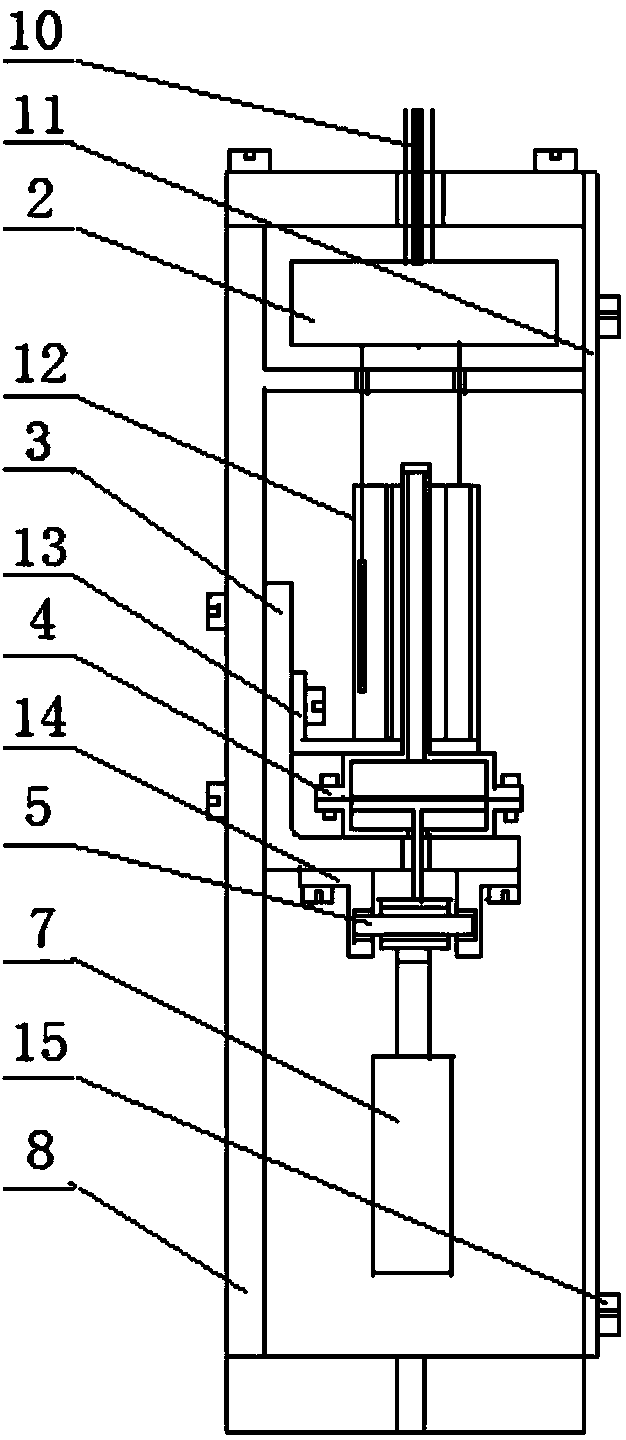

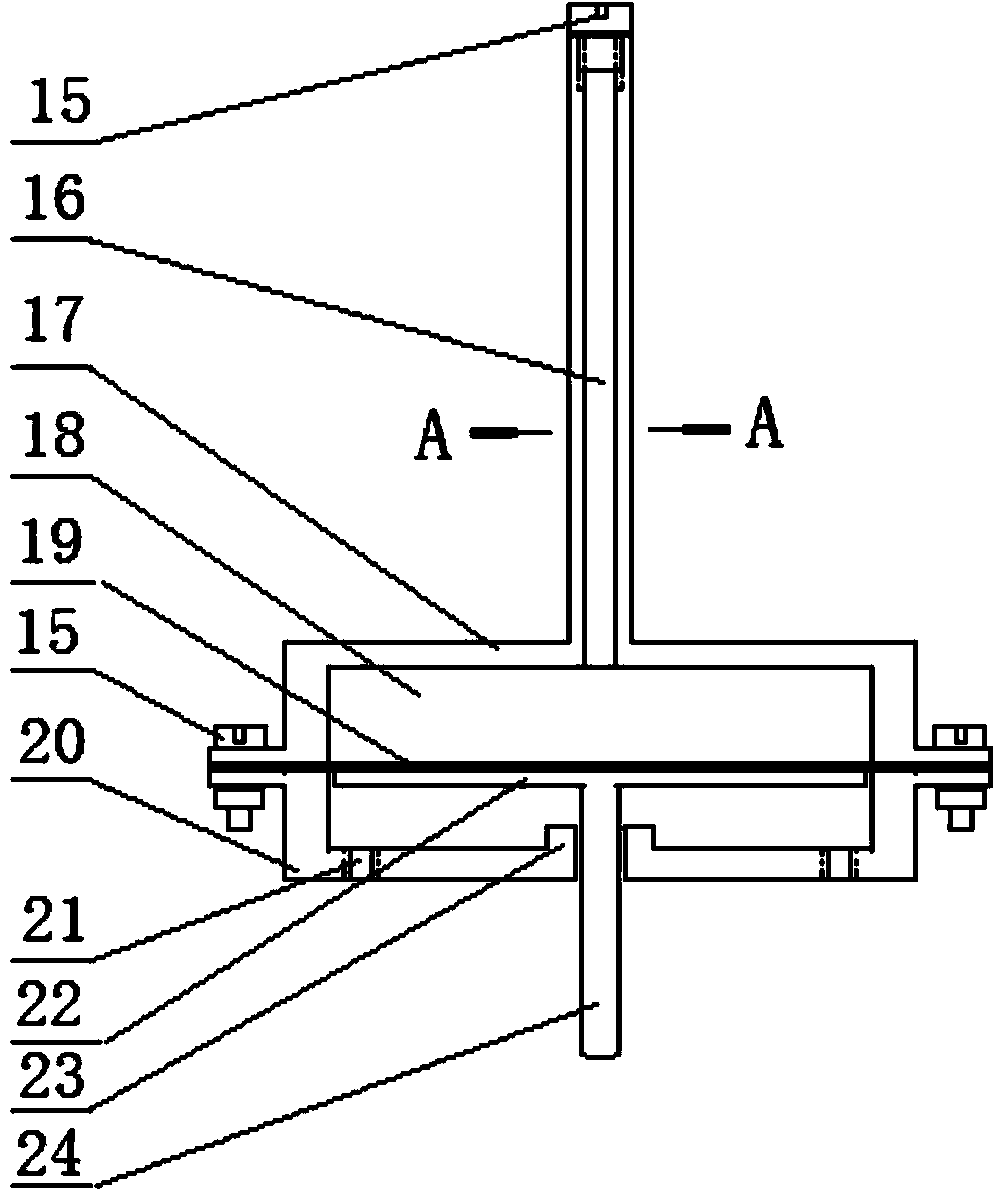

[0048] A digital level sensor, including a casing, is provided with a circuit system, a suspension pendulum part, a hydraulic micro-displacement amplification part 4 and a parallel light source in the casing, such as Figure 1 to Figure 9 As shown, among them,

[0049] The structure of described circuit system is: comprise microprocessor 31, CCD drive circuit 32, LED drive circuit 34, signal processing circuit 33 and linear array CCD26, wherein, microprocessor 31 is connected with the LED array of parallel light source by LED drive circuit 34 28 is connected; Microprocessor 31 is connected 26 with linear array CCD by CCD driving circuit 32; Microprocessor 31 is connected with signal processing circuit 33, and signal processing circuit 33 is connected with linear array CCD26;

[0050] The structure of the suspended pendulum part is: comprising a pendulum 7, a T-shaped push rod 6, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com