Silica-based unit board of LED display screen

A technology of LED display screen and unit board, which is applied in the direction of instruments, identification devices, etc., to achieve the effect of small pixel pitch, convenient production, and no need for packaging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described below in conjunction with specific examples.

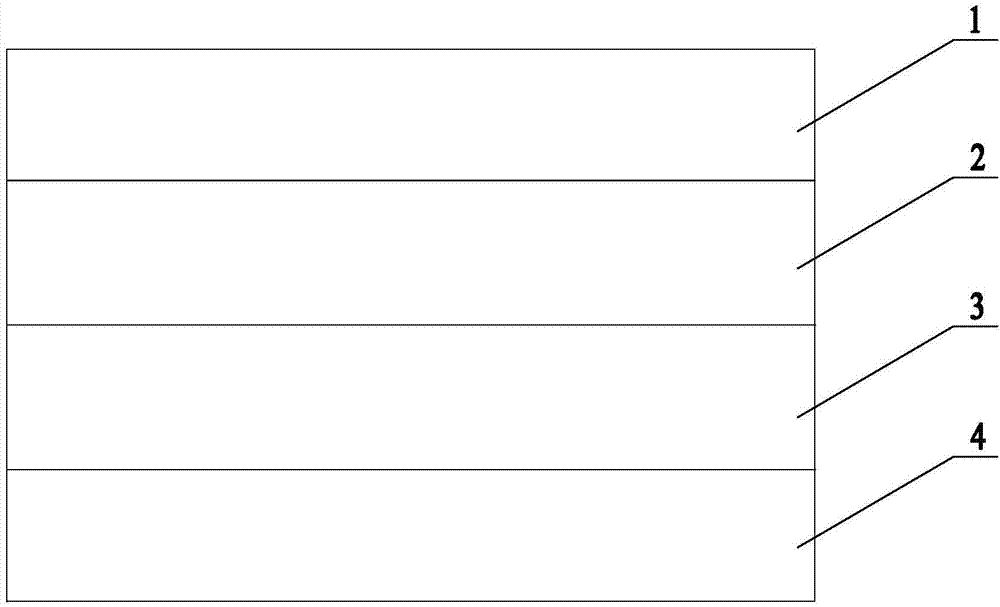

[0011] The silicon-based LED display unit board includes an LED light-emitting unit 1, a silicon substrate unit 2, a circuit board unit 3 and an electronic component unit 4, and the upper surface of the silicon substrate unit 2 is connected with the LED light-emitting unit 1 and the silicon substrate unit 2. The lower surface of the circuit board unit 3 is connected to the upper surface of the circuit board unit 3, and the electronic component unit 4 is connected to the lower surface of the circuit board unit 3; the LED light emitting unit 1 is composed of LED pixels, and each LED pixel is composed of 1~3 LEDs Composed of light-emitting individuals, each LED light-emitting individual is an LED flip-chip, and the distance between LED pixels is 0.1~0.5mm.

[0012] The silicon substrate unit 2 is made of silicon.

[0013] The circuit board unit 3 is made of glass fiber board or ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com