Evaporator assembly and evaporator assembly for electric car battery pack

An evaporator assembly and assembly technology, which is applied in the field of cooling equipment, can solve the problems of long cooling capacity transportation path, poor temperature consistency, and poor cooling effect of single-core evaporators, so as to shorten the refrigerant circulation path and circulation cycle, Solve the problem of uneven temperature and ensure the effect of temperature consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

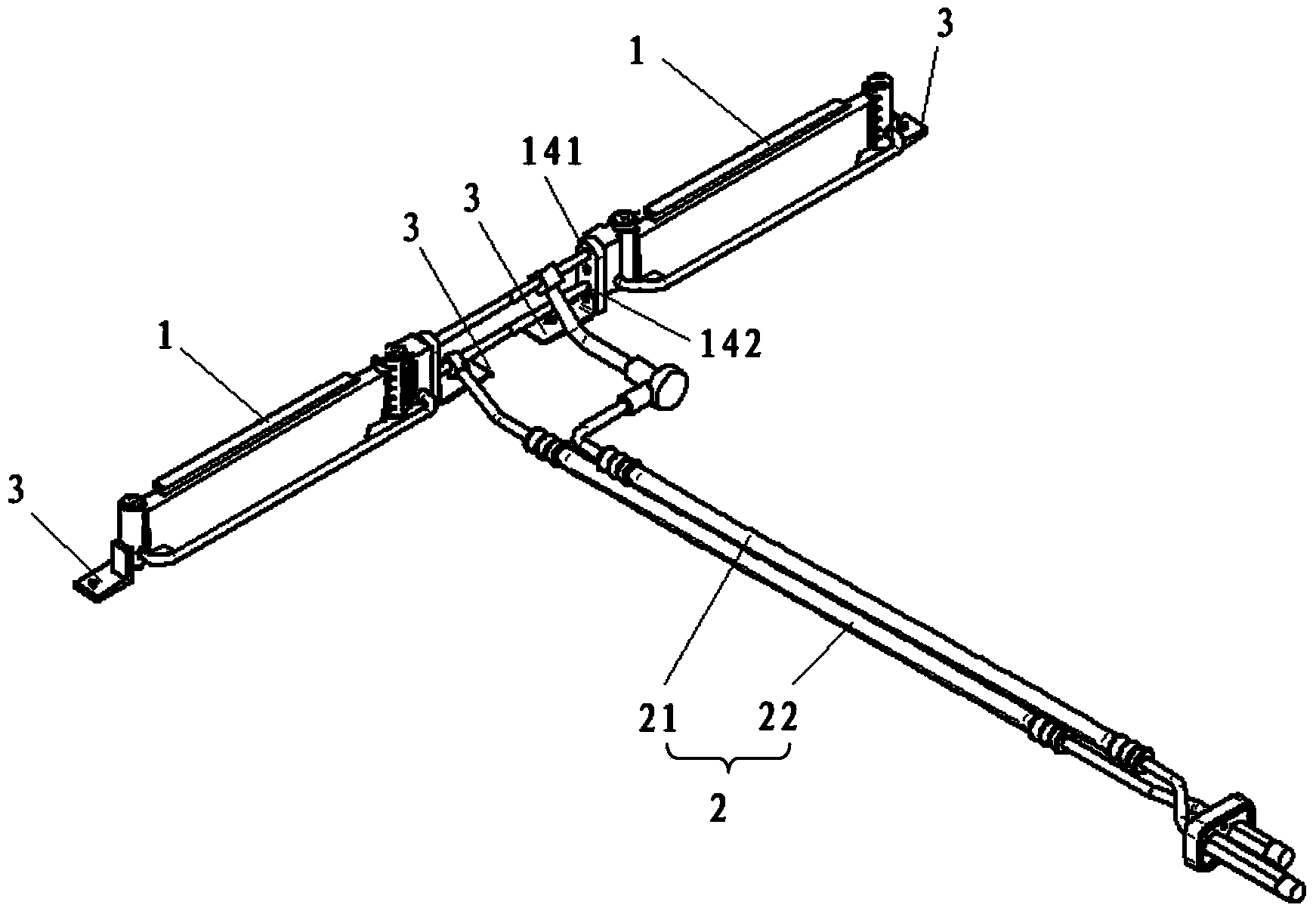

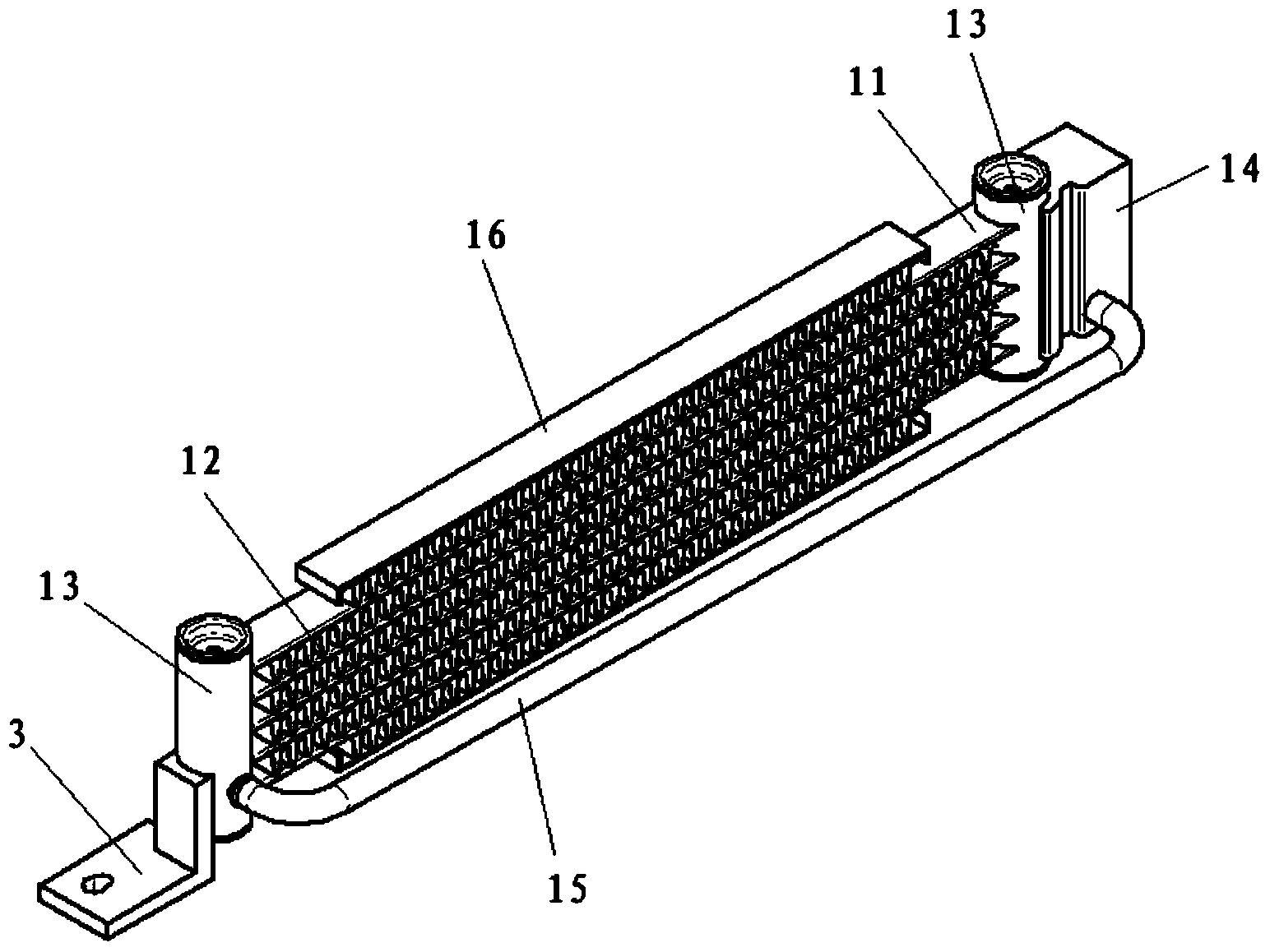

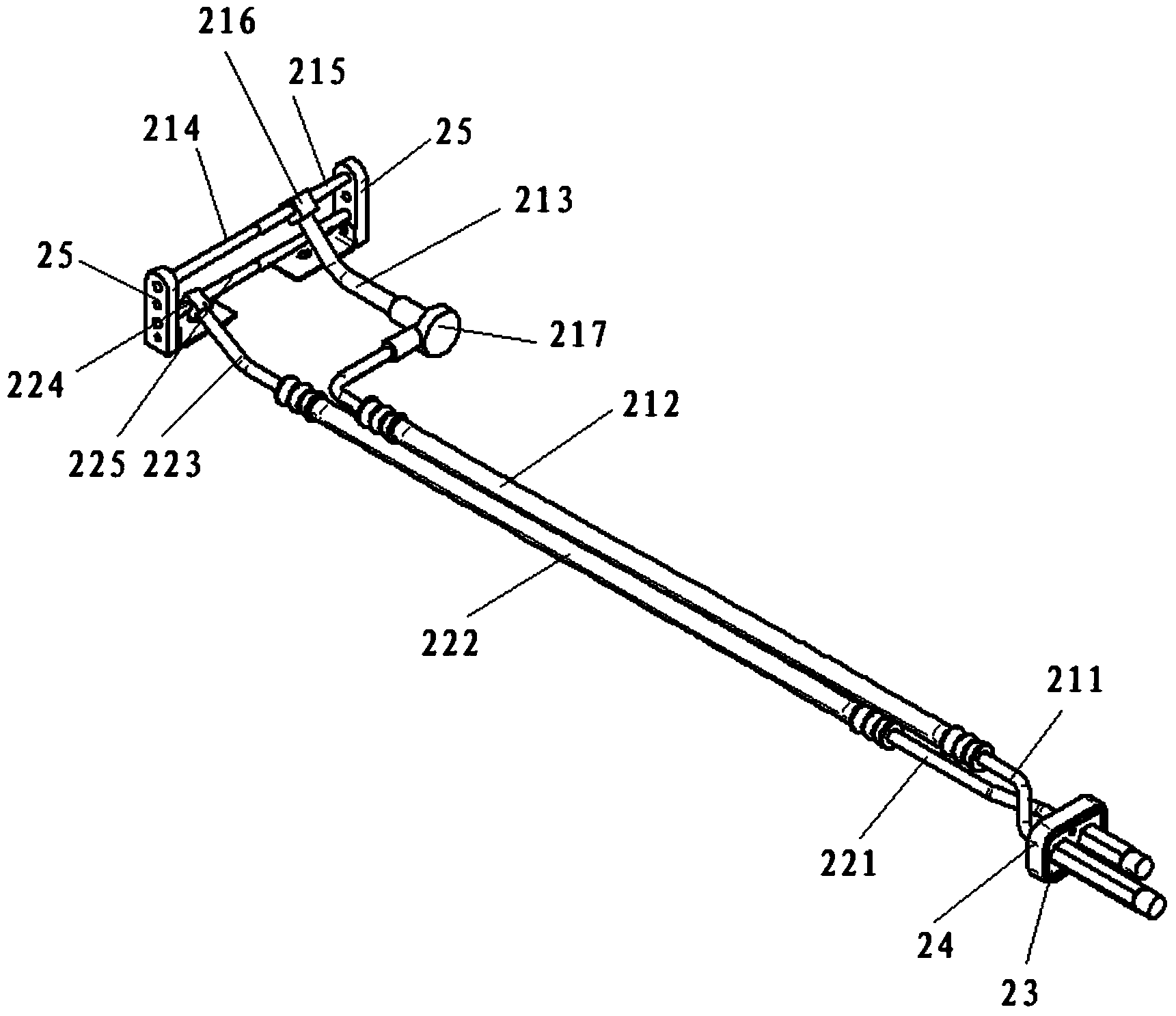

[0025] The evaporator assembly includes a refrigerant pipeline assembly 2 and a plurality of heat exchange core assemblies 1. The refrigerant pipeline assembly 2 includes a refrigerant inlet pipe 21 and a refrigerant outlet pipe 22. The output ends of the refrigerant inlet pipe 21 are divided and connected separately. The refrigerant inlet 141 of each heat exchange core assembly 1, the input end of the refrigerant outlet pipe 22 is divided and respectively connected to the refrigerant outlet 142 of each heat exchange core assembly 1, each heat exchange core assembly 1 is connected in parallel to the refrigerant pipe On the road assembly 2. The parallel structure design of the heat exchange core is adopted, and the temperature of the left and right heat exchange cores is uniform. The refrigerant between the left and right heat exchange cores i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com