Device for constructing model in layer

A technology for constructing models and structures, which is applied in the field of devices for constructing models layer by layer, can solve problems such as troublesomeness, and achieve the effect of structural stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

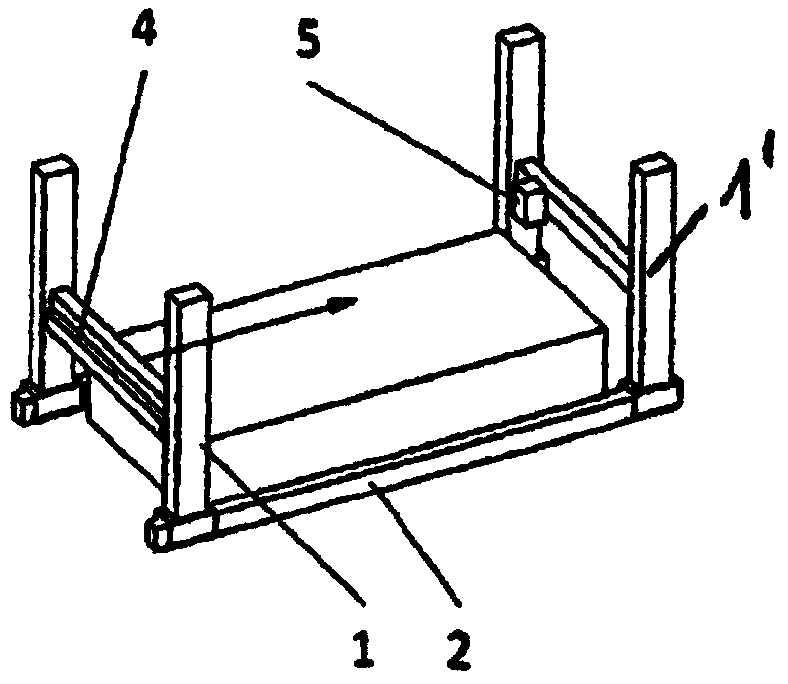

[0060] According to the invention, a device or method is described for producing a three-dimensional model on a plane by means of a 3D printing method, wherein a material application device (such as a granular material coater unit or a print head unit) is provided in order to apply the respective material Apply to flat surfaces. The material application device is then moved vertically according to the invention on one or more portals.

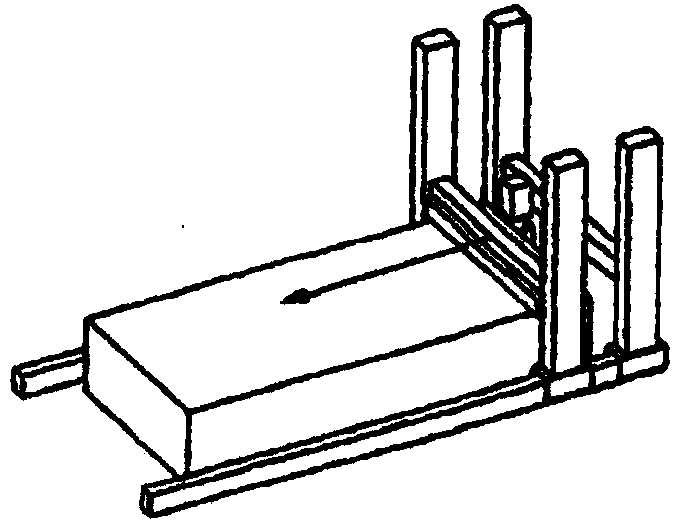

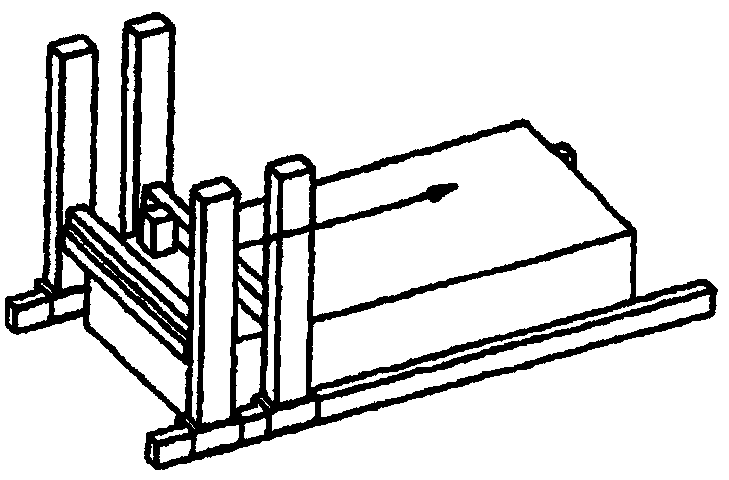

[0061] Figure 1 to Figure 4 The scheme of the method of the invention according to a preferred embodiment is shown. At this point, on the plane 9 , the granular material is coated onto the plane 9 with the coater 4 . At this time, the coater 4 is included in the portal frame 1 . The gantry 1 moves on the plane of the linear unit 2 . The portal frame 1 then moves back into its initial position (see figure 2 ). The gantry 1' containing the print head 5 is now also independently movable on the linear unit 2 fixedly connected to the bottom s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com