Battery manufacturing method and manufacturing device

A manufacturing method and storage battery technology, applied in secondary battery manufacturing, lithium storage batteries, non-aqueous electrolyte storage batteries, etc., can solve problems such as shortening production intervals, and achieve the effect of shortening production intervals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

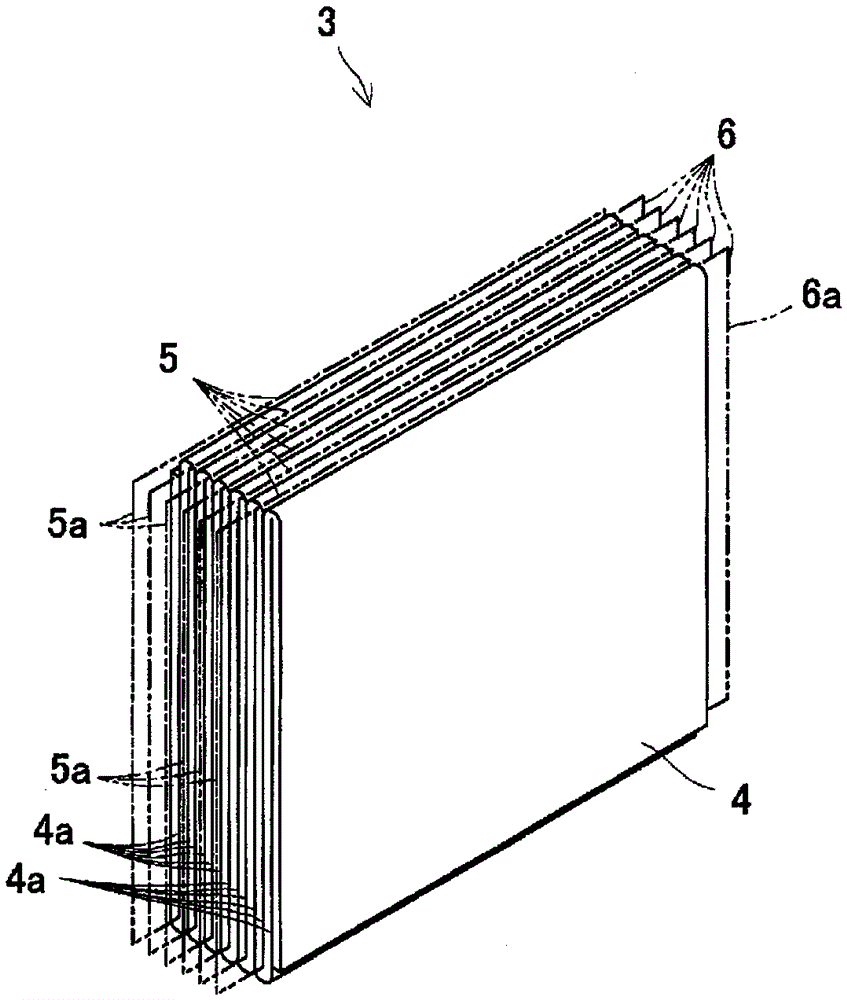

[0039] Such as figure 1 as well as figure 2As shown, a prismatic battery (battery) 1 as a lithium ion storage battery includes a prismatic case 2 , and an electrode plate group 3 is housed in the prismatic case 2 . A positive terminal and a negative terminal (not shown) are provided at predetermined positions of the rectangular case 2 . Furthermore, an electrolytic solution obtained by mixing a lithium salt with an organic solvent is filled in the rectangular case 2 .

[0040] The electrode plate group 3 includes a separator 4 that is bent in a zigzag shape, and positive electrode plates 5 and negative electrode plates 6 that are alternately inserted into the valley grooves 4 a of the separator 4 . The positive electrode plates 5 and the negative electrode plates 6 are stacked alternately with the separators 4 interposed therebetween, and the separators 4 are stacked flat. The positive electrode plate 5 and the negative electrode plate 6 have lead portions 5a, 6a protrudin...

Embodiment approach 2

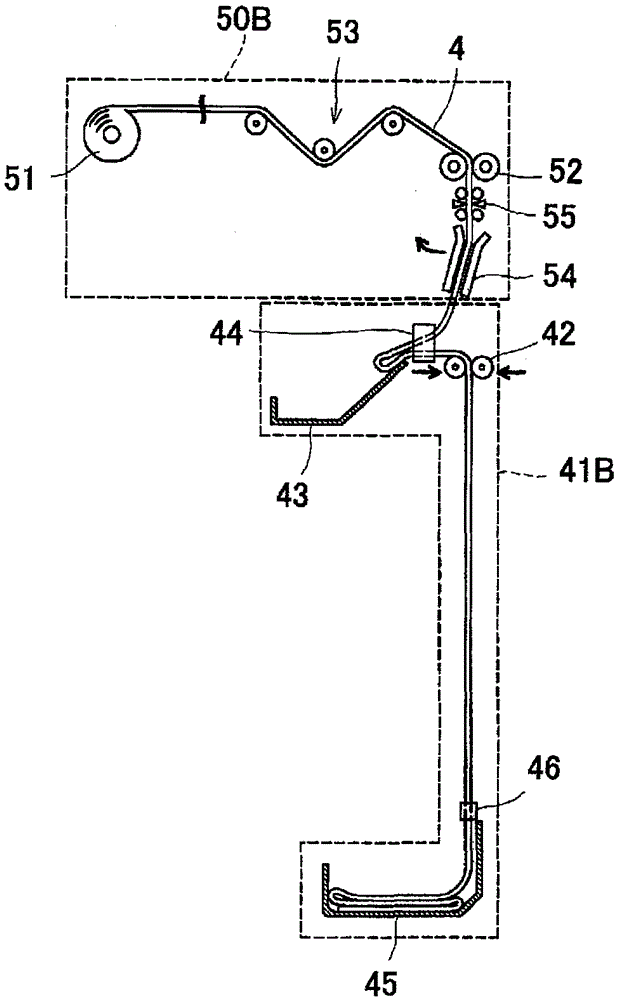

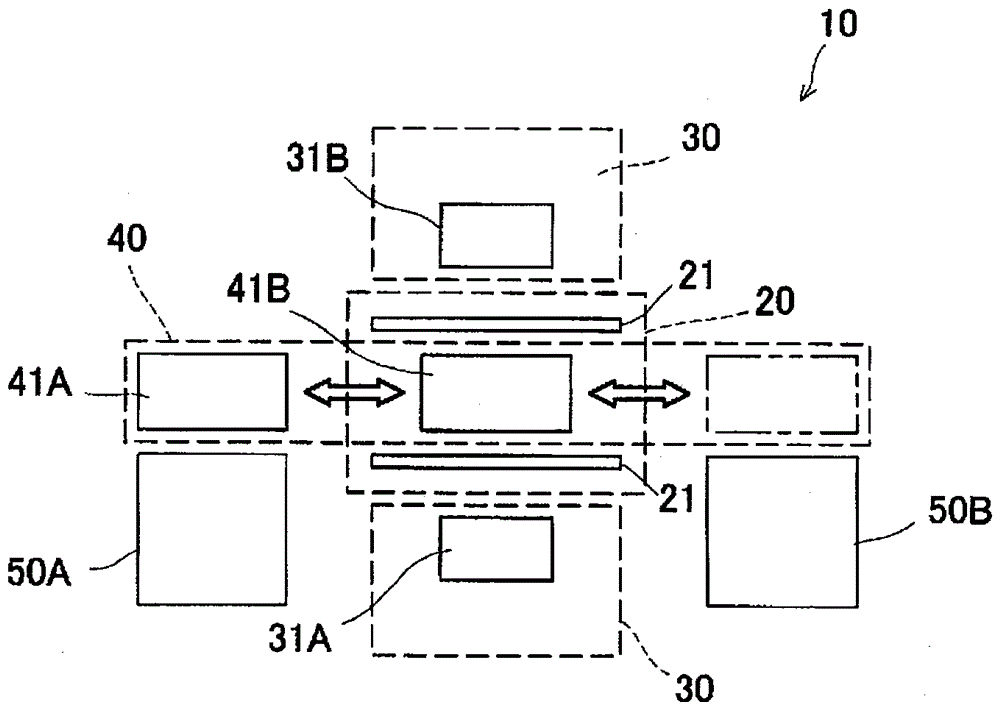

[0071] Figure 13 It is a schematic diagram showing the manufacturing apparatus of the electrode plate group concerning Embodiment 2. In addition, the same code|symbol is attached|subjected to the same member, and overlapping description is abbreviate|omitted.

[0072] The manufacturing apparatus 10A according to this embodiment is such as Figure 13 As shown, one supply mechanism 50 is provided for one zigzag bending mechanism 20 , and the conveyance mechanism 40A is also provided with one holding and conveying member 41 corresponding to the one supply mechanism 50 . The structure holding the transport member 41 is the same as that of the first embodiment, but differs from the first embodiment in that it is fixed at a position facing the zigzag bending mechanism 20 and does not move.

[0073] In this manufacturing apparatus 10A, the separators 4 are supplied and held by the holding and conveying means 41 in the same procedure as in the first embodiment (see Figure 7 ~Figu...

Embodiment approach 3

[0077] Figure 14 is a schematic diagram showing an electrode group according to Embodiment 3, Figure 15 It is a schematic diagram showing the manufacturing apparatus according to Embodiment 3. In addition, the same code|symbol is attached|subjected to the same member, and overlapping description is abbreviate|omitted.

[0078] Such as Figure 14 As shown, the electrode plate group 3A according to Embodiment 3 is a stacked body including a continuous stacked body 100 bent in a zigzag shape and a positive electrode plate 5 inserted into each tooth valley groove 100 a of the stacked body 100 . constituted. The laminated body 100 is a laminated body in which the negative electrode plate 6A is sandwiched between two separators 4A. Therefore, the positive electrode plate 5 inserted into each valley groove 100a of the stacked body 100 faces the negative electrode plate 6A via the separator 4A.

[0079] In addition, even in such a structure of the present embodiment, as in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com