Beverage filling method

A beverage and filling machine technology, which is applied in the field of beverage filling, can solve the problems of many processes or time, difficulty in maintaining and managing sterility, and high price of sterilization filters, so as to improve production efficiency and shorten production intervals.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

[0040] Hereinafter, Embodiment 1 of the present invention will be described with reference to the drawings.

[0041] First, the structure of the aseptic beverage filling device will be described, and then the method of cleaning and sterilizing the device will be described.

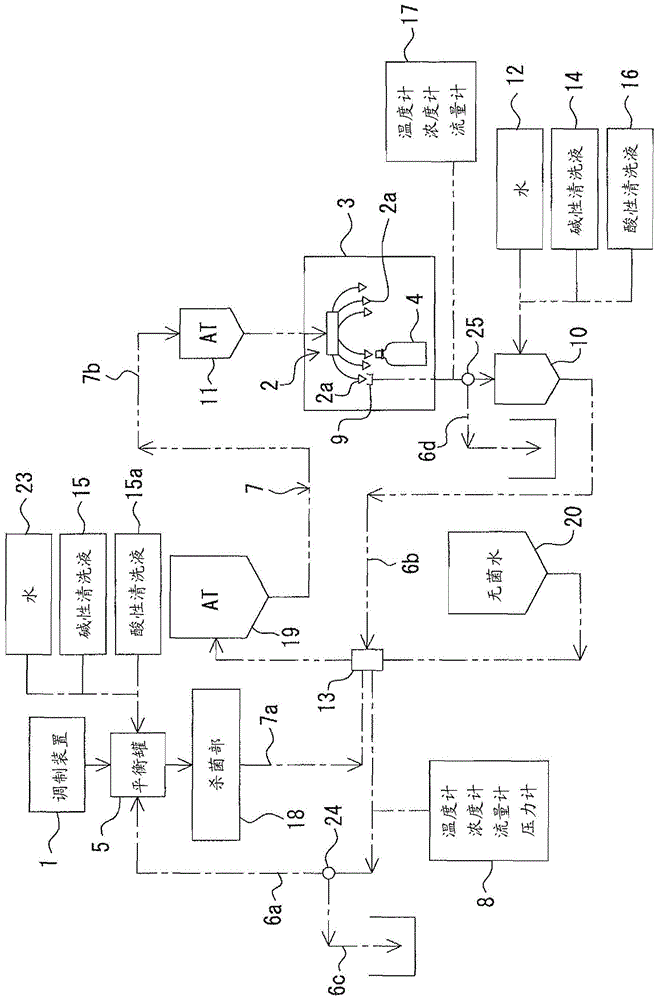

[0042] Such as figure 1 As shown, the aseptic beverage filling device has a beverage preparation device 1 and a filling machine 2 for filling beverages into bottles 4 . The brewing device 1 and the filling nozzle 2 a in the filling machine 2 are connected by a beverage supply system pipe 7 . Furthermore, the filling machine 2 is surrounded by a sterile chamber 3 .

[0043] The brewing device 1 is used to prepare beverages such as tea drinks, fruit drinks, and sports drinks in respective desired mixing ratios, and since it is a known device, its detailed description will be omitted.

[0044] The filling machine 2 is configured by disposing a plurality of filling nozzles 2a around a wheel (not shown) that...

Embodiment 1

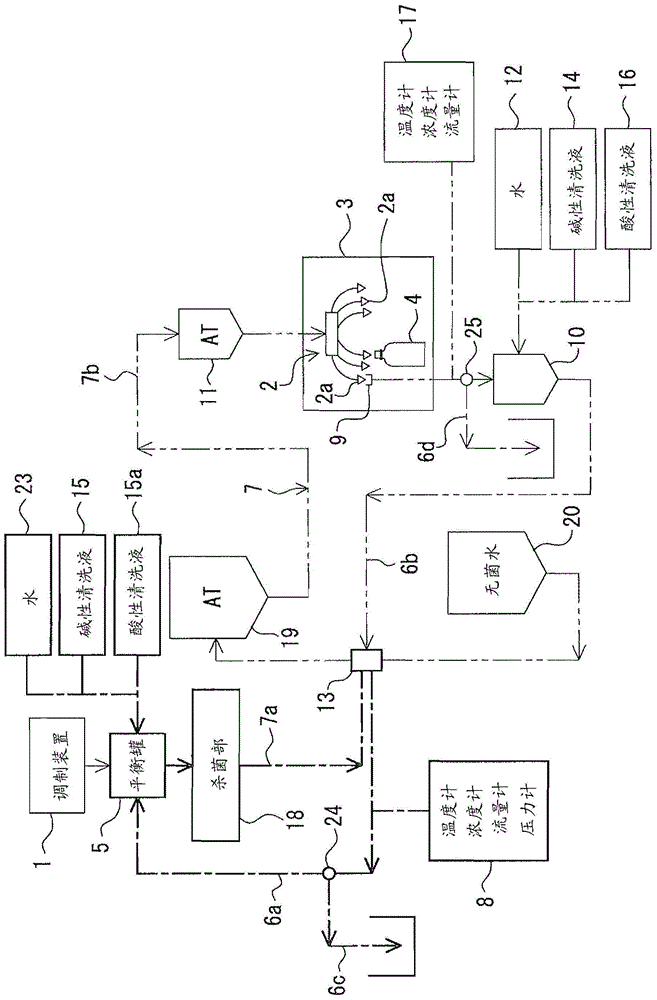

[0088] Fill the sterilized beverage into a 500mL beverage bottle sterilized in an aseptic environment, and seal it with a sterilized bottle cap in a 600bpm (bottle per minute) beverage filling device. After drinking black tea with milk and sugar, in figure 2 A 4% by mass sodium hydroxide alkaline cleaning solution was prepared in the balance tank 5 shown by the middle thick line, and the temperature in the passage of the thick line was set at 85° C., and it was circulated for 30 minutes.

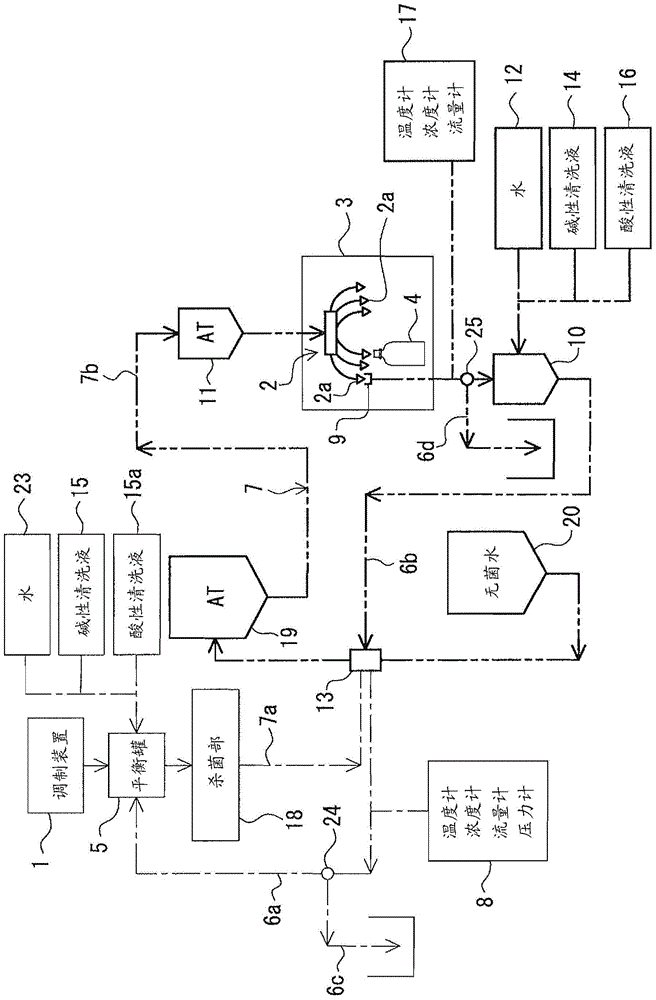

[0089] In addition, in image 3 A 4% by mass sodium hydroxide alkaline cleaning solution was prepared in the balance tank 10 shown by the middle thick line, and the temperature in the passage of the thick line was set at 85° C., and it was circulated for 30 minutes.

[0090] Afterwards, by delivering normal-temperature sterile water from the sterile water tank 20 to the balance tank 5, according to Figure 4 The thick line passage in the middle is sent liquid and is cleaned, and after clean...

Embodiment 2

[0092] Fill the sterilized beverage into a 500mL beverage bottle sterilized in an aseptic environment, and seal it with a sterilized bottle cap in a 600bpm beverage filling device. After filling the green tea beverage for 20 hours, figure 2 A 2% by mass sodium hydroxide alkaline cleaning solution was prepared in the balance tank 5 shown by the middle thick line, and the temperature in the passage of the thick line was set at 85° C., and it was circulated for 20 minutes.

[0093] In addition, in image 3 Prepare a 2% by mass sodium hydroxide alkaline cleaning solution in the balance tank 10, set the temperature in the thick line passage to 85° C., and circulate it for 20 minutes. Afterwards, by delivering normal-temperature sterile water from the sterile water tank 20 to the balance tank 5, according to Figure 4 The thick line channel in the machine is cleaned by feeding liquid, and then the barley tea beverage is filled into the beverage bottle continuously for 15 hours. N...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com