Microporous laser pellet processing method and device based on temperature rise regulation and control

A laser processing method and target shot technology, applied in laser welding equipment, metal processing equipment, manufacturing tools, etc., can solve the problems of inability to process non-metallic materials, low processing efficiency, micro-cracks in the target shot, and easy control of processing parameters. , to ensure stability, the effect of small heat affected zone

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

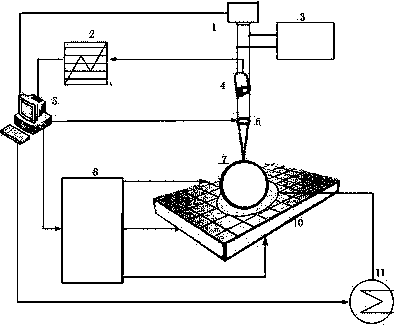

[0036] A microhole laser processing method for target pellets based on temperature rise regulation:

[0037] Drill holes in the target pellets with ultraviolet laser, ultrashort pulse laser or femtosecond laser;

[0038] Adjust the repetition frequency, power and pulse width of the laser through the laser power supply;

[0039] Real-time monitoring of pellet processing through high-resolution CCD;

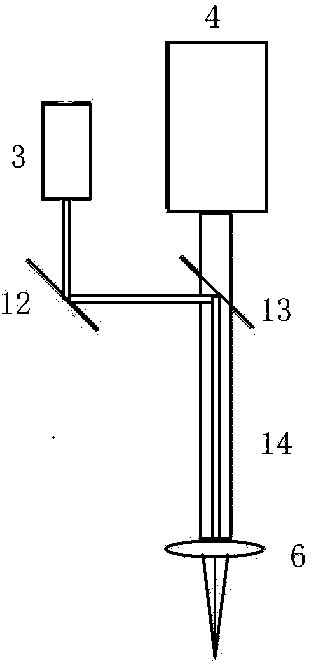

[0040] Use a microscope objective to focus the laser on the surface of the target pellet to be processed;

[0041] The target pellet is placed on the suction cup with heating function, and the three-dimensional precision micro-motion table on the suction cup is controlled to move along the three directions of X / Y / Z to realize the micro-motion adjustment of the target pellet;

[0042] The temperature of the heating sucker is adjusted by the temperature control system, and the temperature of the target is controlled, so that the pressure generated by the internal pres...

Embodiment 2

[0044] In the method of micro-hole laser processing of target pellets based on temperature rise control described in Example 1, when the ultraviolet laser is used to drill holes in the target pellets, the material of the target pellets with a fixed size is etched away by controlling the number of laser pulses.

Embodiment 3

[0046] In the method for processing target pellet micropores based on temperature rise regulation described in embodiment 1 or 2, the laser used is ultraviolet laser, ultrashort pulse laser or femtosecond laser, and when it interacts with the target pellet, photothermal and photochemical ablation occur. , to precisely control the erosion amount of the micropores of the target pellet.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com