Method for machining advanced grouting block hole of shield tunneling machine

A technology of advanced grouting and processing methods, applied in the processing field, can solve the problems of chip removal and cooling difficulty, and achieve the effects of reducing processing costs, reducing man-hour consumption, and improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

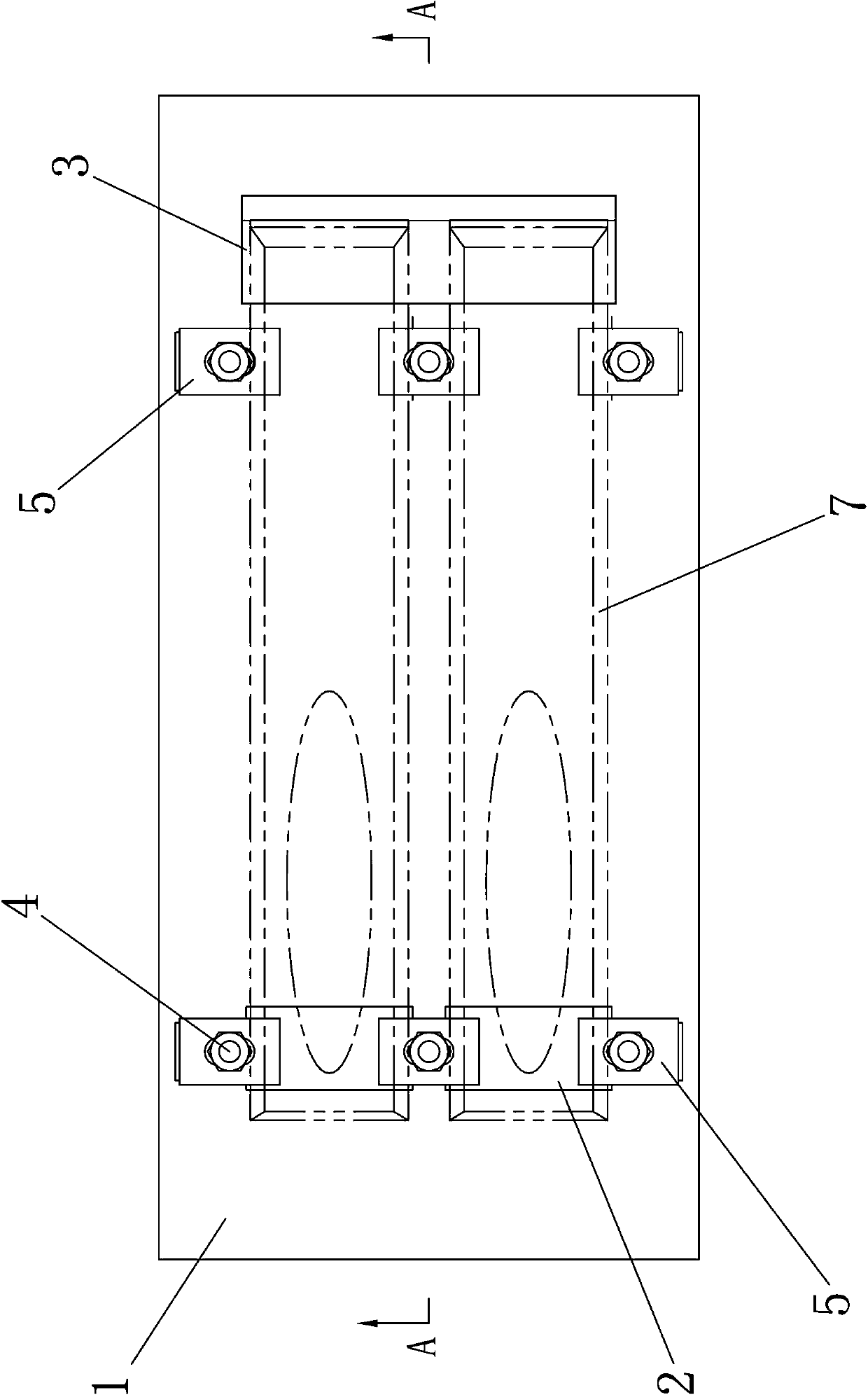

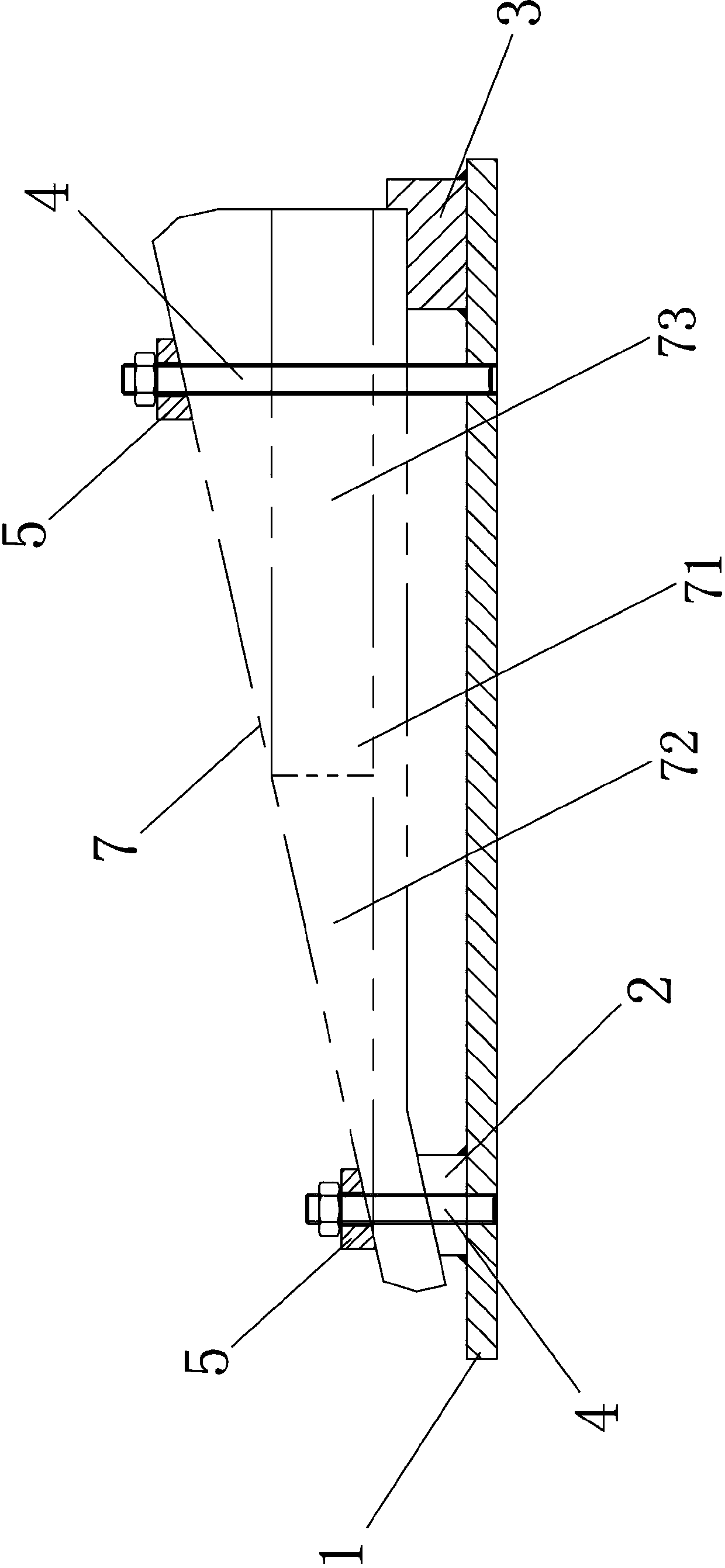

[0012] Such as figure 1 , figure 2 Shown: a processing method for the advance grouting block hole of the shield machine, the specific method is as follows: the first step, tooling production: welding two left pads 2 on the left side of the tooling base plate 1, and welding one right pad on the right side of the tooling base plate Pad block 3, to ensure that the central axis of the grouting block hole 71 required for the grouting block 7 is on the horizontal plane, and drill six M30 tooth holes on the bottom plate 1 for the bolt 4 connection of the briquetting block 5; The contact surface of the grout block 7 is processed into a slope to fit the slope of the grout block 7; the second step, the processing process: on the basis of the assembly of the tooling and the clamping of the undrilled grout block 7, the left slope hole 72 uses a small-diameter milling cutter to mill the hollow, and simulates the shape of the inclined hole 72 according to the mode of milling depth in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com