Repair method for flanged wheel and repaired flanged wheel

A repair method and flange technology, applied in the direction of wheels, wheels characterized by rail running parts, vehicle parts, etc., can solve the problems of difference in service life between wheel rim and wheel tread, labor time consumption, high wear speed, etc., to achieve reduction Repair and maintenance costs, improved replacement efficiency, and low manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

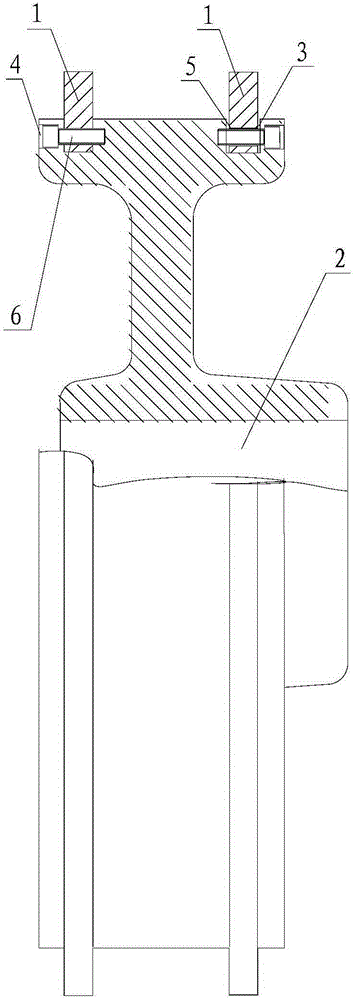

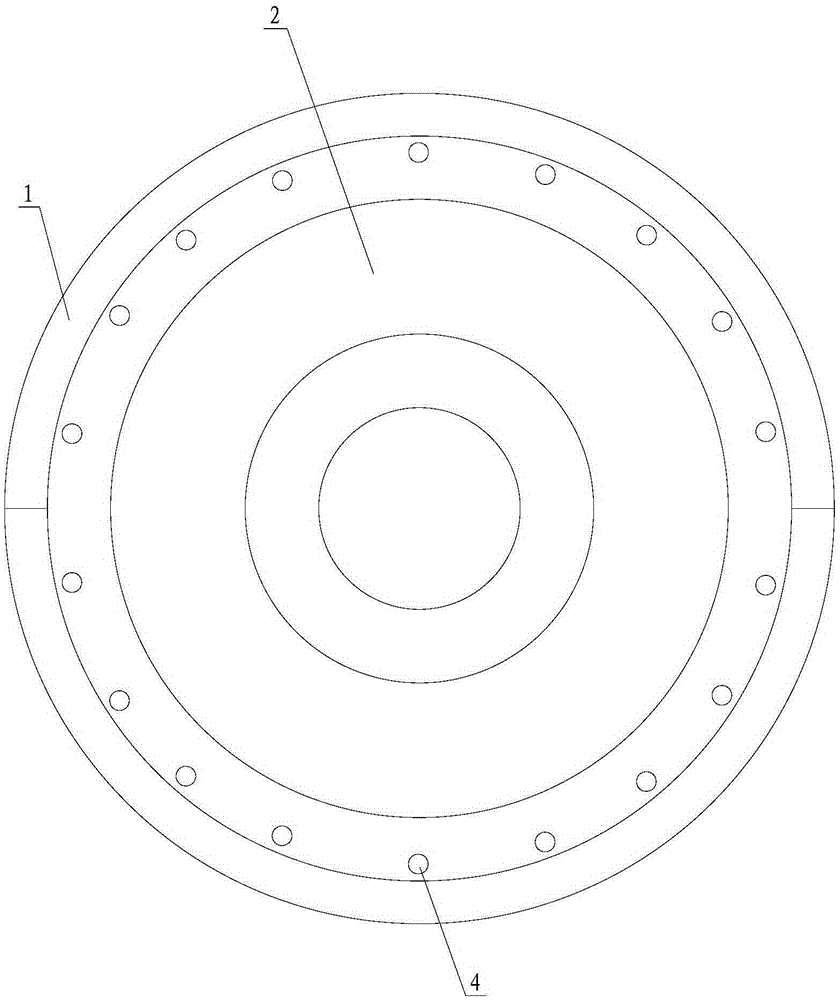

[0019] like figure 1 , figure 2 Shown is a flanged wheel repaired by the method for repairing the flanged wheel with simple repairing operation and low repair and maintenance cost provided by the present invention. Repair method described in the present invention comprises the following steps,

[0020] a. Determine the parameters, calculate and determine the thickness and height of the flange 1 for replacement according to the thickness of the flange 1 of the existing wheel, the height of the flange 1 and the design parameters, and according to the thickness and height of the flange 1 for replacement The height determines the depth and width of the installation groove 3 used for installing the flange 1 on the wheel body 2;

[0021] b. Process the flange and the installation groove, process the flange 1 according to the parameters of the flange 1 for replacement determined in step a, and process the flange 1 according to the parameters of the installation groove 3 for instal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com