Multi-objective optimization method of engine mounting system

An engine mount, multi-objective optimization technology, applied in the fields of motor vehicles, special data processing applications, instruments, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0066] The present invention will be further described in detail below through an example in conjunction with the accompanying drawings.

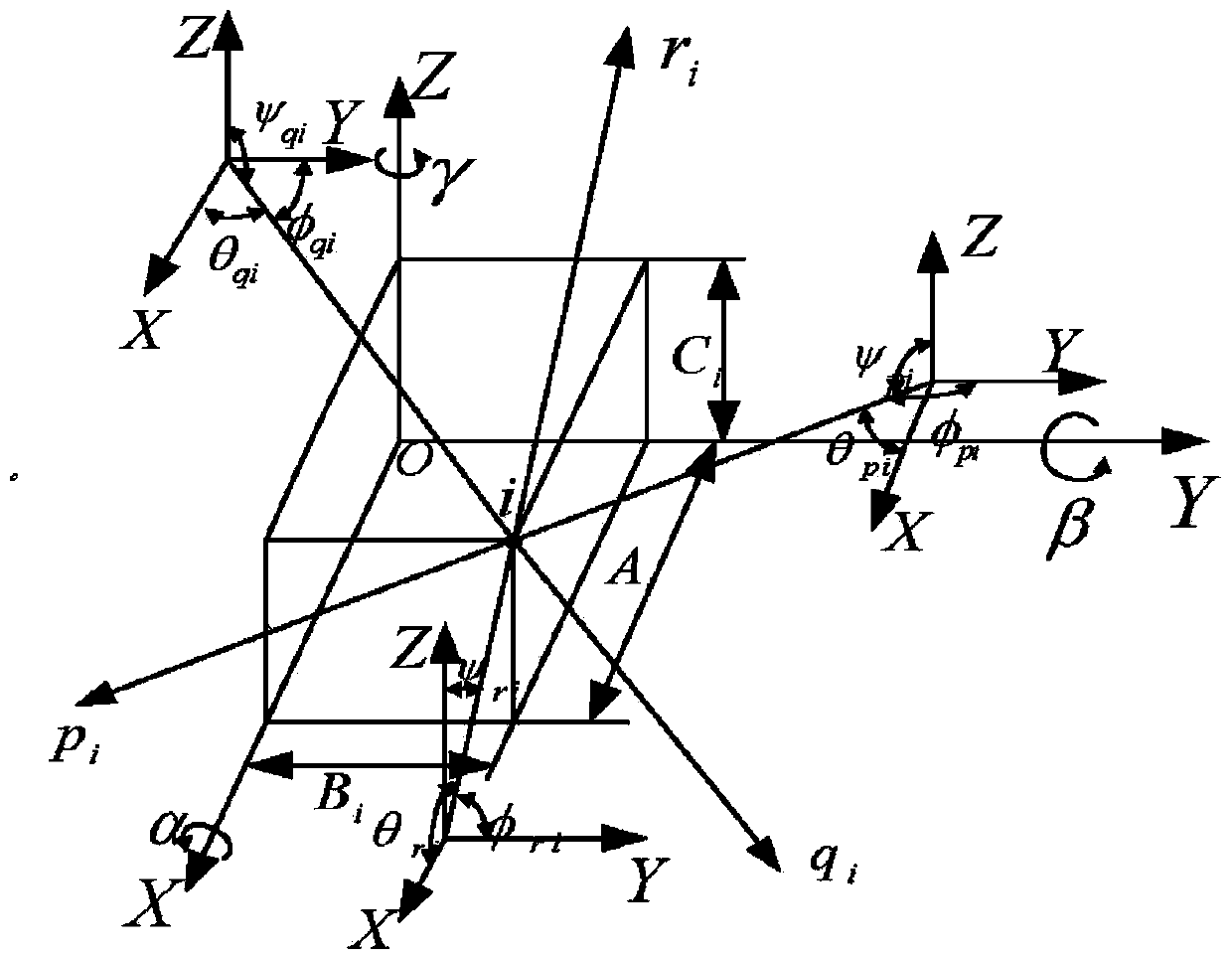

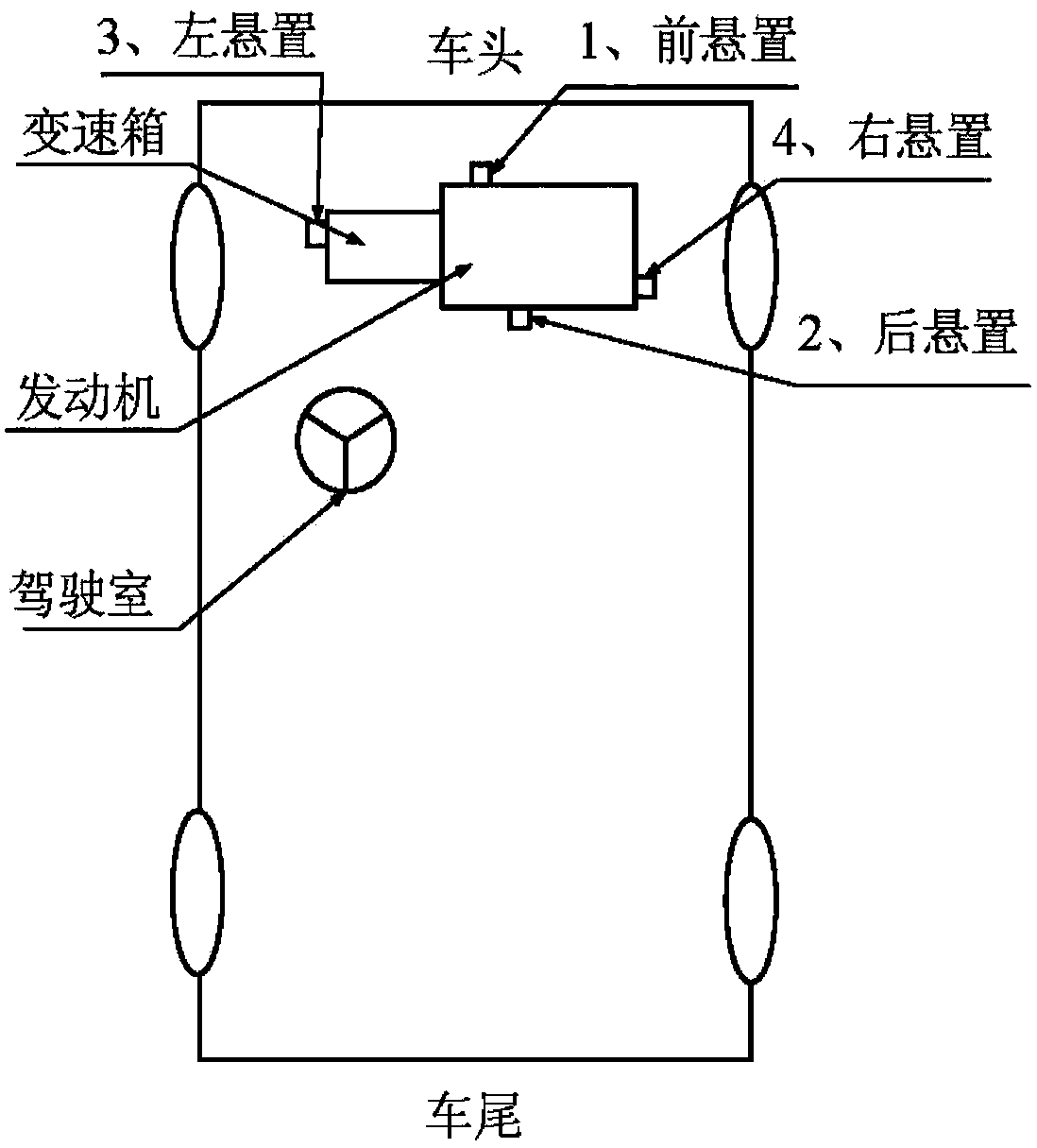

[0067] established as figure 1 The general layout space of the engine mount system is shown, where the i point is the i-th mount point, O is the public center of mass of the powertrain, OXYZ is the reference coordinate system taken by the research object of this paper, and the public center of mass is taken, Pointing to the direction of the cab (perpendicular to the crankshaft) is the X direction, pointing to the front end of the engine, parallel to the crankshaft is the Y direction, and vertically upwards is the Z direction. α, β, γ are the rotation angles of the suspension system around the OX axis (roll), OY axis (pitch) and OZ axis (yaw) respectively in the reference coordinate system (take the direction of the vector arrow as positive). A i , B i 、C i is the arrangement position of any (i-th one in the figure) suspended in the refe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com