Multi-pressure ship

A ship and bow technology, applied in the direction of hull, hull design, ship construction, etc., can solve the problems of ship size limitation, difficulty in speed increase, etc., and achieve the effect of reducing freight cost and improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

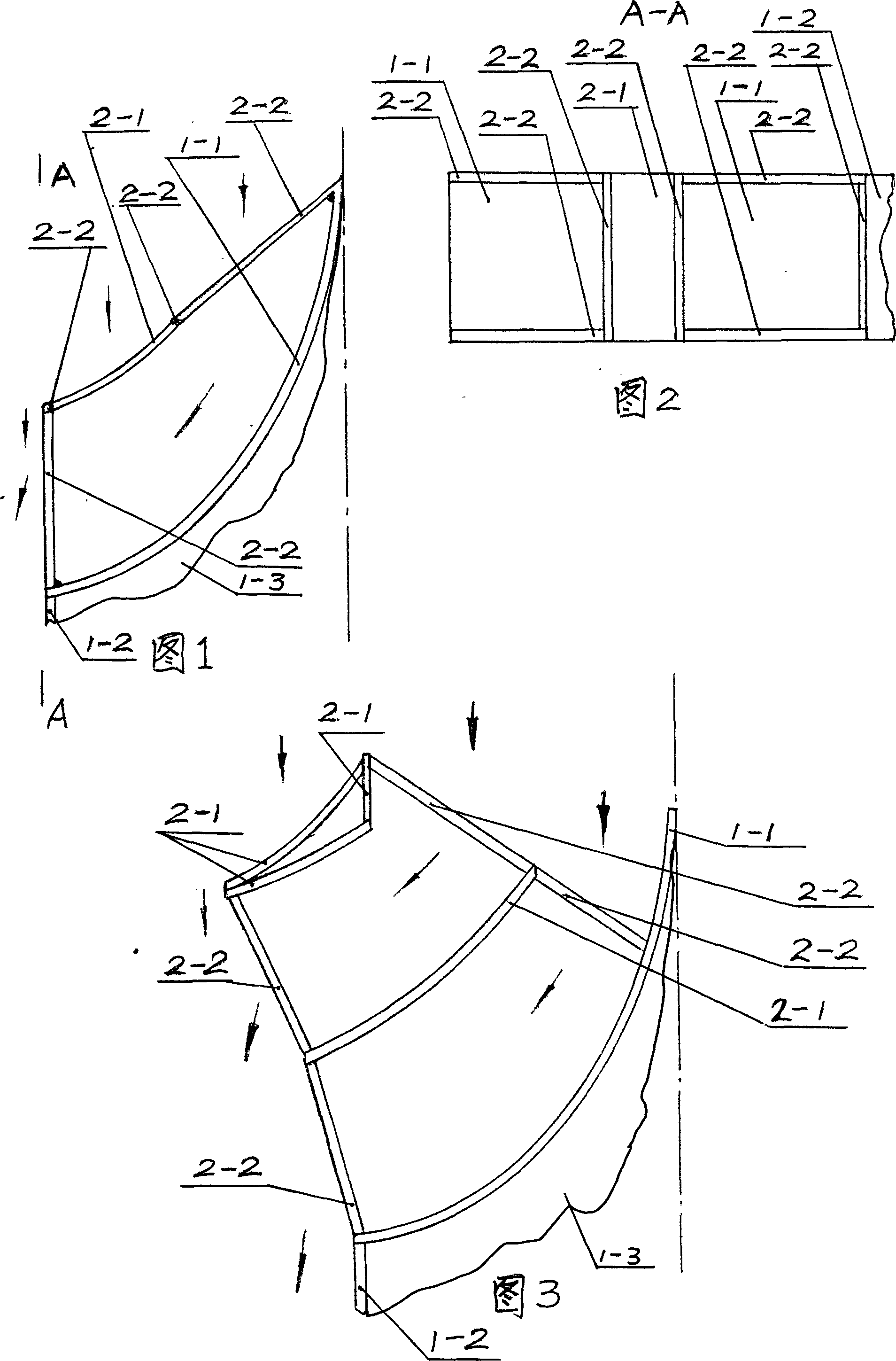

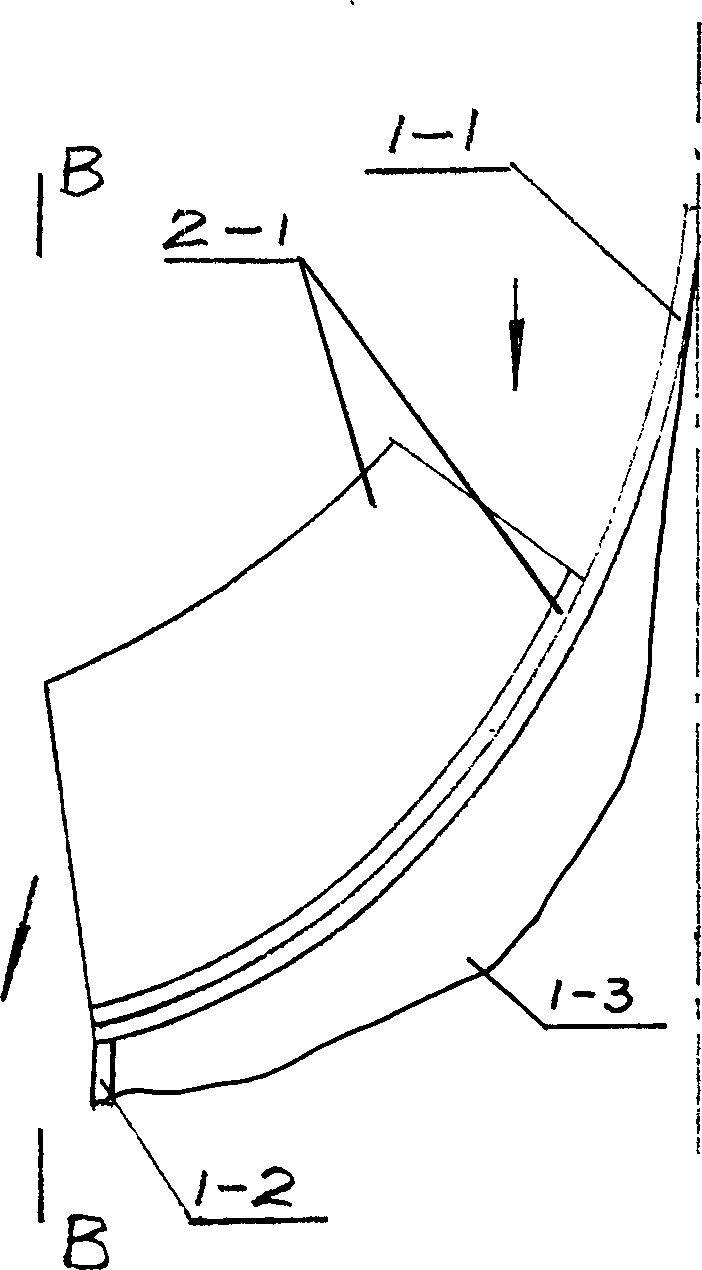

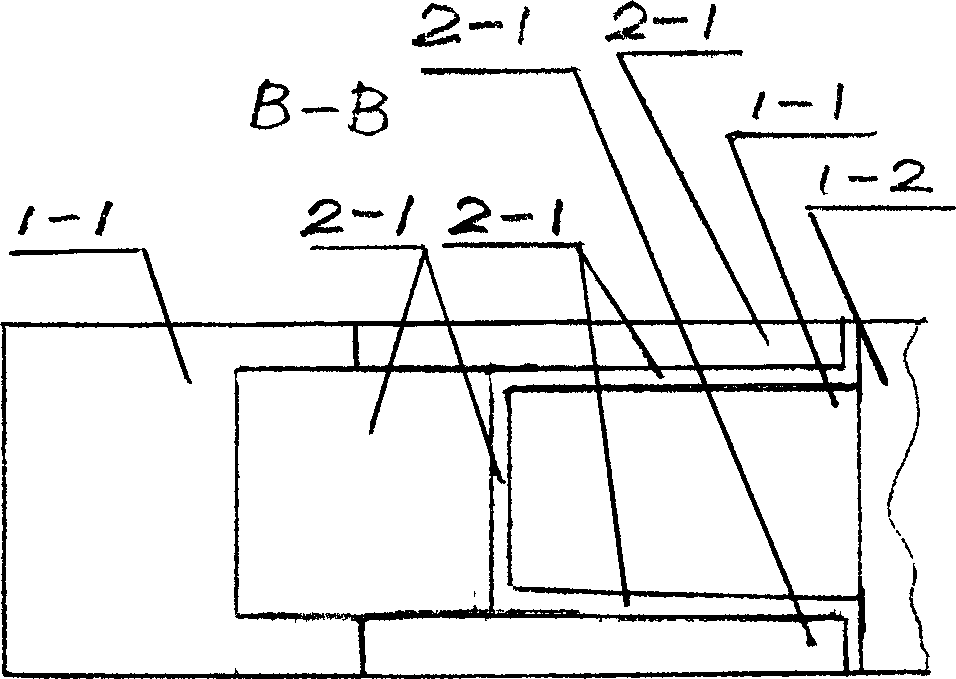

[0020] For convenience, only the left part of the symmetrical part of the bow is drawn for description, and the direction of the arrow is the flow direction of the water.

[0021] in the attached figure 1 And attached figure 2 In the shown first embodiment, the multi-pressure vessel of the present invention comprises a hull section (1) and a flow distribution section (2). The hull part (1) comprises a bow plate (1-1), a side plate (1-2) and a board on a ship (1-3), and the splitter part (2) comprises a pressure dividing plate (2-1) and a support bar ( 2-2); the bow plate (1-1) is the plate surface of the two directions in front of the ship, and the side plate (1-2) is the plate surface of the hull position. The ship side plate (1-2) links with the bow plate (1-1); the upper plate (1-3) connects the ship side plate (1-2) and the bow plate (1-1) on two sides of the ship Link; Partial pressure plate (2-1) links with bow plate (1-1) by support bar (2-2). When the ship was sai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com