Process for producing high-purity gadolinium chloride through fuzzy linkage extraction separation

A gadolinium chloride and linkage technology is applied in the field of fuzzy linkage extraction and separation to produce high-purity gadolinium chloride products, which can solve the problems of high acid-base consumption, large amount of rare earth pressing, and large sum of organic phase and water phase, etc. Achieve the effect of reducing acid and alkali consumption, low acid and alkali consumption in operation, and reducing the amount of rare earth pressing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

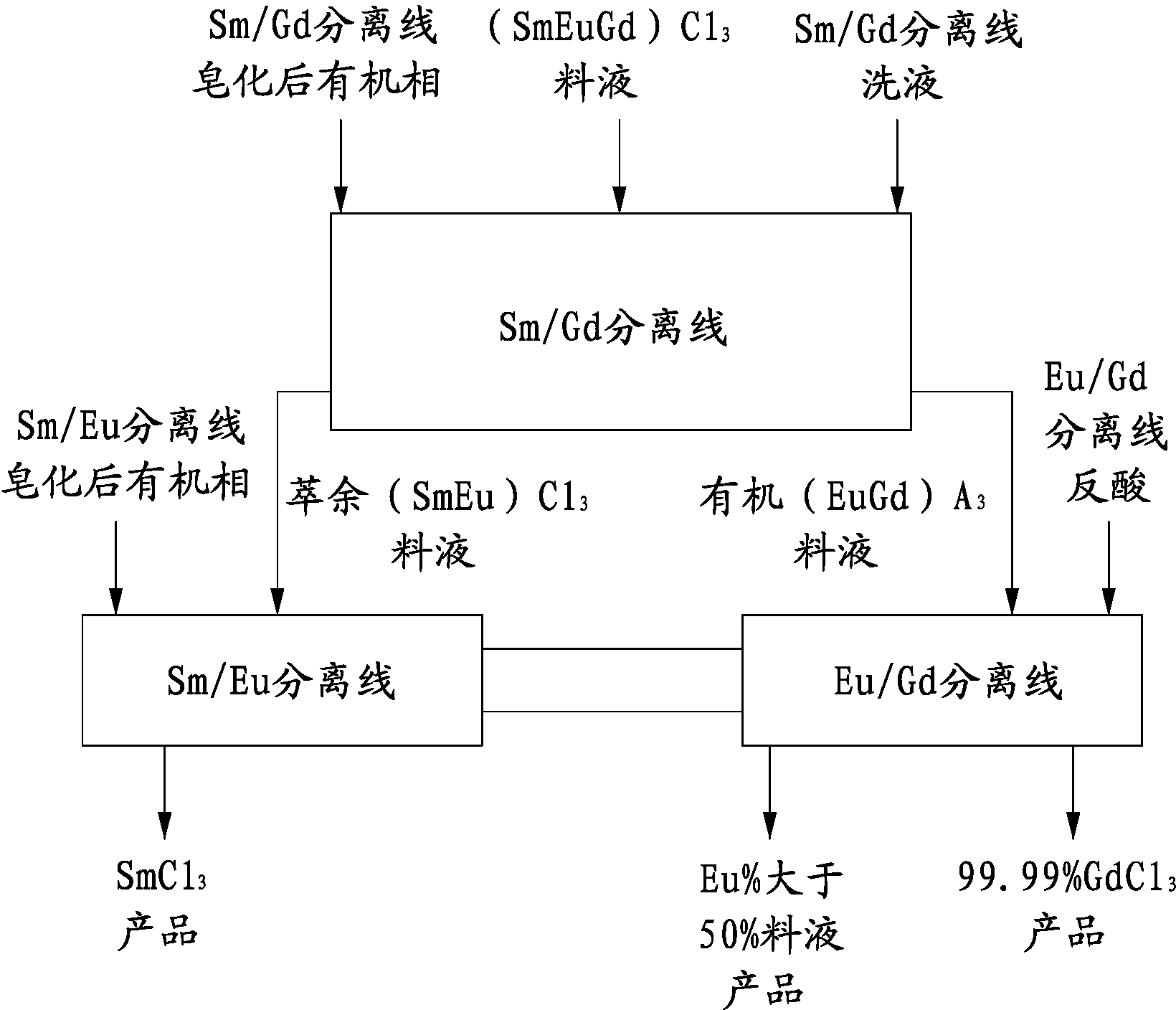

[0014] Such as figure 1 As shown, a fuzzy linkage extraction separation process disclosed by the present invention to produce high-purity gadolinium chloride consists of three production lines, namely Sm / Gd separation line, Sm / Eu separation line, and Eu / Gd separation line.

[0015] (SmEuGd)Cl 3 The feed liquid is first pretreated by the Sm / Gd separation line to achieve the separation of Sm and Gd elements.

[0016] (SmEu)Cl at the raffinate outlet of the Sm / Gd separation line 3 The feed liquid enters the Sm / Eu separation line, and the (EuGd) A of the organic outlet of the Sm / Gd separation line 3 The feed liquid enters the Eu / Gd separation line, the Sm / Eu separation line and the Eu / Gd separation line are connected in series, (SmEu)Cl 3 Feed liquid enters Sm / Eu separation line and (EuGd)A 3 After the feed liquid enters the Eu / Gd separation line (wherein A is the abbreviation of the organic extractant functional group in the industry, representing organic matter), the SmCl 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com