Self-traveling equipment train used for fully mechanized coal mining face

A fully-mechanized mining face and equipment technology, applied in the field of self-moving trains for fully-mechanized mining face equipment, can solve problems such as transportation problems, slow moving speed, and potential safety hazards, so as to improve mobility, improve stability, and prevent self-slipping Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

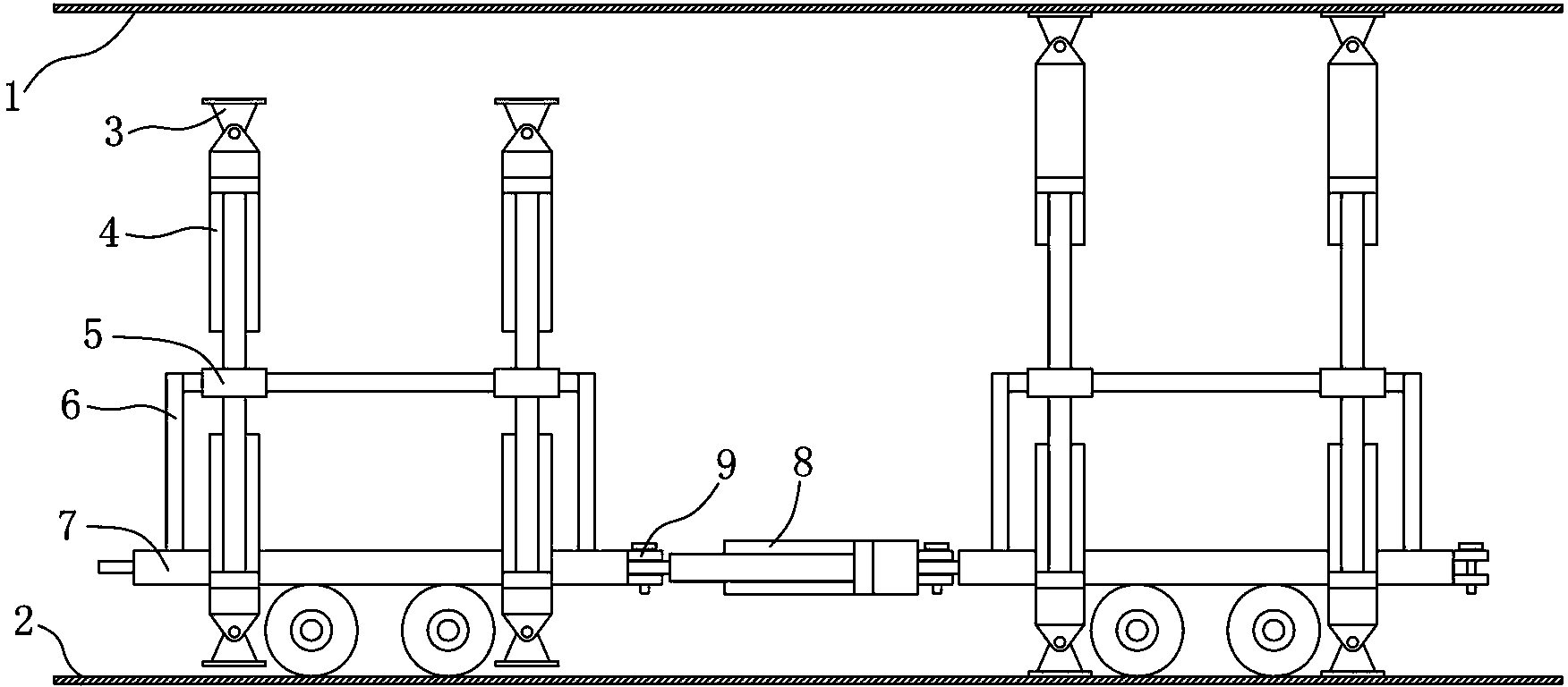

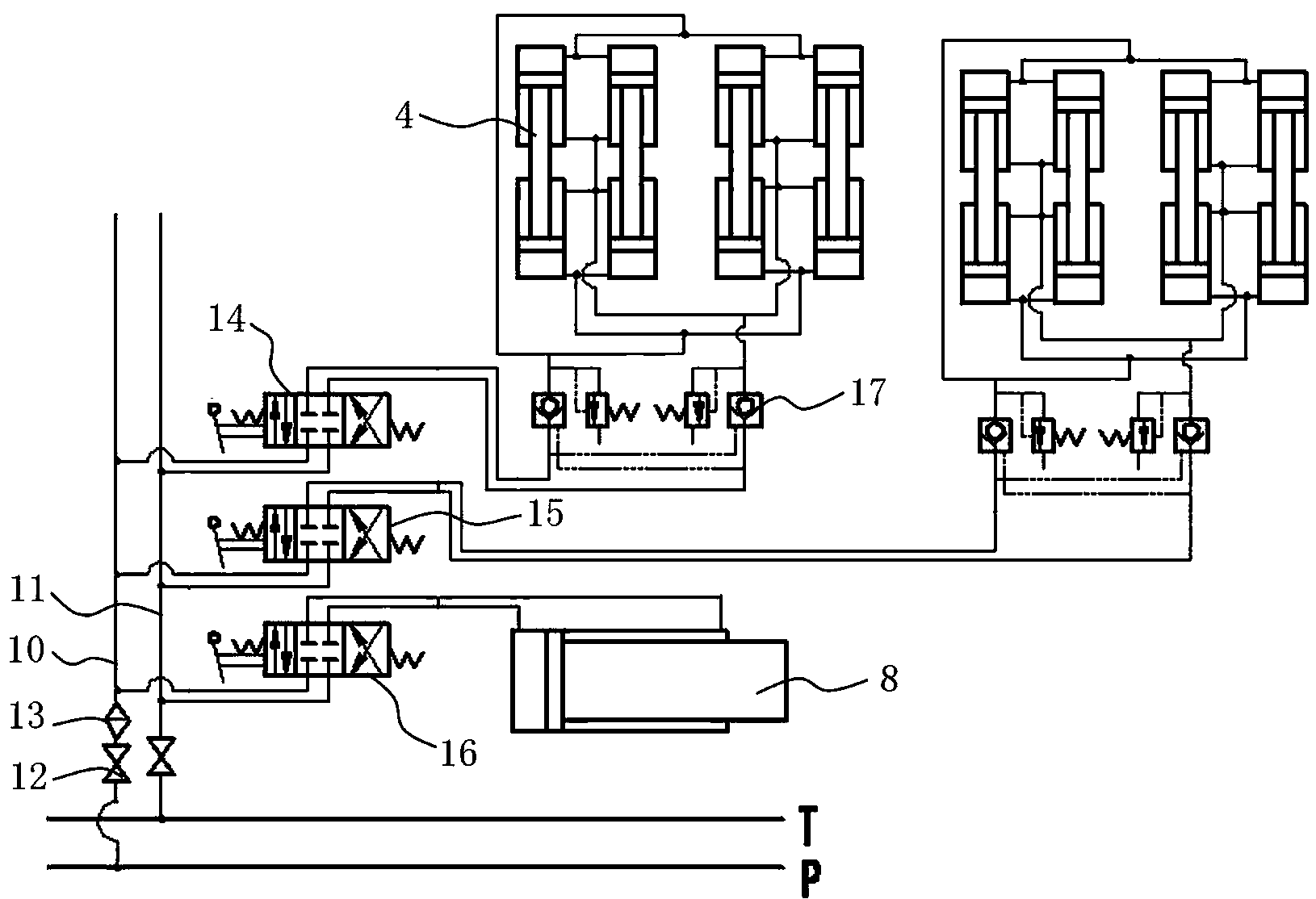

[0024] like Figure 1-3 It shows that a comprehensive mining work surface equipment described in the embodiment of the present invention mainly includes two flat -panel cars connecting two front and rear sections 7, horizontal shift device, support device, connection framework 6, and hydraulic control system.

[0025] The cross -shift device mainly includes a transverse hydraulic cylinder 8, and the two ends of the horizontal shift hydraulic cylinder 8 are connected to two tablet cars 7 through the hinge bearing 9 to drive the two tablet cars 7 before and after.

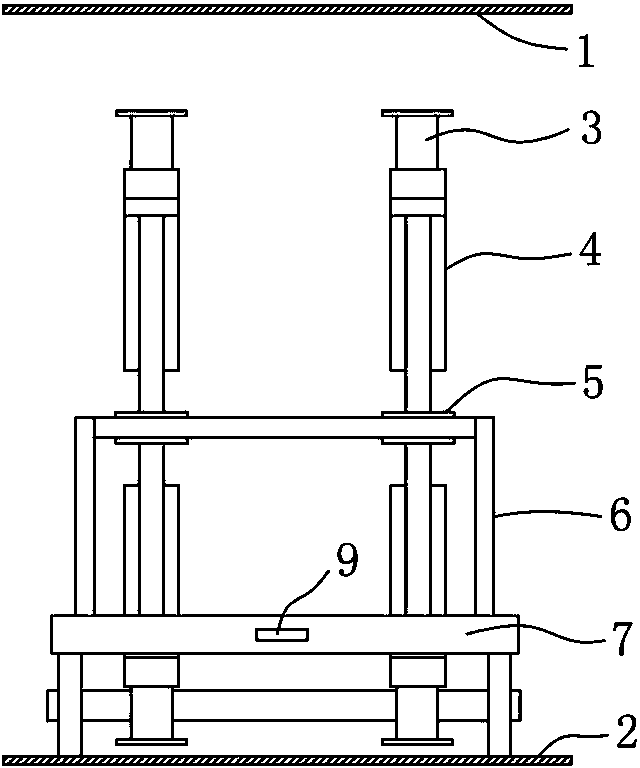

[0026] The supporting device mainly includes four hubbing pillars 4, four hydraulic pillars 4 in the four corners of the tablet 7.The hydraulic pillars 4 are mainly composed of two upper and lower piston cylinders in series.The piston rod is fixed on the connection frame 6 of each tablet 7 through the hug 5 vertical. The upper and lower ends of the Pistons are equipped with one earrings support 3, earrings support 3 and t...

Embodiment 2

[0036] The embodiments of this embodiment 1 are basically the same. The difference is that the hydraulic pillar 4 is mainly composed of two upper and lower piston tanks in series. The upper and lower covary of the piston rod of the two piston cylinders is relatively and fixed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com